Inner barrel body used for environment-friendly fireworks

A technology of environmentally friendly fireworks and inner cylinders, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems that affect the production efficiency of fireworks, increase the cost of fireworks, and complicate the manufacturing process, so as to achieve better launch effects, shorten manufacturing time, good launch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

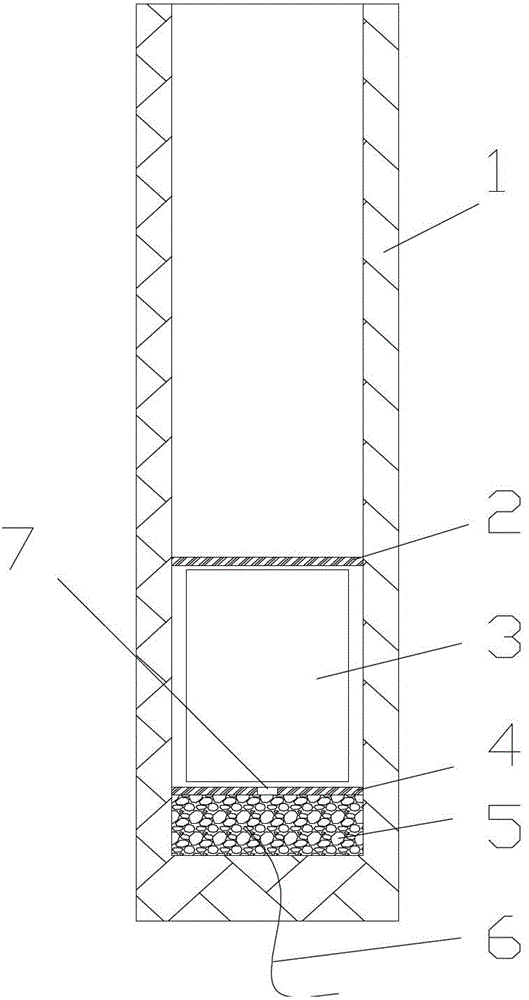

[0024] see figure 1 , the structure of the existing fireworks is that an inner cylinder body 3 is housed in the launch tube 1, the upper end of the inner cylinder body 3 is covered with an upper cardboard 2, and the lower end is placed with a lower cardboard 4, between the lower cardboard 4 and the bottom of the launch tube 1 The propellant 5 is installed between them, the propellant 5 is provided with a lead wire 6, and the lower cardboard 4 is provided with a through hole 7, so that the lead wire of the inner cylinder body 3 can be ignited conveniently when the propellant is burned, and the inner cylinder body 3 can be ignited when the propellant 5 is burned. The body 3 is launched into the air, and the inner cylinder body 3 explodes and burns in the air to produce brilliant and colorful colors.

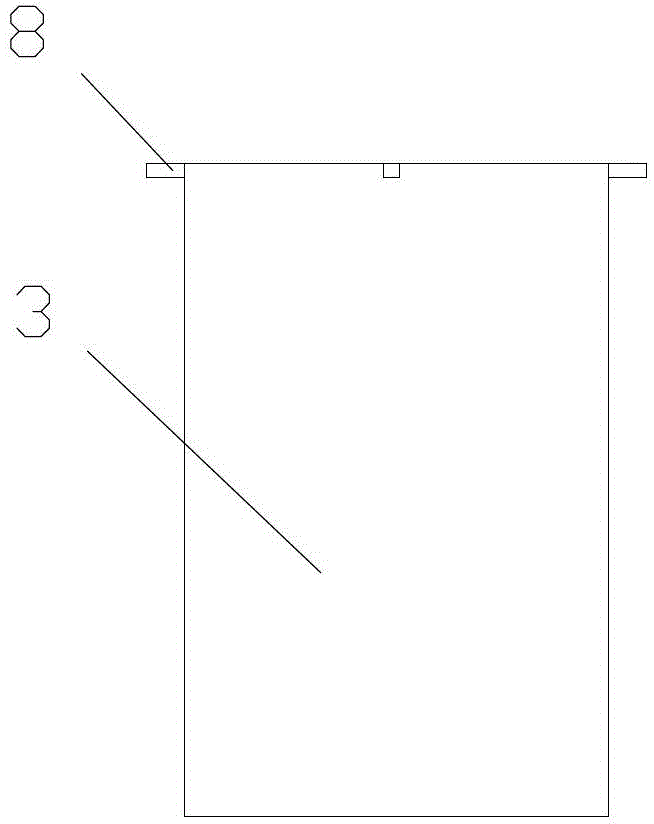

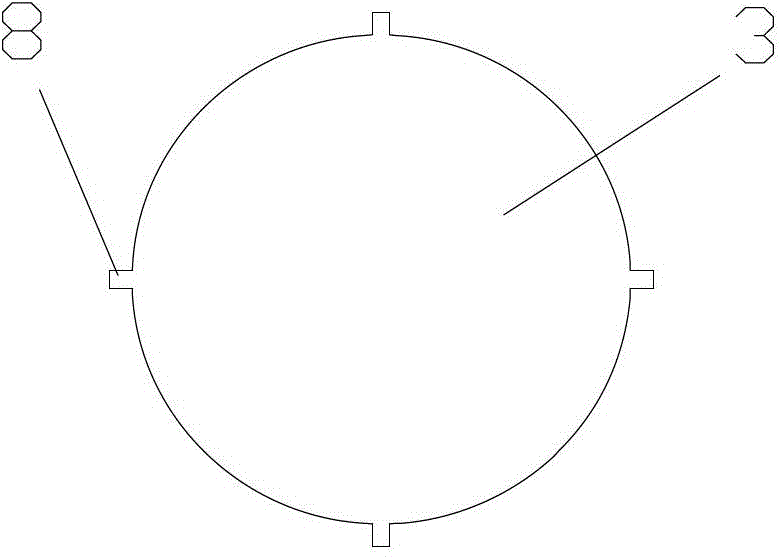

[0025] see figure 2 and image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com