Manufacturing method of elastic tatted sports underwear for women

A production method and underwear technology, applied in textiles, fabrics, corsets, etc., can solve problems such as deformation, discomfort, female breast vibration and aggravated human body, etc., to reduce stuffy feeling, improve hygroscopicity and water absorption, and reduce vibration discomfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

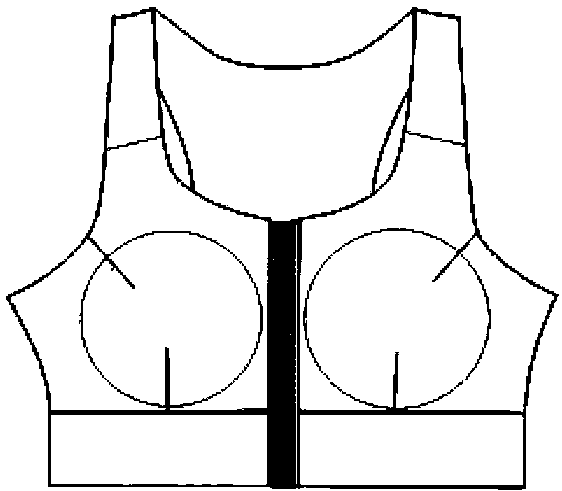

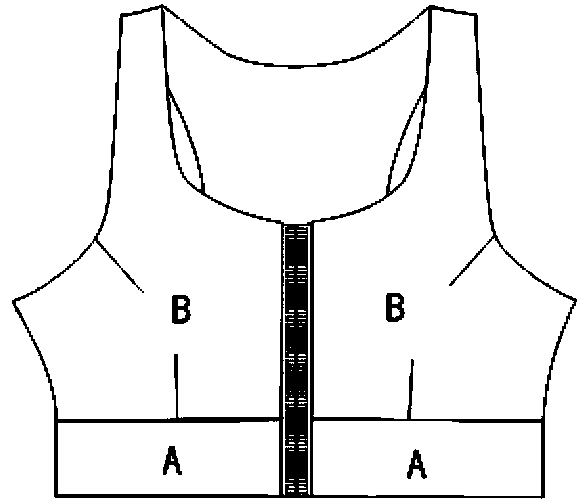

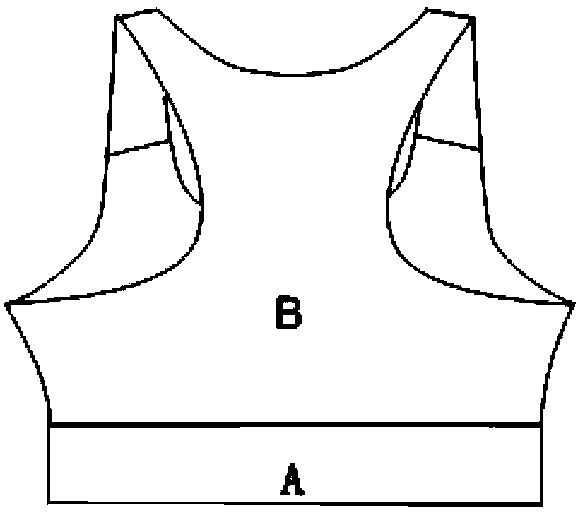

[0050] Step 1, design style structure and division of oblique cutting area

[0051] Spandex core-spun elastic cotton fabric is used as the fabric and lining of the sports underwear, and an open-end zipper is set at the center line of the front garment, and a built-in chest pad is built in the front garment; the bias cutting area is divided into: 80° general The material is used in area A, and the soft material at 50° is used in area B, where area A is the lower part of the sports underwear, and area B is the front and back parts of the sports underwear;

[0052] Step 2, plate cutting and sewing

[0053] According to the national standard woven sports underwear 160 / 84, the finished product specification table is shown in Table 1. The lower part of the sports underwear, the front garment piece and the back garment piece are drawn, cut, and dwarfed according to step 1. , Seam the edge and wait for use; then sew the fabric and lining of the front and back garments, the zipper, th...

Embodiment 2

[0057] Step 1, design style structure and division of oblique cutting area

[0058] Spandex core-spun elastic cotton fabric is used as the fabric and lining of the sports underwear, and an open-end zipper is set at the center line of the front panel, and a chest pad is built in the front panel; the bias cutting area is divided into: 70°general The material is used in area A, and the soft material at 40° is used in area B, where area A is the lower part of the sports underwear, and area B is the front and back parts of the sports underwear;

[0059] Step 2, plate cutting and sewing

[0060] According to the national standard woven sports underwear 160 / 84 finished product specification table, the lower part of the sports underwear, the front garment piece and the back garment piece are drawn, cut, dart, and seamed according to step 1 for use Then sew the fabric and lining of the front and back garments, the zipper, the front and rear panels and the lower circumference in sequen...

Embodiment 3

[0062] Step 1, design style structure and division of oblique cutting area

[0063] Spandex core-spun elastic cotton fabric is used as the fabric and lining of the sports underwear, and an open-end zipper is set at the center line of the front garment, and a built-in chest pad is built in the front garment; the bias cutting area is divided into: 90° common The material is used in area A, and the soft material at 60° is used in area B, where area A is the lower part of the sports underwear, and area B is the front and back parts of the sports underwear;

[0064] Step 2, plate cutting and sewing

[0065] According to the national standard woven sports underwear 160 / 84 finished product specification table, the lower part of the sports underwear, the front garment piece and the back garment piece are drawn, cut, dart, and seamed according to step 1 for use ; Then sew the fabric and lining of the front and back garments, the zipper, the front and rear panels and the lower circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com