Vacuum cover

A vacuum and cover technology, which is applied in the direction of drinking water containers, etc., can solve the problems of high welding quality requirements, influence on heat preservation effect, and small friction force, etc., achieve low molding process requirements, avoid poor sealing performance, and improve heat preservation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

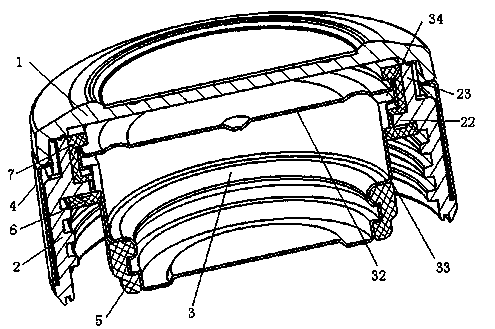

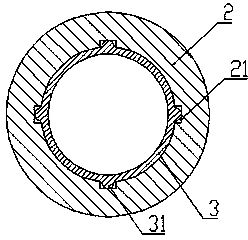

[0028] figure 1 It is a vacuum cover of the present invention, comprising a cover bottom 1, a cover body 2 fixedly connected with the cover bottom 1, the cover body 2 is made of heat insulating material, the inner side wall of the cover body 2 and the cup body The outer side wall of the cup is matched for detachable connection; and the vacuum liner 3 located inside the cover body 2 and the cover bottom 1, the vacuum liner 3 is inserted into the inner side of the cup body and is tightly connected with the cup body; The vacuum liner 3 is fixedly connected with the cover body 2 .

[0029] In the present invention, there is not only one way for the vacuum liner 3 to be fixedly connected to the cover body 2 , and methods such as threaded connection, bonding, and buckle connection can be selected. As a preference, this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com