Automobile, automobile seat and sliding rail mechanism of automobile seat

A technology for car seats and slide rails, which is applied to vehicle seats, special positions of vehicles, vehicle parts, etc., can solve the problems of difficult manufacturing, poor adaptability, and complex structure of upper slide rails, so as to reduce development and production costs. The effect of shortening the development cycle and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

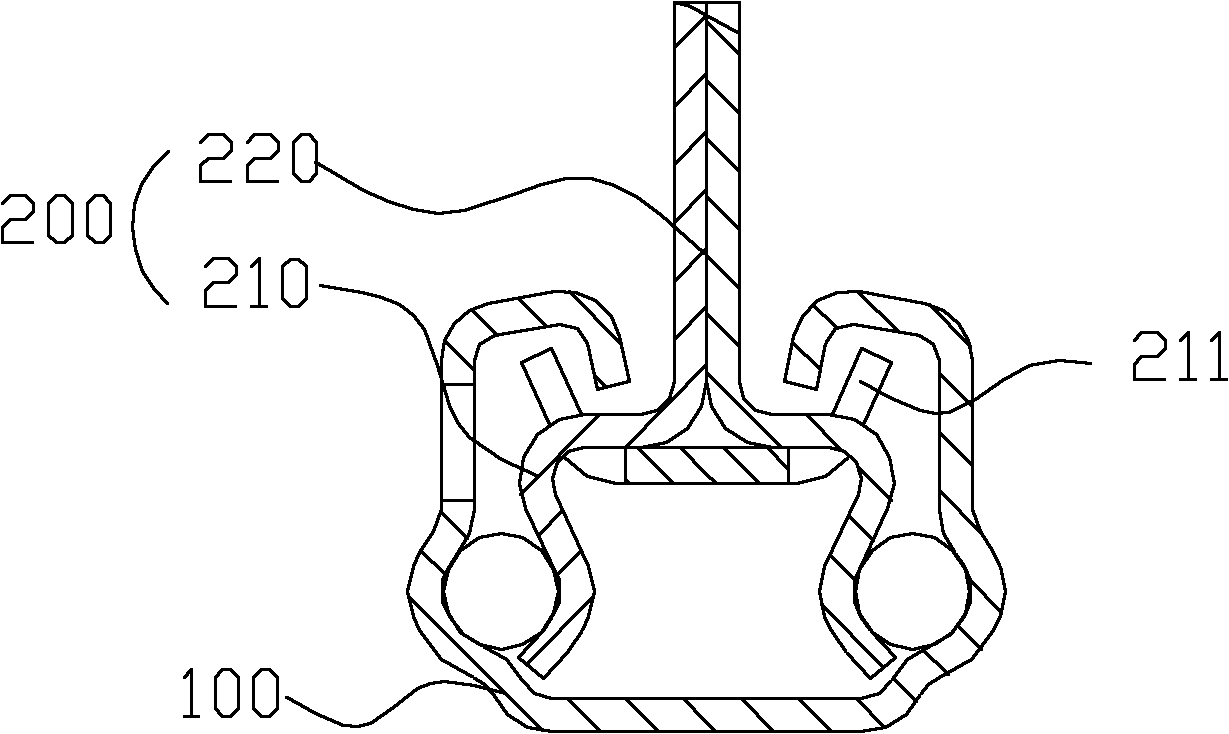

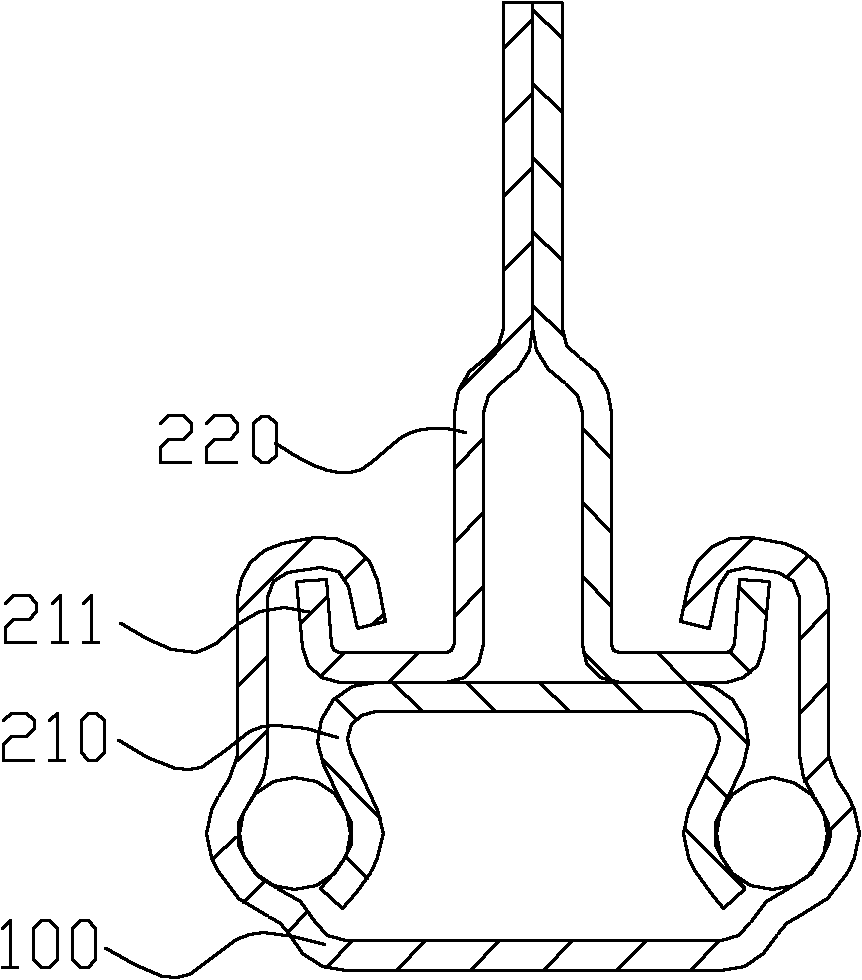

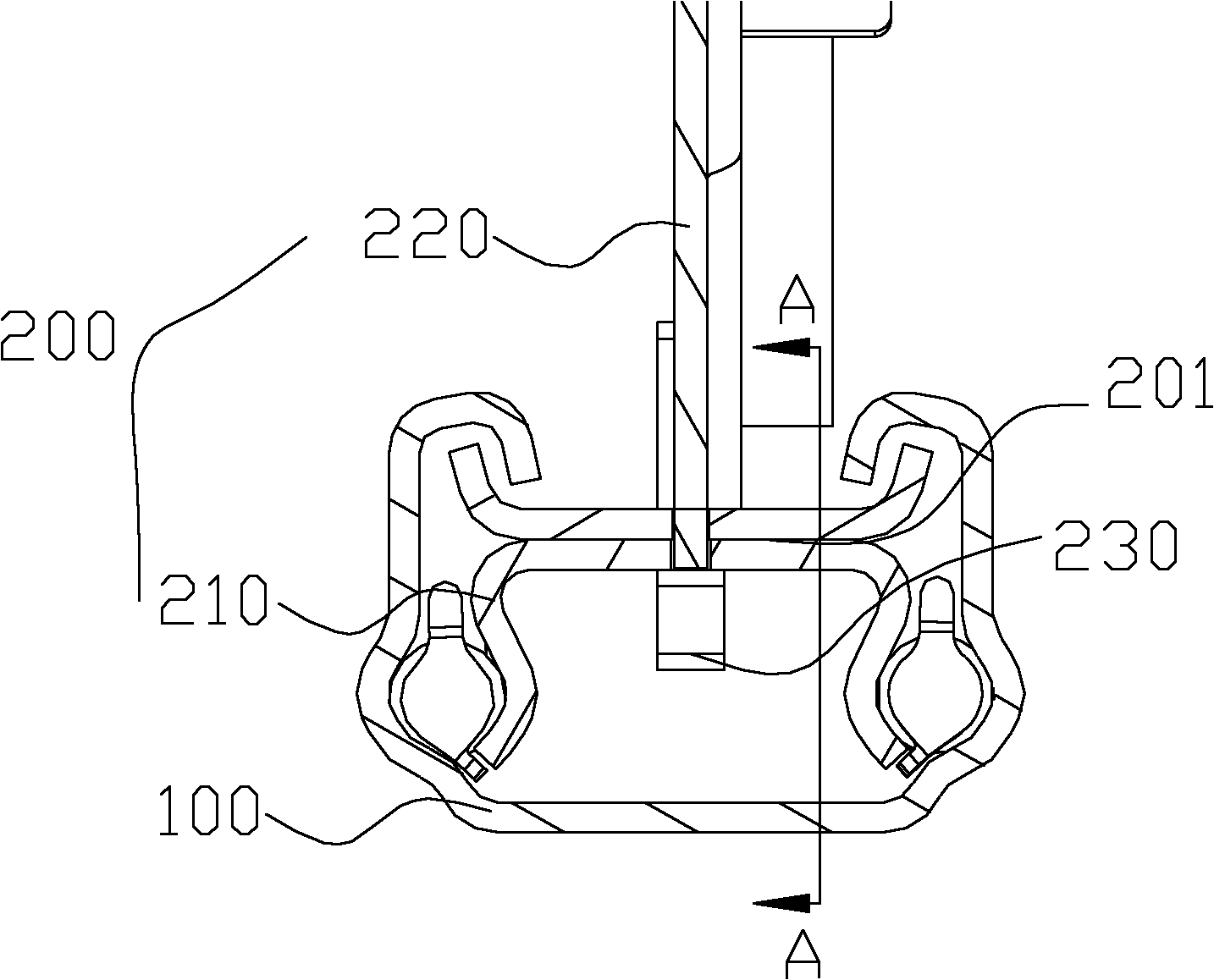

[0040]The slide rail mechanism provided in Embodiment 1 includes a lower slide rail 100 and an upper slide rail 200 . The lower rail 100 is relatively fixed to the underframe, and its structure is similar to the prior art, including a plane plate that fits on the upper surface of the underframe. Both sides of the plane plate are respectively provided with upwardly folded vertical surfaces; The lower part of the surface forms an outwardly protruding groove, and the upper part close to the vertical surface is provided with an outer flange folded inward; the inner sides of the outer flanges on both sides are respectively provided with a predetermined angle. Inside hem.

[0041] The upper sliding rail 200 includes an upper sliding body 210, and the upper sliding body 210 includes a sliding part and a reinforcing part; the sliding part has a sliding base plate, the two sides of the sliding part base plate are folded down to form a lower hem, and an inner convex is formed at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com