Automobile back longitudinal beam end plate forming die

A technology for forming molds and rear longitudinal beams, which is applied in the field of automobile rear longitudinal beam end plate forming molds, can solve the problems of high cost, unfavorable long-term development, time-consuming and labor-intensive production, etc., and achieve good manufacturing accuracy, cost reduction, and high punching efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

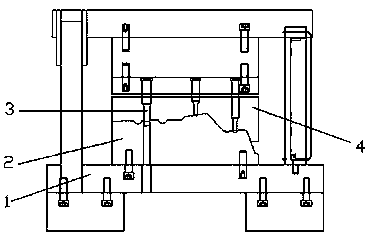

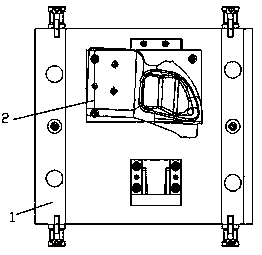

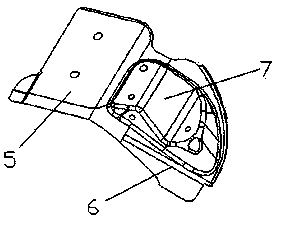

[0018] like figure 1 , figure 2 , image 3 As shown, a mold for forming the end plate of the rear longitudinal beam of an automobile includes a lower mold base, a lower mold backing plate 1, a guide post, a lower mold 2, an upper mold 4 and an upper mold fixing plate arranged sequentially from bottom to top, and the lower mold The profile surface of 2 includes a horizontal surface 5 and a curved surface 6 that are smoothly connected to each other. The horizontal surface 5 is provided with a discharge plate installation hole; the curved surface 6 is provided with a tapered protrusion 7; Pins are used to connect with the fixed plate of the upper mold; the shape of the upper mold 4 matches the shape of the lower mold 2, and the middle part is provided with a discharge rod 3; it is made of alloy steel; the upper mold 4 is provided with a guide pin; The arc of the curved su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com