Rotating shaft clamping device

A shaft clamping and collet technology, which is applied in the direction of grinding workpiece brackets, etc., can solve the problems of easy slipping and rotation of the shaft, and achieve the effects of avoiding slipping or rotation, increasing friction, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

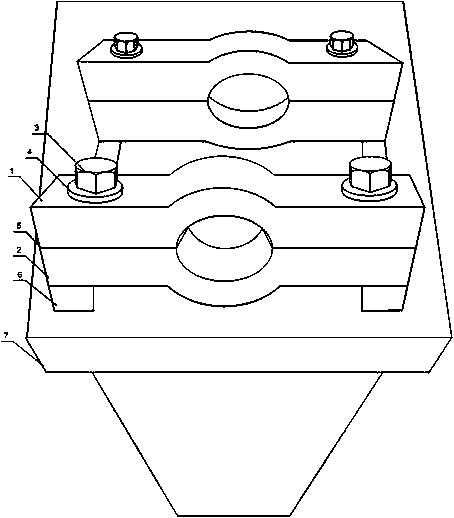

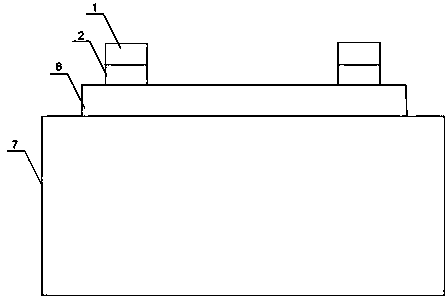

[0021] Such as figure 1 As shown, this embodiment includes a bracket 7, a slideway 6 and a fixing mechanism, the slideway 6 is installed on the bracket 7, the fixing mechanism includes an upper clamp 1 and a lower clamp 2, and the upper clamp 1 is slidably arranged on the slideway 6, the upper chuck 1 is provided with a semi-arc concave surface A, the lower chuck 2 is provided with a semi-arc concave surface B, the semi-arc concave surface A and the semi-arc concave surface B form a circular cavity, and the upper chuck 1 It is connected with the lower chuck 2 by bolts, and the inner surfaces of the semi-arc concave surface A and the semi-arc concave surface B are provided with anti-slip patterns. Adjust the bolt 3 between the upper chuck 1 and the lower chuck 2 so that the two ends of the rotating shaft are placed in the arc concave surface A, and then adjust the distance between the two by moving the two fixing mechanisms on the slide. The rotating shafts of different length...

Embodiment 2

[0024] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes an elastic gasket 5 disposed between the upper chuck 1 and the lower chuck 2 . The upper chuck 1 and the lower chuck 2 will be close to each other when they are fixed, and the force generated by the grinding machine when it contacts the rotating shaft will make the upper chuck 1, lower chuck 2 and the end of the rotating shaft collide with each other, and there will be a shock on the rotating shaft. Certain damage; the elastic gasket 5 provided can protect the end of the rotating shaft, reduce the impact force on the end of the rotating shaft, and prevent it from being damaged.

Embodiment 3

[0026] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the bottom of the lower chuck 1 is also symmetrically provided with two anti-vibration feet, which can buffer most of the force, avoid the vibration of the fixing mechanism during grinding, and ensure the smoothness of grinding. Accuracy; there is a ring gasket 4 between the bolt 3 and the upper chuck 1. Since the position of the rotating shaft needs to be adjusted from time to time during grinding, the adjustment of the bolt 3 is relatively frequent, and long-term use will damage the bolt 3. If the thread is detached or the head of the bolt 3 is separated from the screw rod, the ring gasket 4 provided can strengthen the connection between the bolt 3 and the upper chuck 1, so as to extend the service life of the bolt 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap