Looping control device of towel loom

A control device and technology for towel looms, applied in looms, textiles, textiles, and papermaking, can solve problems such as inaccurate movement, large machine vibration, and complex structure, and achieve reduced machine vibration, large range, and lower mechanism cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

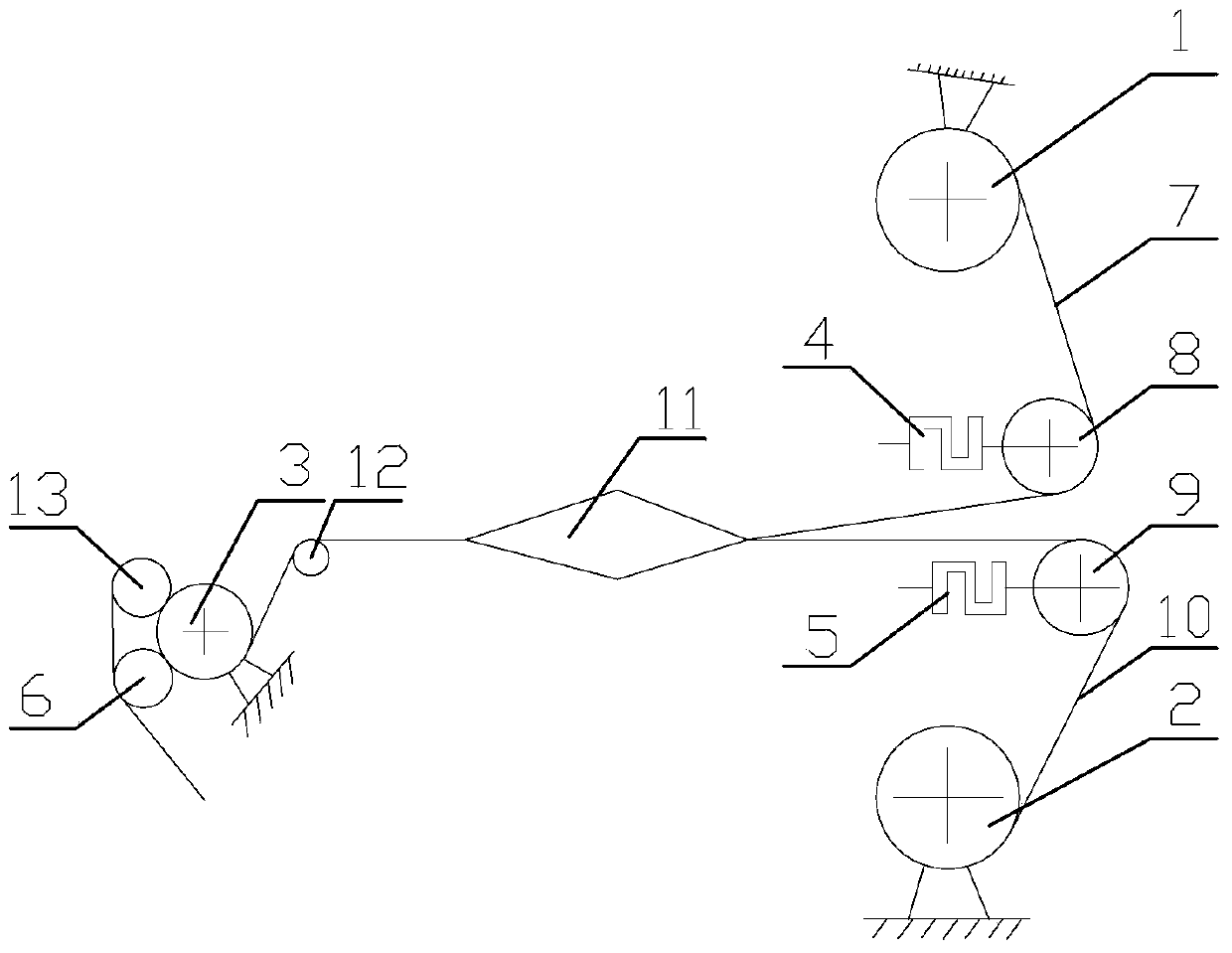

[0009] Attached below figure 1 to the attached figure 2 The present invention is further described:

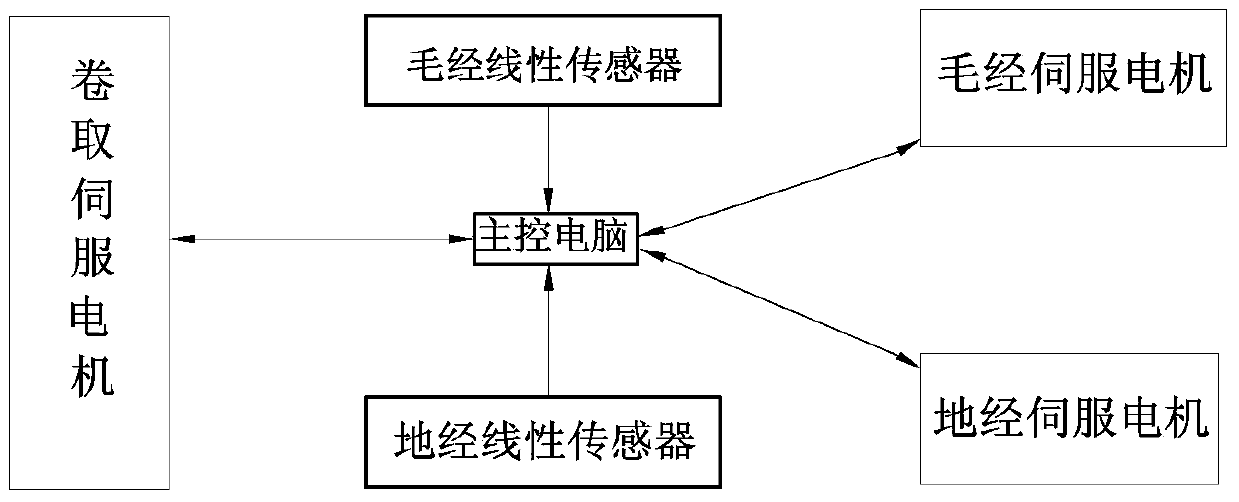

[0010] A looping control device for a towel loom, comprising a main control computer, a wool warp servo motor 1, a ground warp servo motor 2, a winding servo motor 3, a wool warp linear sensor 4 and a ground warp linear sensor 5, the wool warp servo Motor 1, ground warp servo motor 2, winding servo motor 3, wool warp linear sensor 4, and ground warp linear sensor 5 are all connected to the main control computer, and the hair warp linear sensor 4 is arranged on the back beam of the hair warp. On the mechanism 8, the ground warp linear sensor 5 is arranged on the ground warp rear beam mechanism 9, and the wool warp yarn 7 enters the opening mechanism 11, the cloth guide roller mechanism 12, and the winding servo motor in turn along the hair warp servo motor 1 and the hair warp rear beam mechanism 8. 3. Take up the upper pressure roller mechanism 13 and take off the lower pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com