Line reinforcement device for frame bridge jacking into railway branch area

A reinforcement device and frame bridge technology, which is applied to roads, paved tracks, tracks, etc., can solve problems such as weak reinforcement systems, inability to stick closely, and affect driving safety, so as to reduce maintenance and repair workload and make the swing of the point rail flexible and dense. Adhesive, to ensure the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

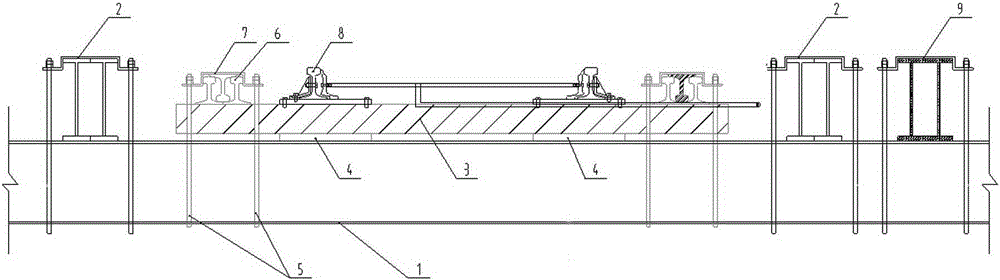

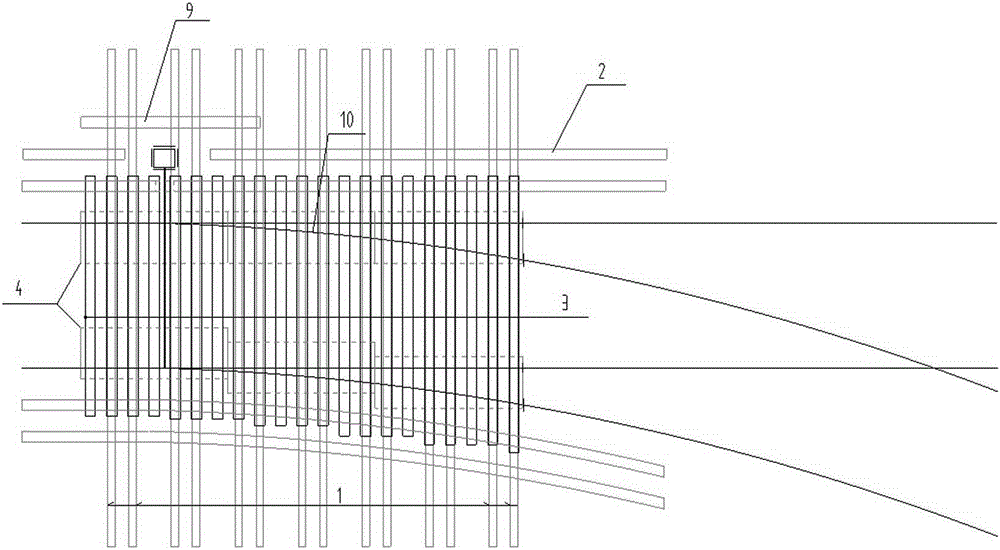

[0012] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and a specific example.

[0013] Such as figure 1 As shown in the figure, a frame bridge jacking line reinforcement device for the railway branch area includes a crossbeam 1 and a longitudinal beam 2. The crossbeam 1 is placed directly under the sleeper 3, and is placed between the crossties 1 and the crossbeam 1 directly below the switch part of the point rail in the branch area. Put longitudinal steel plate 4, crossbeam 1 and sleeper 3 are connected together by U-shaped card 5, hanging rail beam 6 and cover plate 7, and steel plate 4 is clamped between crossbeam 1 and sleeper 3.

[0014] Under the existing fork tip long sleeper 3, along the direction of the steel rail 8, two steel plates 4 with a thickness of 20 mm and a width of 500 mm are pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com