Concrete wood formwork steel buckle

A wood formwork steel buckle and concrete technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of formwork splitting, difficulty in installing or disassembling formwork, waste, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

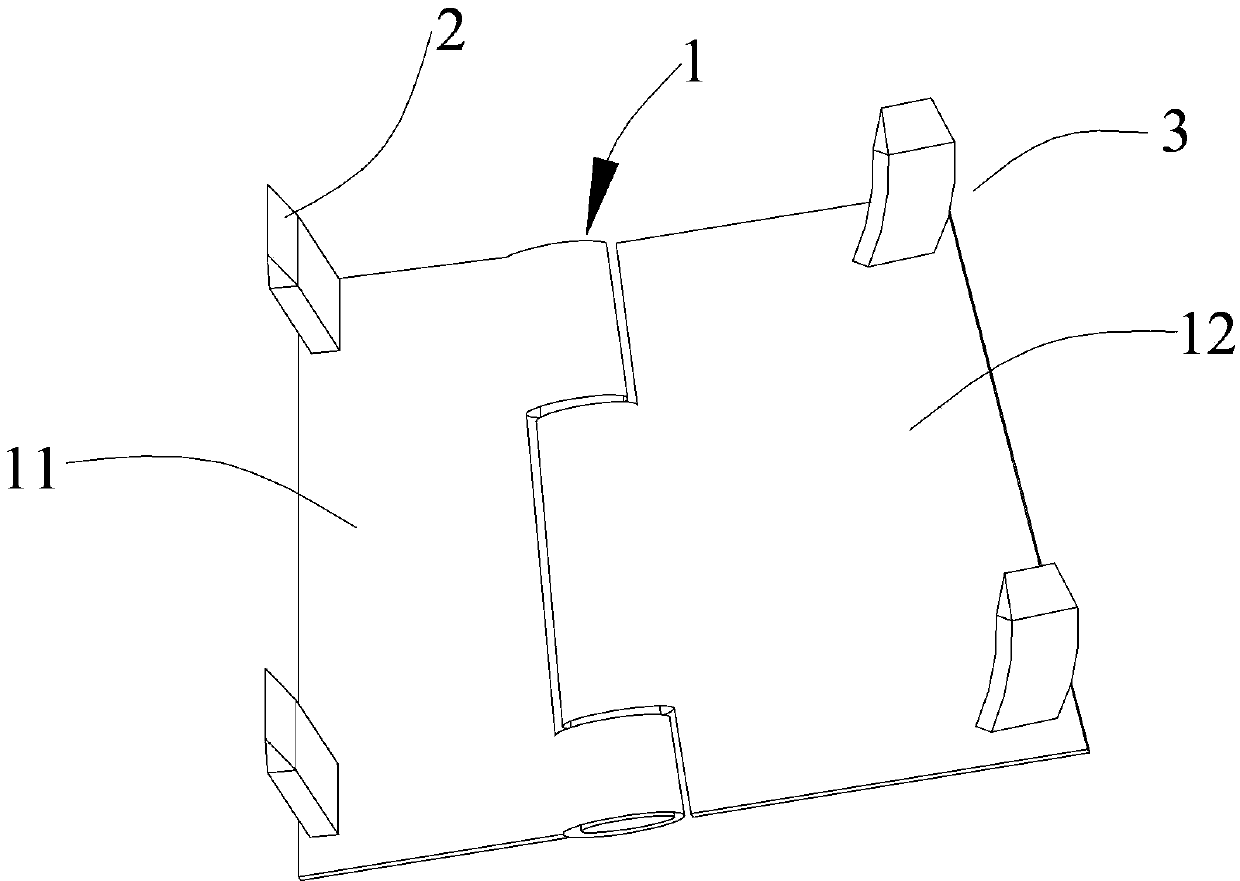

[0015] Such as figure 1 As shown, the concrete wooden mold steel buckle includes a hinge 1. The hinge 1 is composed of a left leaf 11 and a right leaf 12 hinged by pins. There is a positioning claw 2 on the two corners of the left leaf 11 away from the pins. , the positioning nail claw 2 is a straight claw, and the positioning nail claw 2 is a flat chisel shape, and there is a turning nail claw 3 on the two corners of the right sheet 12 away from the pin, and the described steering nail claw 3 is a flat chisel shape, The steering nail claw 3 is a curved claw, and the steering nail claw 3 is bent to the left, and the bending angle is 15° o .

Embodiment 2

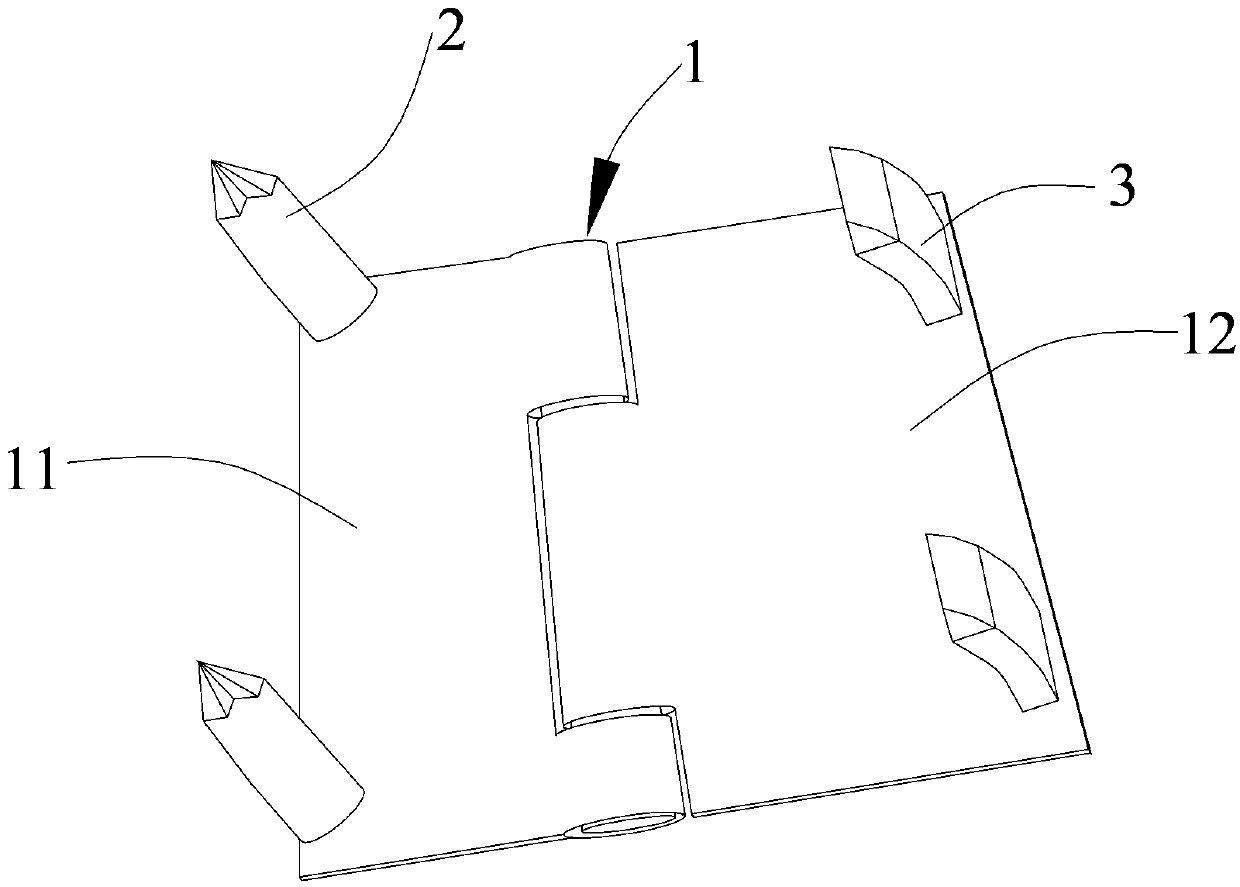

[0017] Such as figure 2 As shown, the concrete wooden mold steel buckle includes a hinge 1. The hinge 1 is composed of a left leaf 11 and a right leaf 12 hinged by pins. There is a positioning claw 2 on the two corners of the left leaf 11 away from the pins. , the positioning nail claw 2 is a straight claw, the positioning nail claw 2 is nail-shaped, and there is a steering nail claw 3 on the two corners of the right sheet 12 away from the pin, and the steering nail claw 3 is a flat chisel shape, so The steering nail claw 3 is a curved claw, and the steering nail claw 3 is bent to the left, and the bending angle is 12° o .

Embodiment 3

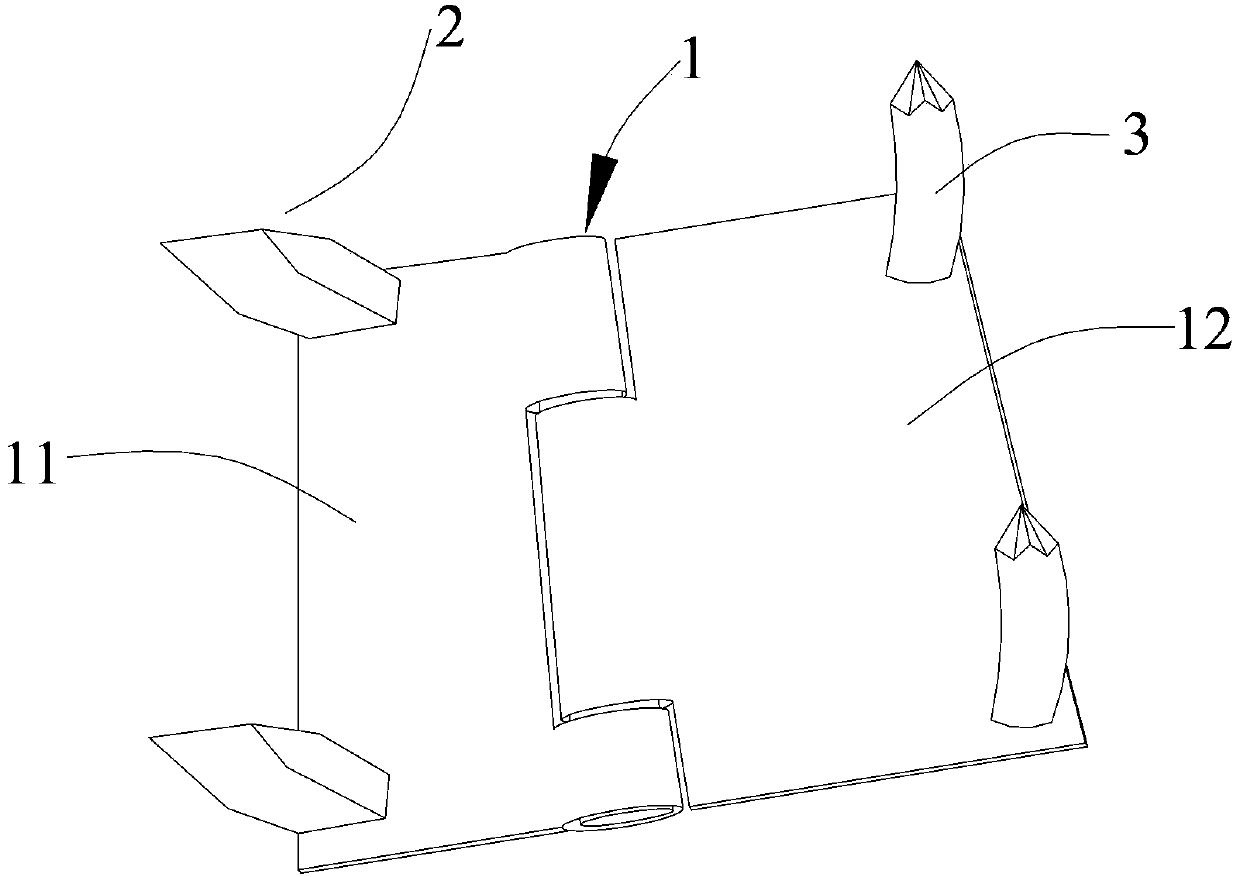

[0019] Such as image 3 As shown, the concrete wooden mold steel buckle includes a hinge 1. The hinge 1 is composed of a left leaf 11 and a right leaf 12 hinged by pins. There is a positioning claw 2 on the two corners of the left leaf 11 away from the pins. , the positioning nail claw 2 is a straight claw, and the positioning nail claw 2 is a flat chisel shape, and there is a steering nail claw 3 on the two corners of the right sheet 12 away from the pin, and the steering nail claw 3 is nail-shaped, so The steering nail claw 3 is a curved claw, and the steering nail claw 3 is bent to the left, and the bending angle is 16° o .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap