A packer structure

A technology of packer and seat seal, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of inability to achieve effective isolation, large radial design space, and small gap in the annulus of isolation To achieve the effect of ensuring the stimulation effect, improving the cementing quality and increasing the radial thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

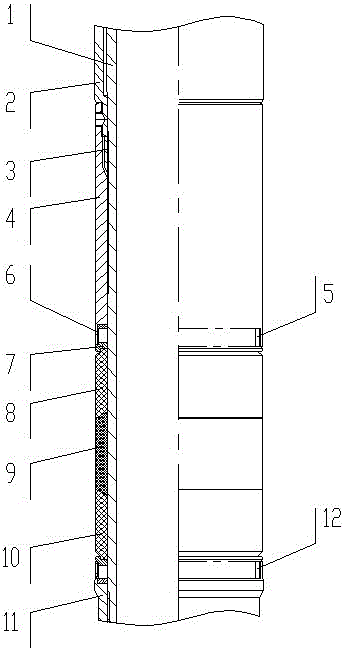

[0029] A packer structure, including a central pipe 1, a seat seal cylinder 2, a rubber cylinder seat and a rubber cylinder, the rubber cylinder seat includes an upper rubber cylinder seat 4 and a lower rubber cylinder seat 11, the seat seal cylinder 2, the upper rubber cylinder The seat 4, the rubber tube and the lower rubber tube seat 11 are set on the central tube 1 from top to bottom in sequence. A self-locking mechanism is provided between the seat sealing tube 2 and the upper rubber tube seat 4. Expansion valves are respectively provided at both ends of the rubber tube. open institutions.

[0030] The preferred implementation mode of this embodiment is that the rubber cylinder includes an upper rubber cylinder 8, a middle rubber cylinder 9 and a lower rubber cylinder 10, and the upper rubber cylinder 8, the middle rubber cylinder 9 and the lower rubber cylinder 10 are combined to form a rubber cylinder. When the cylinder 8 , the middle rubber cylinder 9 and the lower rub...

Embodiment 2

[0038] A packer structure mainly includes a center pipe 1, a seat seal cylinder 2, a rubber cartridge seat, a rubber cartridge, an end ring 7, an expansion ring, and the like. The rubber tube is placed on the lower cylindrical surface of the central tube 1, and the two ends of the rubber tube are provided with end rings 7 and expansion rings. The lower rubber tube seat 11 is connected to the lower end of the central tube 1 through threads, and the upper rubber tube seat 4 is placed on the central tube. 1. On the upper part of the rubber cylinder, the rubber cylinder seat 4 is threadedly connected with the seat seal cylinder 2, and a stop ring 3 is arranged between the seat seal cylinder 2 and the rubber cylinder seat 4.

[0039] The rubber cylinder includes an upper rubber cylinder 8, a middle rubber cylinder 9 and a lower rubber cylinder 10, and the upper rubber cylinder 8 and the middle rubber cylinder 9, the middle rubber cylinder 9 and the lower rubber cylinder 10 cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com