Air Compressor Control System

An air compressor and control system technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems that the control system cannot be adjusted in time, cannot remotely control production, and the failure rate of air compressors is high, and achieves remarkable results. , The effect of low failure rate and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

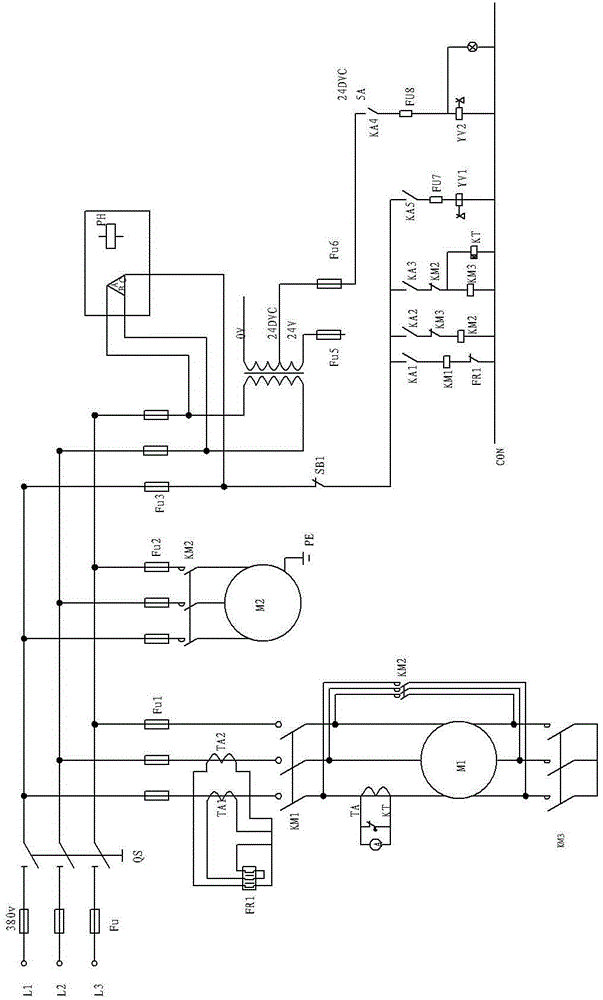

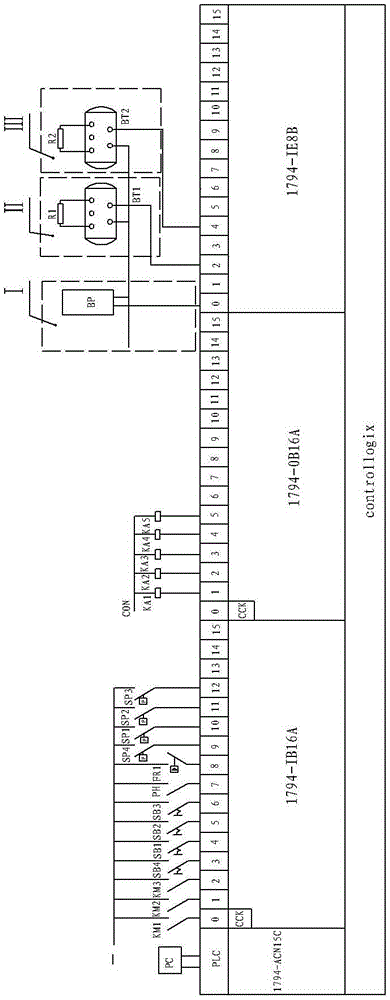

[0014] figure 1 , figure 2 The air compressor control system shown includes the main circuit part and the control circuit part. The main circuit part has the main motor M1 and the exhaust motor M2. The main motor M1 is controlled by the control circuit through the thermal relay FR1, the contactor KM1, the contactor KM2 and the The contact of contactor KM3 and the delay opening normally closed contact of time relay KT control the start and operation. The exhaust motor M2 is started and operated by the control loop through the contacts of the contactor KM2. The control circuit part includes a programmable controller connected to the backplane. The programmable controller includes a digital input module, a digital output module, an analog input module, and a control network adapter; the analog input module is connected to an exhaust pressure Control ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com