Hydraulic control device of road guardrail breakdown van

A technology for control devices and highway guardrails, which is applied to fluid pressure actuation devices, pump devices, servo meter circuits, etc., and can solve problems such as high labor intensity, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

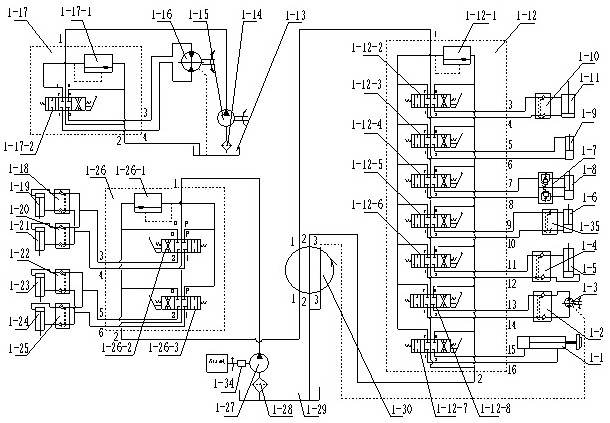

[0030] Embodiment 1: The hydraulic control device includes: rotary joint 1-30, operation controller, drilling controller, outrigger controller, oil pump assembly; the output of the oil pump assembly is to the outrigger controller, and the output of the oil pump assembly is passed through the rotary The joint 1-30 is connected to the operation controller and the drilling controller; to drive and control the operation of the pile driver.

[0031] The oil pump assembly includes: rotary joint 1-30, auxiliary oil tank 1-13, auxiliary filter screen 1-14, drilling oil pump 1-15, main oil pump 1-27, main filter screen 1-28, main oil tank 1- 29 and power take-off 1-34;

[0032] The input end of the drilling oil pump 1-15 is passed into the auxiliary oil tank 1-13 through the auxiliary filter screen 1-14, and the output end of the drilling oil pump 1-15 is connected with the No. 1 input port of the drilling control assembly valve. The No. 2 output port of the valve is connected to the ...

Embodiment 2

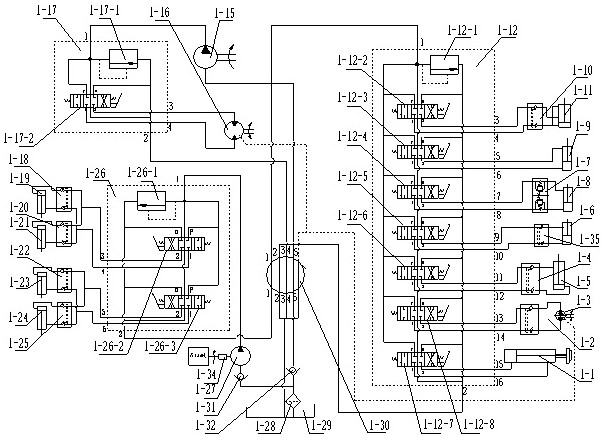

[0044] Embodiment 2: The oil pump assembly includes: rotary joint 1-30, drilling oil pump 1-15, main oil pump 1-27, main filter screen 1-28, main oil tank 1-29, main oil pump check valve 1 -31, rotary check valve 1-32 and power take-off 1-34;

[0045] The input end of the drilling oil pump 1-15 leads to the main oil tank 1-29 through the No. 4 port of the rotary joint 1-30, the rotary check valve 1-32 and the main filter screen 1-28, and the output of the drilling oil pump 1-15 The end is connected with the input port 1 of the drilling control assembly valve, and the output port 2 of the drilling control assembly valve is connected to the main oil tank 1-29 through the No. 3 port of the rotary joint 1-30; the input shaft of the main oil pump 1-27 The output shaft of the power take-off 1-34 is connected to the top, and the input gear of the power take-off 1-34 meshes with the gearbox of the automobile engine; the input end of the main oil pump 1-27 passes through the main oil p...

Embodiment 3

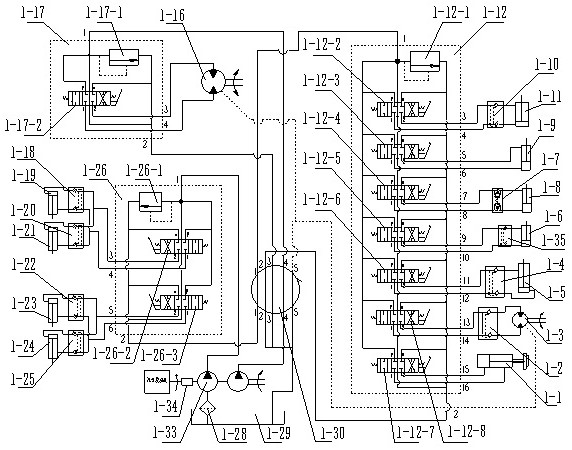

[0047] Embodiment 3: The oil pump assembly includes: a rotary joint 1-30, a main filter screen 1-28, a main oil tank 1-29, a double pump 1-33 and a power take-off 1-34;

[0048]Described duplex pump 1-33 comprises main oil pump 1-27 and borehole oil pump 1-15; Main oil pump 1-27 and borehole oil pump 1-15 are connected in series as a whole; The main filter screen 1-28 leads to the main oil tank 1-29; the output end of the drilling oil pump 1-15 of the double pump 1-33 passes through the No. 4 input and output port of the rotary joint 1-30 and the drilling control assembly valve The input port 1 is connected, and the output port 2 of the drilling control assembly valve is connected to the main oil tank 1-29 through the No. 3 port of the rotary joint 1-30; the input shaft of the main oil pump 1-27 of the double pump 1-33 is connected with The output shaft of the power take-off 1-34, the input gear of the power take-off 1-34 meshes with the gearbox of the automobile engine; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com