Tunnel section outline measuring method and device based on vision measurement

A visual measurement and tunneling technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as slow measurement speed, missed measurement of deformed defect areas, incomplete section profile information, etc., and achieves high smoothness and high sampling density. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

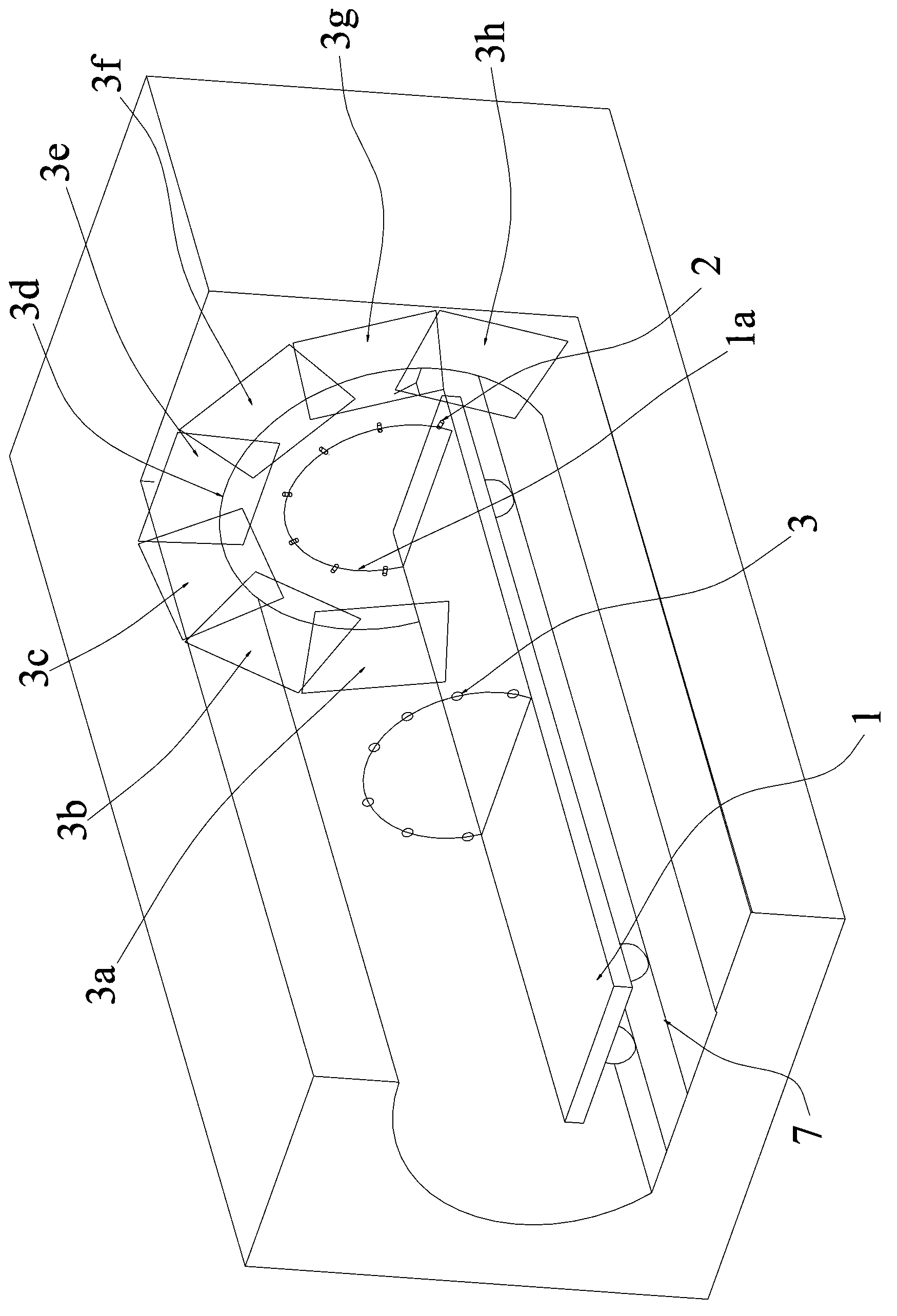

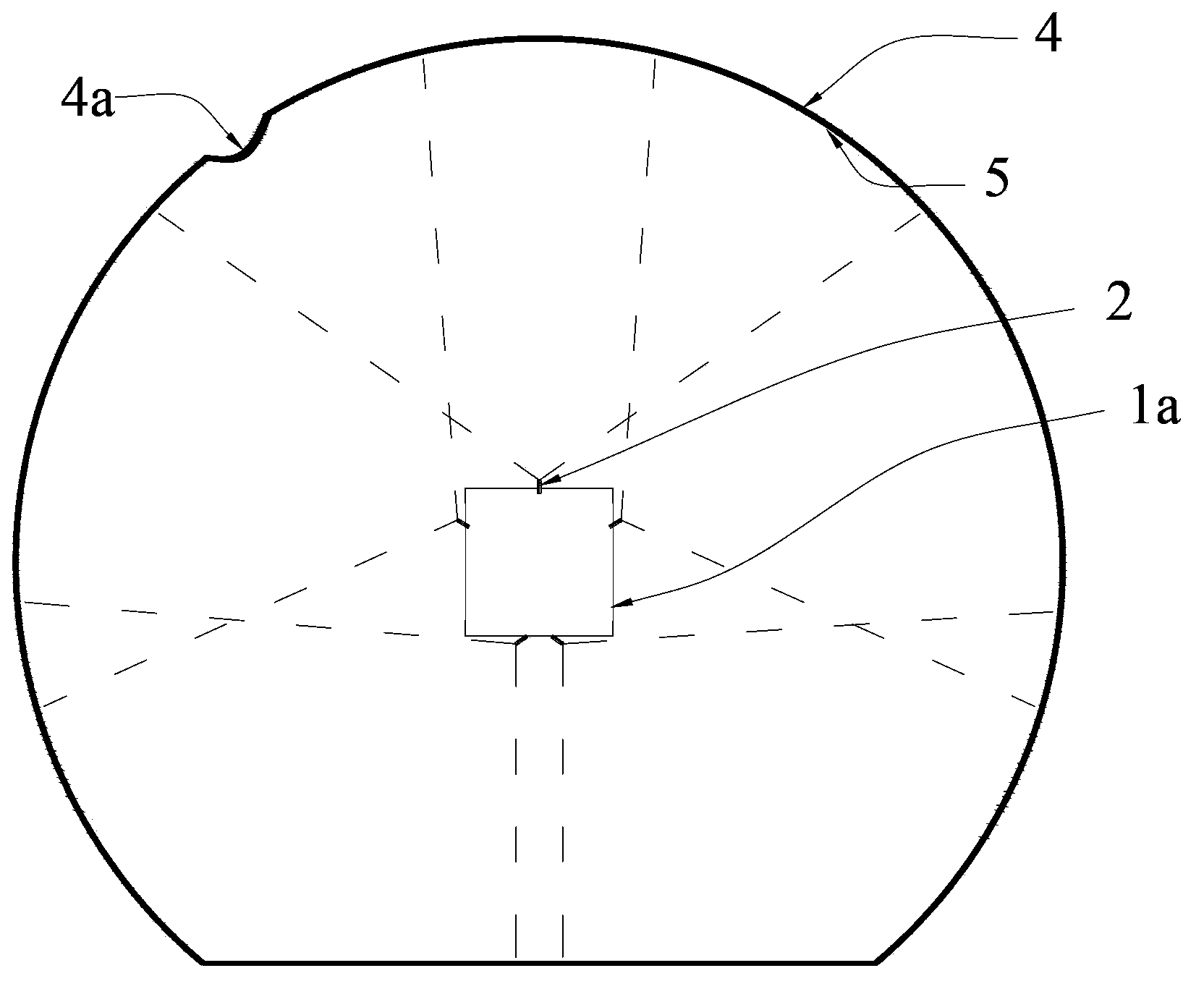

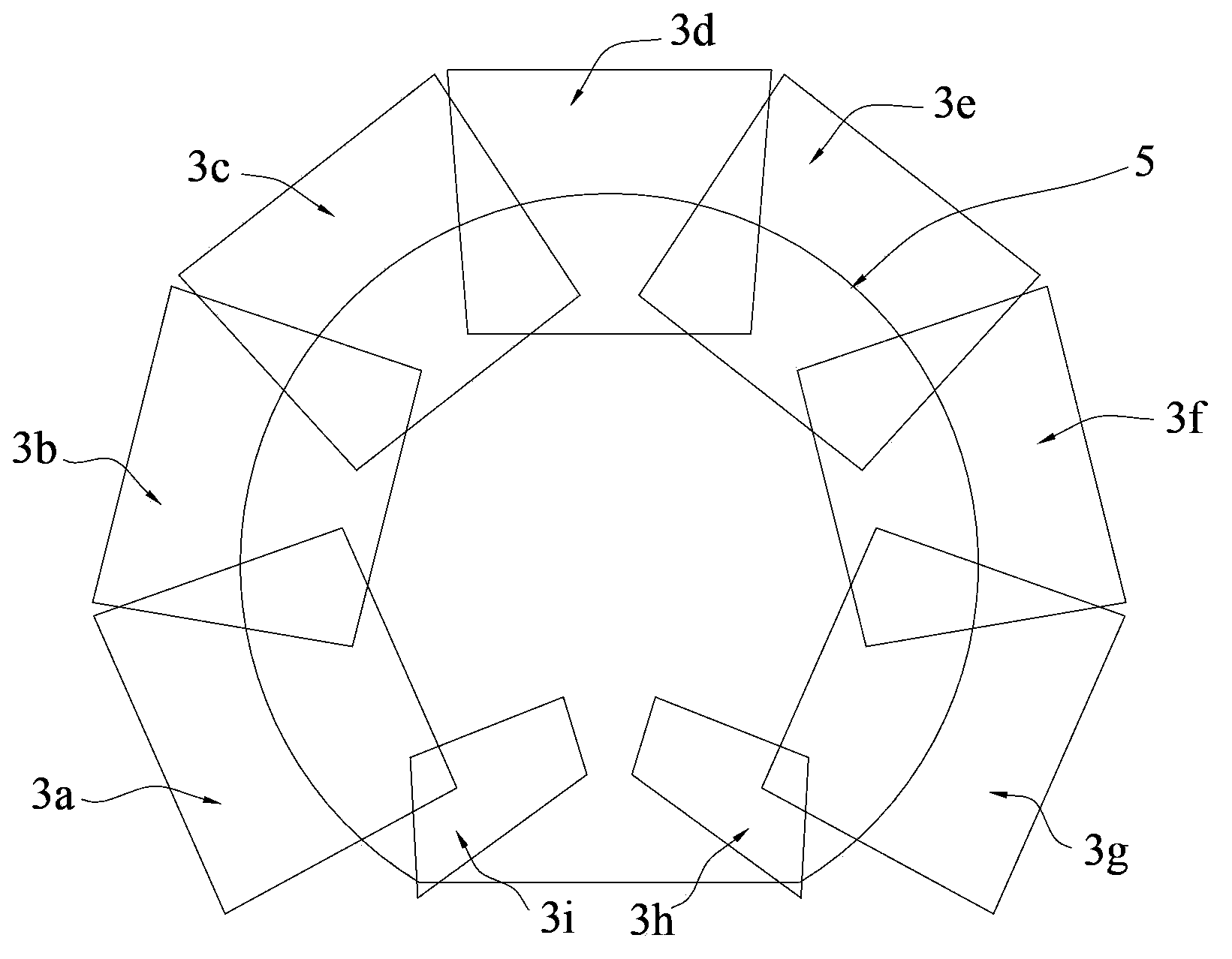

[0039] Such as Figures 1 to 3As shown, the tunnel profile measurement device based on vision measurement of the present invention includes a processor (not shown in the figure), a photoelectric encoder (not shown in the figure), a measuring vehicle 1, a structured light source and several graphic sensors 3; Wherein, the structured light source and the plurality of graphic sensors 3 are installed on the measuring vehicle 1 respectively, and the viewing ranges of several graphic sensors 3 together form a ring-like viewing range, and the viewing ranges of two adjacent graphic sensors 3 partially overlap ,Such as image 3 In the area composed of the viewing range 3a-3i, the structured light source and the several image sensors 3 need to meet the following positional relationship when installed, that is, when the measuring vehicle 1 is parked in the tunnel under test, the planar structured light emitted by the structured light source Orthogonal or nearly orthogonal to the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com