Pure electric vehicle power battery pack capacity calibration method based on current

A technology for power battery packs and pure electric vehicles, which is applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of inconvenient travel, easy to mislead drivers, etc., and achieve the effect of convenient travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

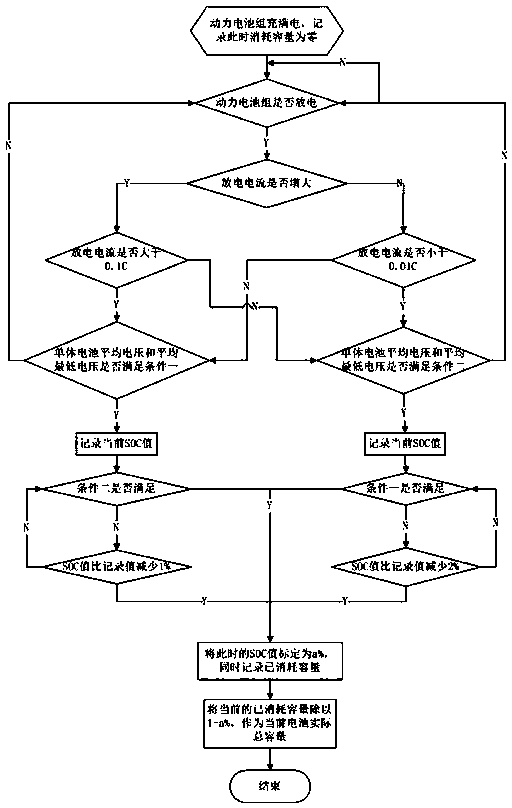

[0029] Embodiment 1: A method for calibrating the capacity of a power battery pack of a pure electric vehicle based on current, comprising the steps in the following order:

[0030] (1) When the power battery pack is fully charged, the battery management system BMS will clear the consumed capacity of the power battery pack, and then discharge the power battery pack from the full state;

[0031] (2) The battery management system BMS judges whether the current discharge current is a large current or a small current. If it is a large current, perform step (3); if it is a small current, perform step (4); the high current refers to the increase of the discharge current And the discharge rate is greater than 0.1C, or the discharge current decreases and the discharge rate is greater than or equal to 0.01C; the small current refers to the discharge current decreases and the discharge rate is less than 0.01C, or the discharge current increases and the discharge rate is less than or equa...

Embodiment 2

[0041] Embodiment 2: A method for calibrating the capacity of a power battery pack of a pure electric vehicle based on current, comprising the steps in the following order:

[0042] (1) When the power battery pack is fully charged, the battery management system BMS will clear the consumed capacity of the power battery pack, and then discharge the power battery pack from the full state;

[0043] (2) The battery management system BMS judges whether the current discharge current is a large current or a small current. If it is a large current, perform step (3); if it is a small current, perform step (4); the high current refers to the increase of the discharge current And the discharge rate is greater than 0.1C, or the discharge current decreases and the discharge rate is greater than or equal to 0.01C; the small current refers to the discharge current decreases and the discharge rate is less than 0.01C, or the discharge current increases and the discharge rate is less than or equal ...

Embodiment 3

[0052] Embodiment 3: A method for calibrating the capacity of a power battery pack of a pure electric vehicle based on current, comprising the steps in the following sequence:

[0053] (1) When the power battery pack is fully charged, the battery management system BMS will clear the consumed capacity of the power battery pack, and then discharge the power battery pack from the full state;

[0054] (2) The battery management system BMS judges whether the current discharge current is a large current or a small current. If it is a large current, perform step (3); if it is a small current, perform step (4); the high current refers to the increase of the discharge current And the discharge rate is greater than 0.1C, or the discharge current decreases and the discharge rate is greater than or equal to 0.01C; the small current refers to the discharge current decreases and the discharge rate is less than 0.01C, or the discharge current increases and the discharge rate is less than or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com