BP (Back Propagation) neural network-based exhaust dryness computing method of USC (Ultra-Supercritical) turbine

A BP neural network, ultra-supercritical technology, applied in the direction of biological neural network model, calculation, instrument, etc., can solve the problems of complex process, unsuitable, low measurement method accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

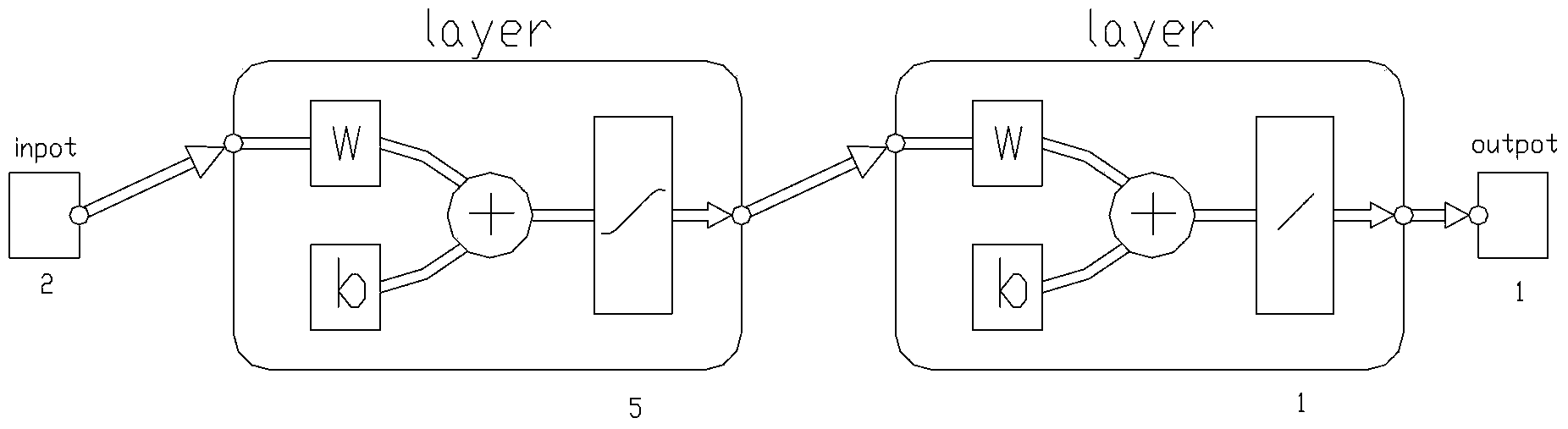

[0047] The embodiment of the method for calculating the dryness degree of ultra-supercritical steam turbine exhaust based on the BP neural network of the present invention includes the following steps: S1. Part of the formula of the BP neural network algorithm

[0048] (1) BP network forward propagation calculation

[0049] net ij = Σ k = 1 N i - 1 O ( i - 1 ) k W ( i - 1 ) kj

[0050] O ij = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com