Rolled Copper Foil

A technology of rolling copper foil and copper foil, which is applied in the field of rolling copper foil, can solve the problems of reduced yield and reduced circuit etching, and achieve the effects of excellent bendability, improved operability, and good etching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

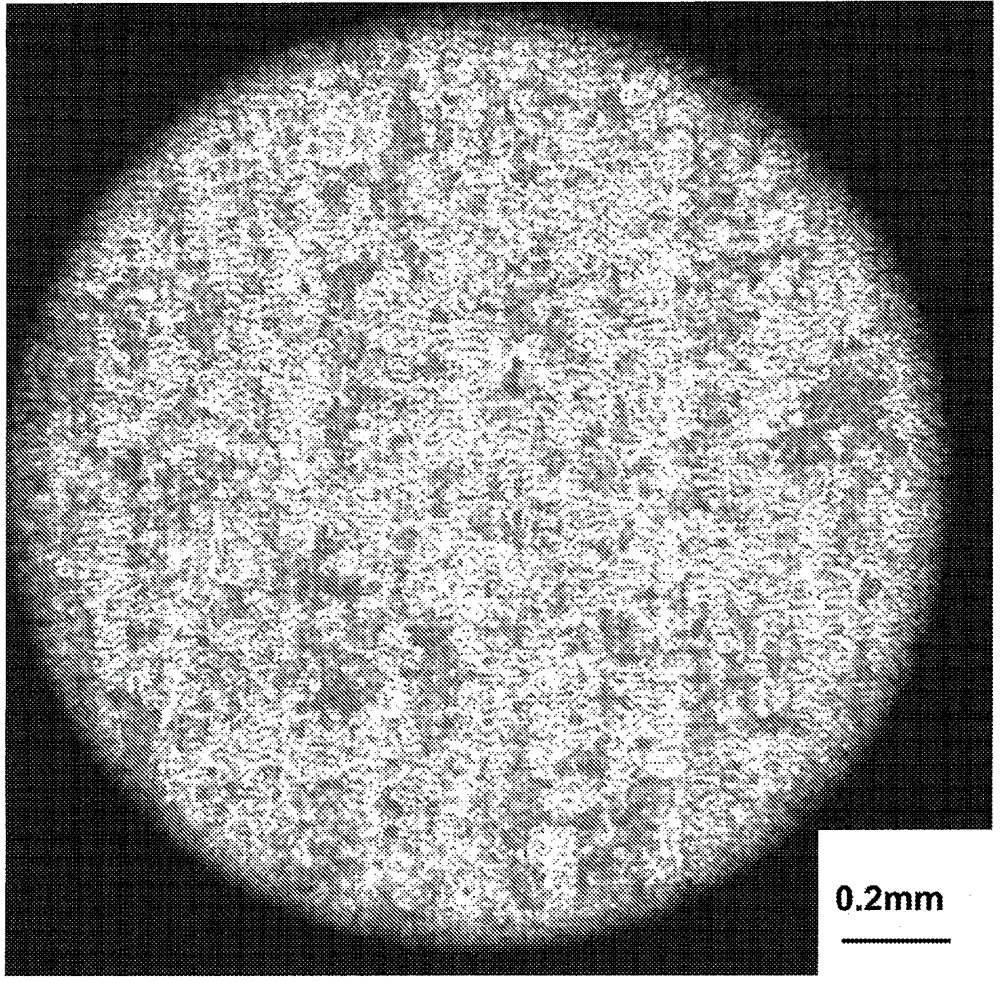

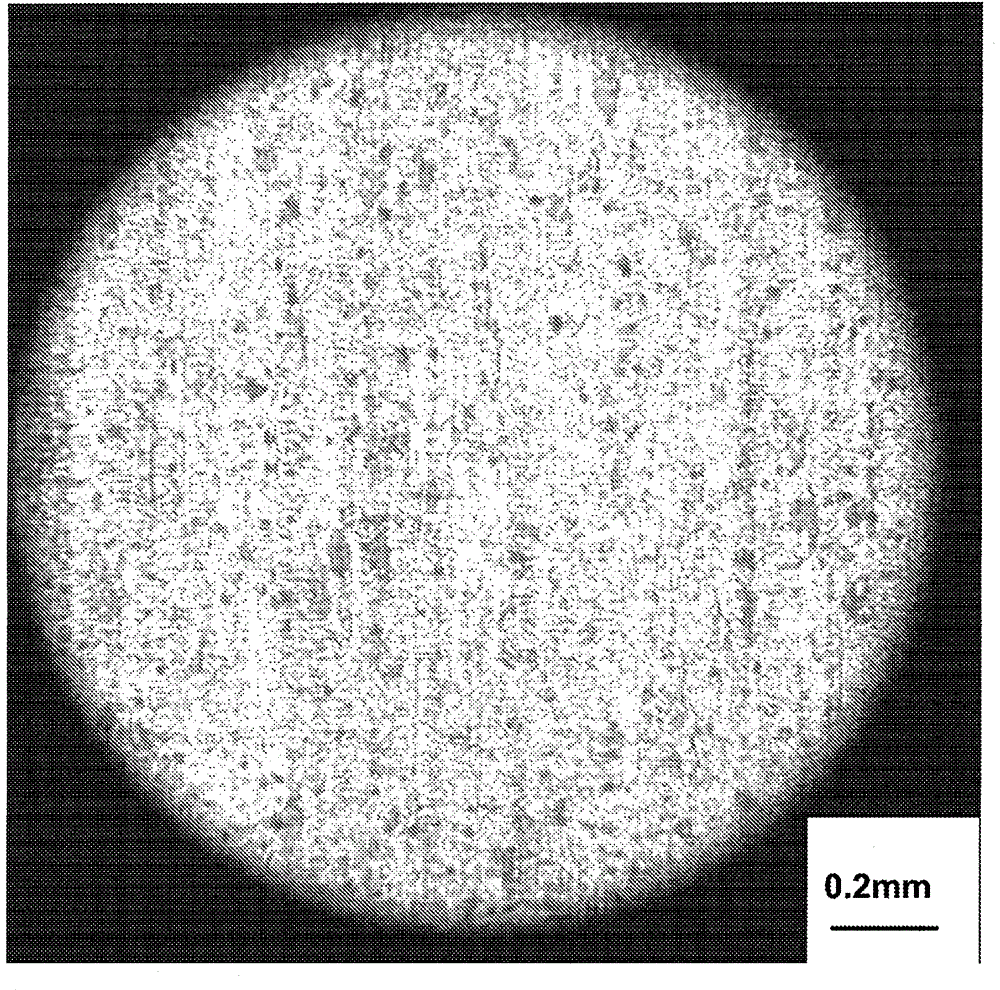

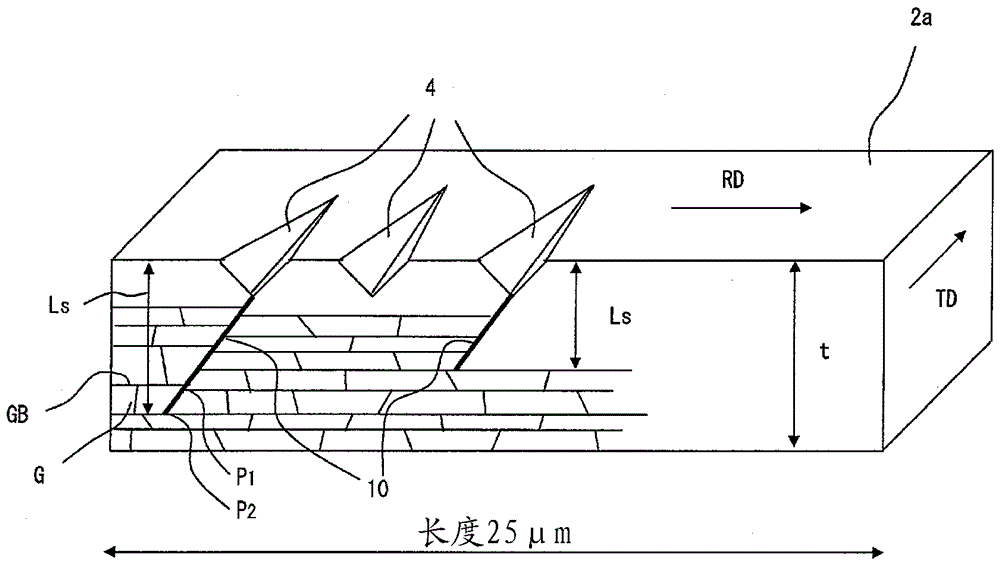

[0088] The copper or copper alloy with the composition shown in Table 1 is used as a raw material to cast ingots, and hot rolled at above 800°C until the thickness reaches 10mm. Finishing during rolling to a thickness of 0.009-0.018mm. The rolling processing degree in the final cold rolling is 95 to 99.8%. In addition, in Table 1, tough copper is described as TPC, and oxygen-free copper is described as OFC. Oxygen-free copper is oxygen-free copper specified in JIS-H0500 (C1011), and ductile copper is tough copper specified in JIS-H0500 (C1100).

[0089] The final cold rolling was performed in 10 to 15 passes, and as shown in Table 1, the rolling was performed while changing the surface roughness of the rolls up to the final pass and the surface roughness of the rolls in the final pass. The surface roughness of the rolls from the first pass of final rolling to before the final pass was completely the same.

[0090] In addition, as "Reference Examples 6-9", according to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com