Ultrasonic magnetic composite grinding device and grinding process for jade relief crafts

A grinding device and a grinding process technology are applied in the field of stone processing to achieve the effects of improving processing efficiency and processing quality, making up for defects in manual polishing, and uniform surface polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

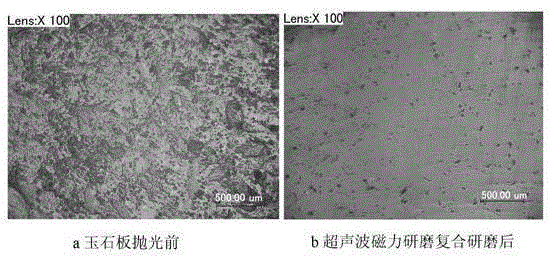

[0035] Embodiment 1: Polishing the surface of a 100×50×10mm jade slab.

[0036] Auxiliary materials: sintered magnetic abrasive, water-based grinding liquid, diamond grinding paste, iron powder, cleaning agent.

[0037] ① Cleaning: First, use an ultrasonic cleaning machine to add a small amount of cleaning agent to clean the surface of the jade slab, remove the surface stains of the jade relief crafts, and dry it;

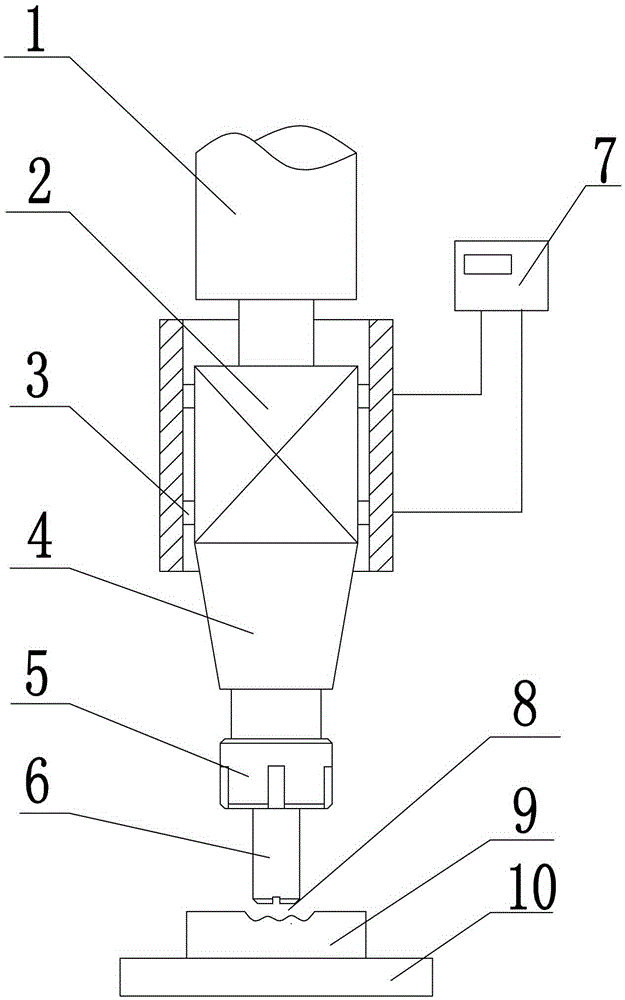

[0038] ②Clamping: Fix the jade plate to be processed on the fixed workpiece table 10 of the numerical control auxiliary frame of the ultrasonic magnetic composite grinding device. The fixed workpiece table 10 is a magnetic material, which can be formed with the permanent magnet 6 after magnetization closed magnetic circuit;

[0039] ③Parameter setting: start the ultrasonic generator 7, set the frequency of ultrasonic generation to 15-20KHz, and the amplitude to 10-20μm;

[0040] ④ Coarse throwing: Mix the sintered magnetic abrasive with a particle size of 250-350...

Embodiment 2

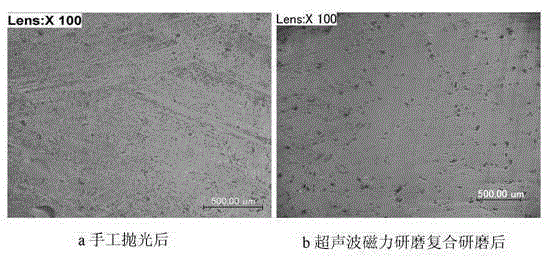

[0046] Embodiment two: to the surface polishing of Buddha statue jade carving handicraft.

[0047] Auxiliary materials: sintered magnetic abrasive, water-based grinding liquid, diamond grinding paste, iron powder, cleaning agent.

[0048] ① Cleaning: First, use an ultrasonic cleaning machine to add a small amount of cleaning agent to clean the surface of the Buddha statue jade carving handicraft, remove the surface stains of the Buddha statue jade carving handicraft, and dry it;

[0049] ②Clamping: Install the Buddha statue and jade carving handicraft to be processed on the fixed workpiece workbench 10 of the numerical control auxiliary frame of the ultrasonic magnetic composite grinding device. 6 to form a closed magnetic circuit;

[0050] ③Parameter setting: start the ultrasonic generator 7, set the frequency of ultrasonic generation to 15-20KHz, and the amplitude to 10-20μm;

[0051] ④ Coarse throwing: Mix the sintered magnetic abrasive with a particle size of 200-250 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com