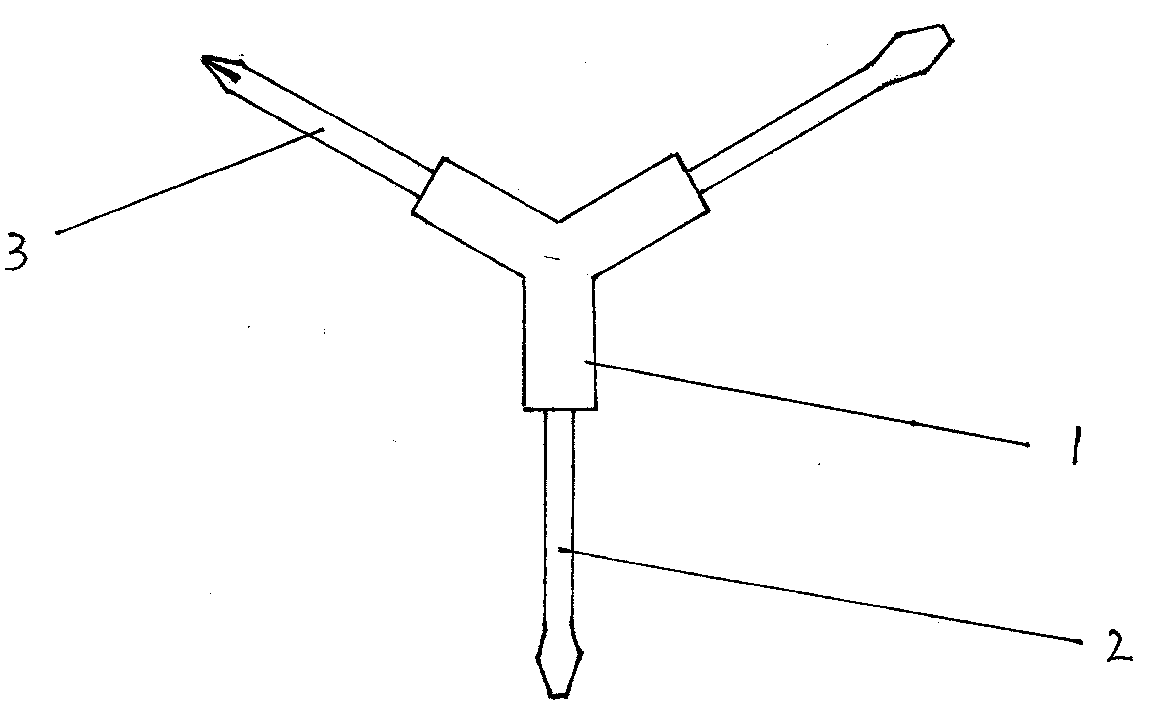

Dual-purpose screw driver with Y-shaped handle

A screwdriver, dual-purpose technology, applied in screwdrivers, manufacturing tools, etc., can solve the problems of easy damage and low torque, and achieve the effects of low manufacturing cost, large torque and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] exist figure 1 In the shown embodiment, a screwdriver handle (1) is provided with plastic material, and the screwdriver handle (1) has a three-fork shape with three cylindrical ends, and the tails of the three cylindrical ends are connected together, which is a As a whole, the angle between the axes of the three cylindrical ends is 120°; two flat screwdriver rods (2) and one cross screwdriver rod (3) are respectively set up by metal materials, and the tails of the three screwdriver rods are respectively cast on three inside a cylindrical end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com