The method for preparing ginkgolide B by using the thallus thale as a catalyst

A kind of rhizoma rhizogenes and ginkgolide technology, applied in the field of bioengineering, can solve problems such as difficulty in mass production and ginkgolide production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

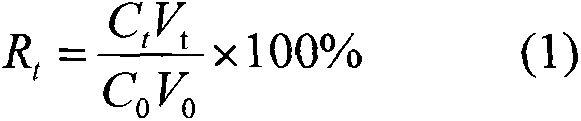

Method used

Image

Examples

Embodiment 1

[0017] Preparation of Test Tube Strains

[0018] Preparation of Potato Dextrose Agar Medium: Weigh 200g of potatoes, cut them into slices, add 1000mL of water, boil for 30 minutes, filter, dilute the filtrate to 1000mL, add 20g of agar, heat until the agar is completely melted, and pack into 18×200mm test tubes, 15mL medium per tube, sterilized at 120°C for 30 minutes, cooled to 50°C, placed on an inclined plane, the length of the inclined plane was half the length of the test tube; Cut the strain into 4×4mm small pieces, pick a small piece and transfer it to a test tube containing potato dextrose agar medium, culture it at 20°C for 20 days to obtain the strain on the slant of the test tube, and store the slant of the test tube at 4°C for later use;

[0019] Preparation of Fermentation Broth Containing Ginkgolide B

[0020] 1. Preparation of strains in liquid shake flasks

[0021] The formula of liquid shake flask culture medium is (unit is g / L) glucose 5, corn flour 5, pept...

Embodiment 4

[0037] Embodiment 4 contains the preparation of the fermented liquid of ginkgolide B

[0038] 1. Production of strains in shake flasks

[0039] The formula of shake flask culture medium is (unit is g / L): glucose 40, corn flour 25, peptone 10, KH 2 PO 4 6. MgSO 4 4. The initial pH value is 8.0. A total of 2000mL was prepared, divided into 250mL Erlenmeyer flasks (10 bottles in total), 150mL per bottle, and sterilized at 140°C for 20 minutes. After cooling, cut the slant strains of the test tube of Basidiomyces pilosa isolated from the fruiting body of Auricularia tibetanus into small pieces of 4×4mm in size, pick 4 pieces and transfer them to the Erlenmeyer flask containing the shake flask culture medium , placed on a shaker at 30°C and 150 rpm for 46 hours.

[0040] 2. Preparation of seed tank strains

[0041] The 50L seed tank is filled with 30L seed culture medium, and the formula of the seed tank culture medium is (unit is g / L): glucose 40, corn flour 25, peptone 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com