Febuxotat microcrystal and compositions thereof

A composition and microcrystalline technology, which is applied in the direction of drug combination, organic active ingredients, bone diseases, etc., can solve the problems of low solubility of febutadate and poor dissolution rate of oral solid preparations, etc., and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

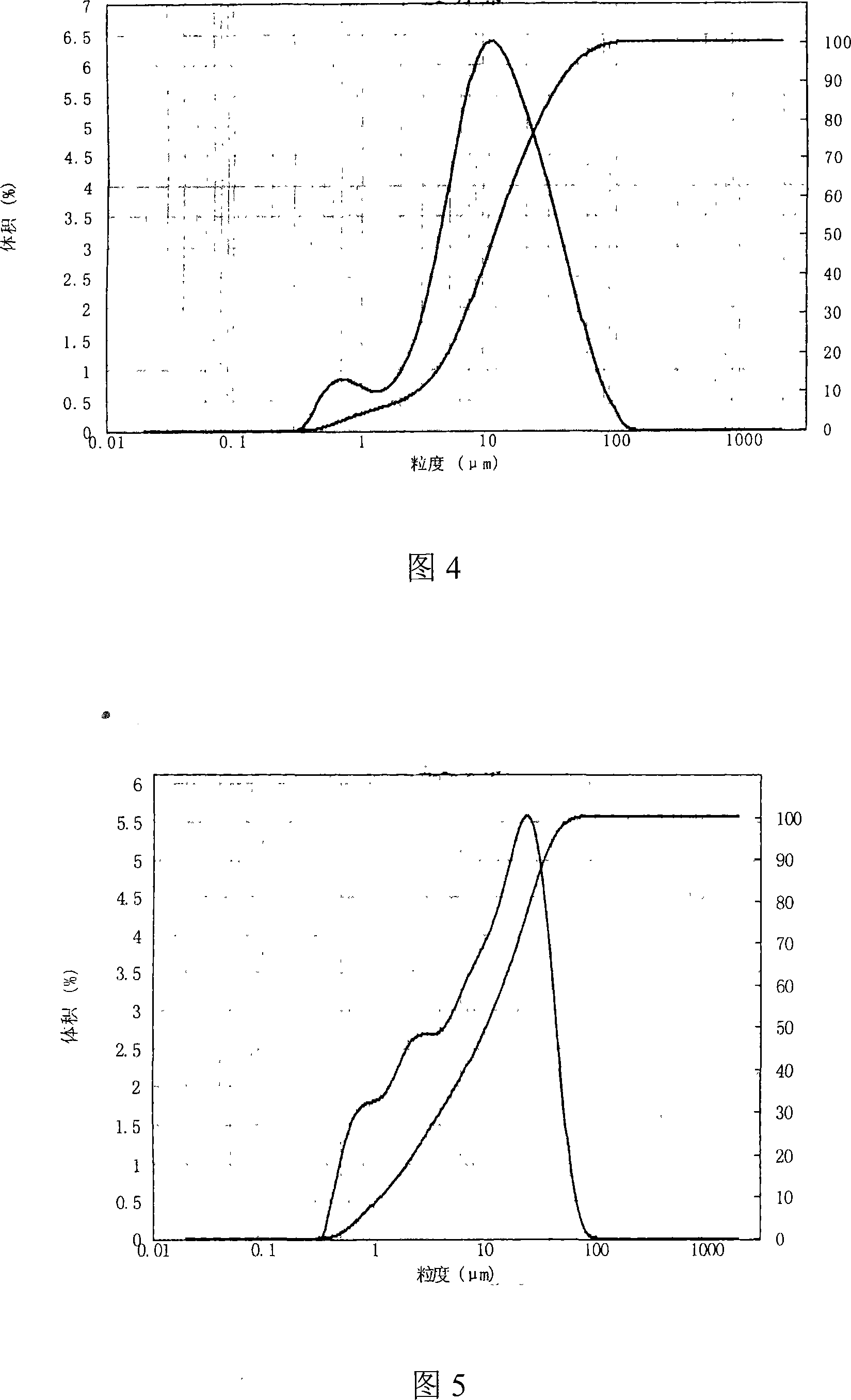

[0021] Add 100g of febutadate crude product and 1400ml of ethyl acetate into a 3L round-bottomed flask, raise the temperature to reflux, stir until it is completely dissolved, then filter while it is hot, leave the filtrate to cool down to room temperature naturally, crystallize, filter, and filter the cake with a small amount of Washed with ethyl acetate, dried in vacuum at 80°C for 4 hours to obtain 82.6 g of solid, mp 198.7-201.4°C (determined by differential thermal analysis, see Figure 3).

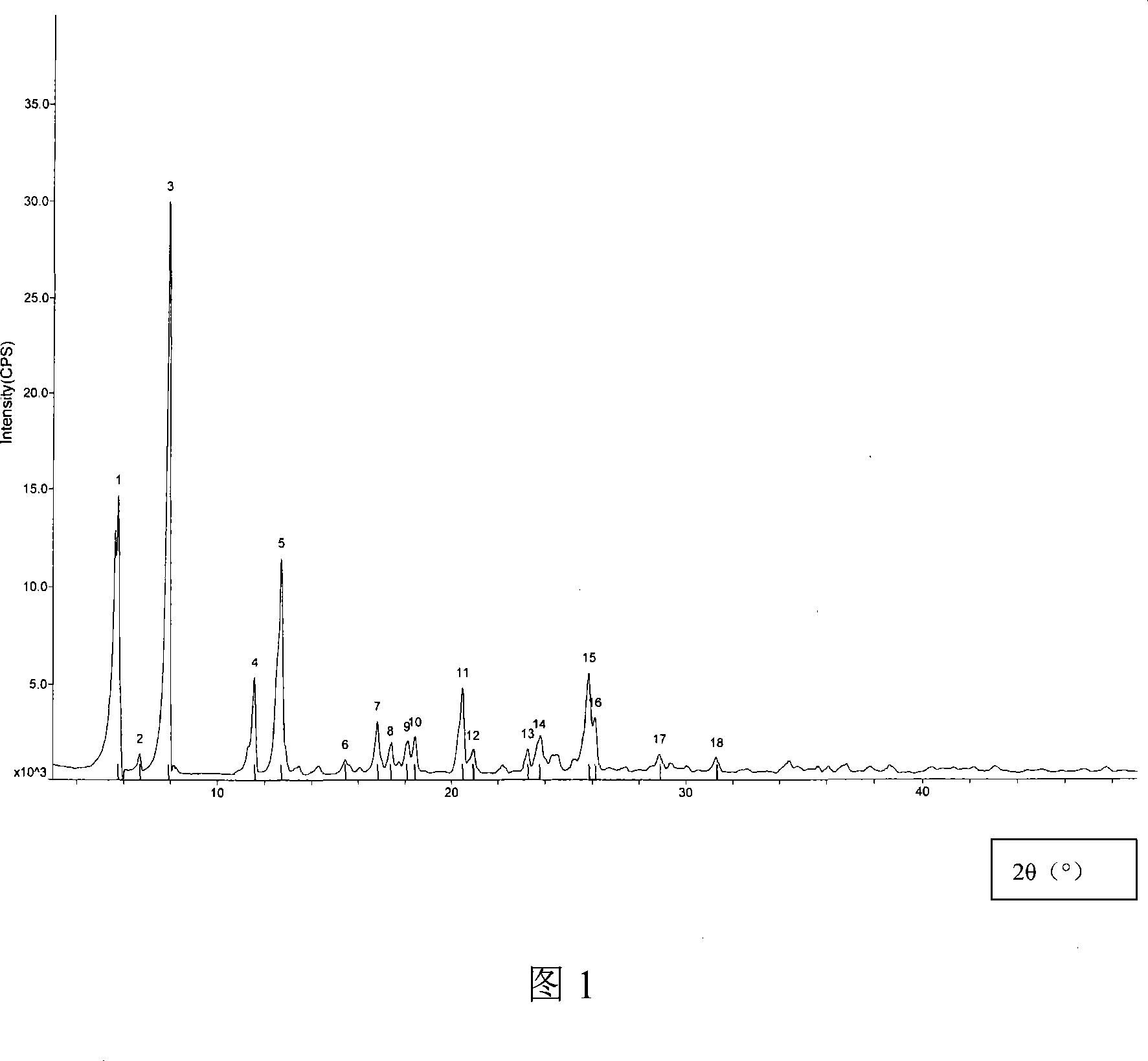

[0022] Powder X-ray Diffraction Analysis: The spectrum is shown in Figure 1; there are characteristic peaks at 5.78°, 7.94°, 11.60°, 12.72°, 20.50°, and 25.88°.

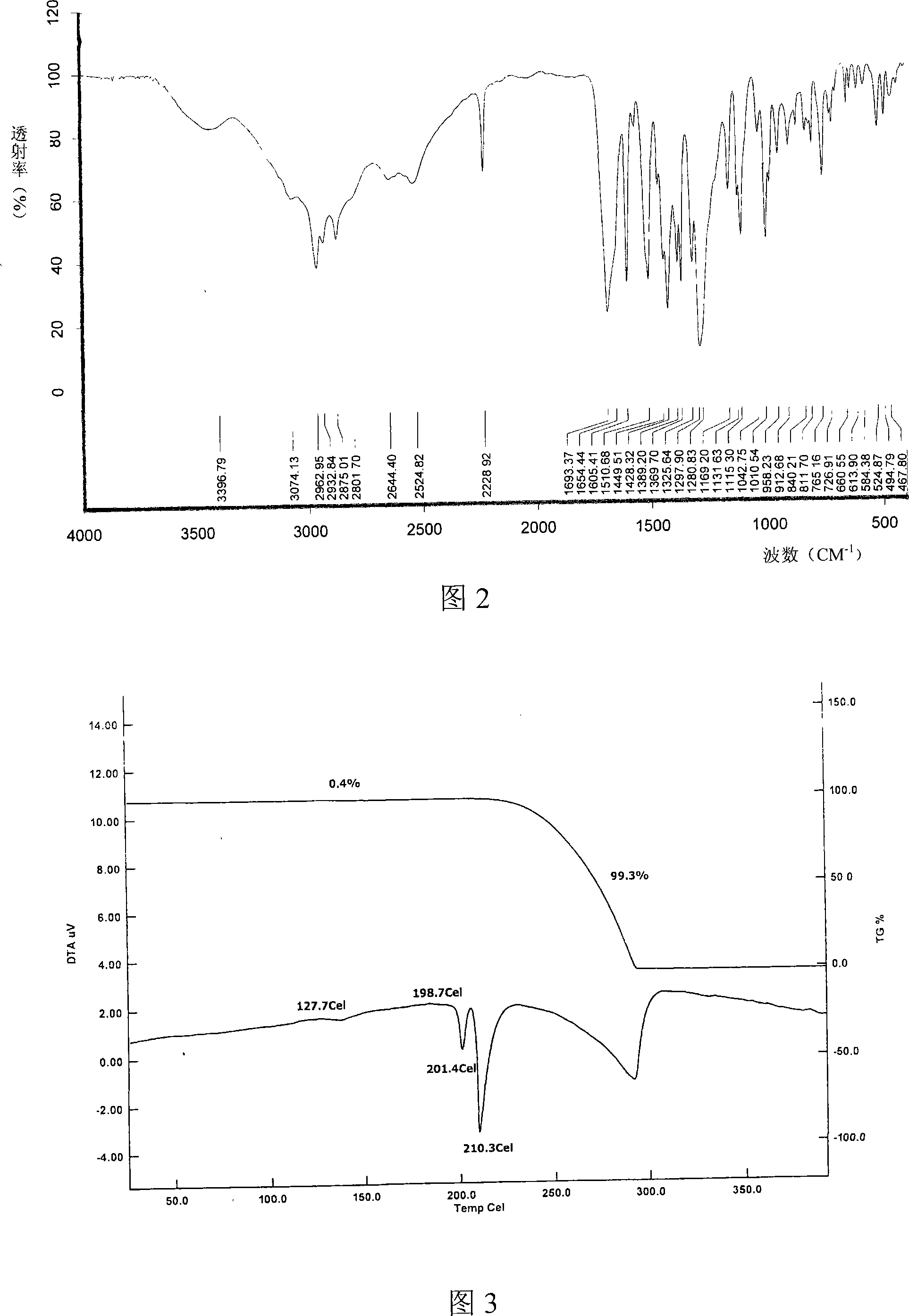

[0023] IR Analysis: The infrared IR spectrum of Fourier transform is shown in Figure 2.

[0024] Particle size analysis: the particle size distribution diagram is shown in Figure 4; statistical particle size D 10 2.779 μm, D 50 11.24 μm, D 90 38.14μm, average diameter 16.73μm.

Embodiment 2

[0026] Add 100g of febutadate crude product and 2000ml of ethyl acetate into a 5L round-bottomed flask, heat up to reflux, stir until completely dissolved, then filter while hot, place the filtrate in an ice-water bath at 0°C to cool, crystallize, filter, and filter The cake was washed with a small amount of ethyl acetate, and dried under vacuum at 80°C for 4 hours to obtain 88.4 g of solid.

[0027] Particle size analysis: The particle size distribution diagram measured by laser diffraction method is shown in Figure 5; the statistical particle size D 10 1.160 μm, D 50 10.36 μm, D 90 36.03μm, average diameter 15.07μm.

Embodiment 3

[0029] Capsule preparation.

[0030] The microcrystal 40g that embodiment 1 prepares

[0031] Medicinal Lactose 90g

[0032] 30g pregelatinized starch

[0033] Carboxymethyl Starch Sodium 12g

[0035] A total of 1000 capsules were made

[0036] Preparation process: Mix the components other than magnesium stearate in the prescription evenly, use an appropriate amount of 3% (w / w) povidone K29 / 31 aqueous solution as a binder, make a soft material, and extrude the same for 14 Mesh sieves into wet granules, ventilate and dry at 80°C for 2 hours, pass the dry granules through a 14-mesh sieve for granulation, add the remaining magnesium stearate, mix evenly, fill in No. 2 gelatin capsules, and get ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com