Steel desulfurizing method

A technology for molten steel and steelmaking furnace, applied in the field of metallurgy, can solve the problems of complex process and high difficulty in realization, and achieve the effect of reducing the difficulty and simplifying the desulfurization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

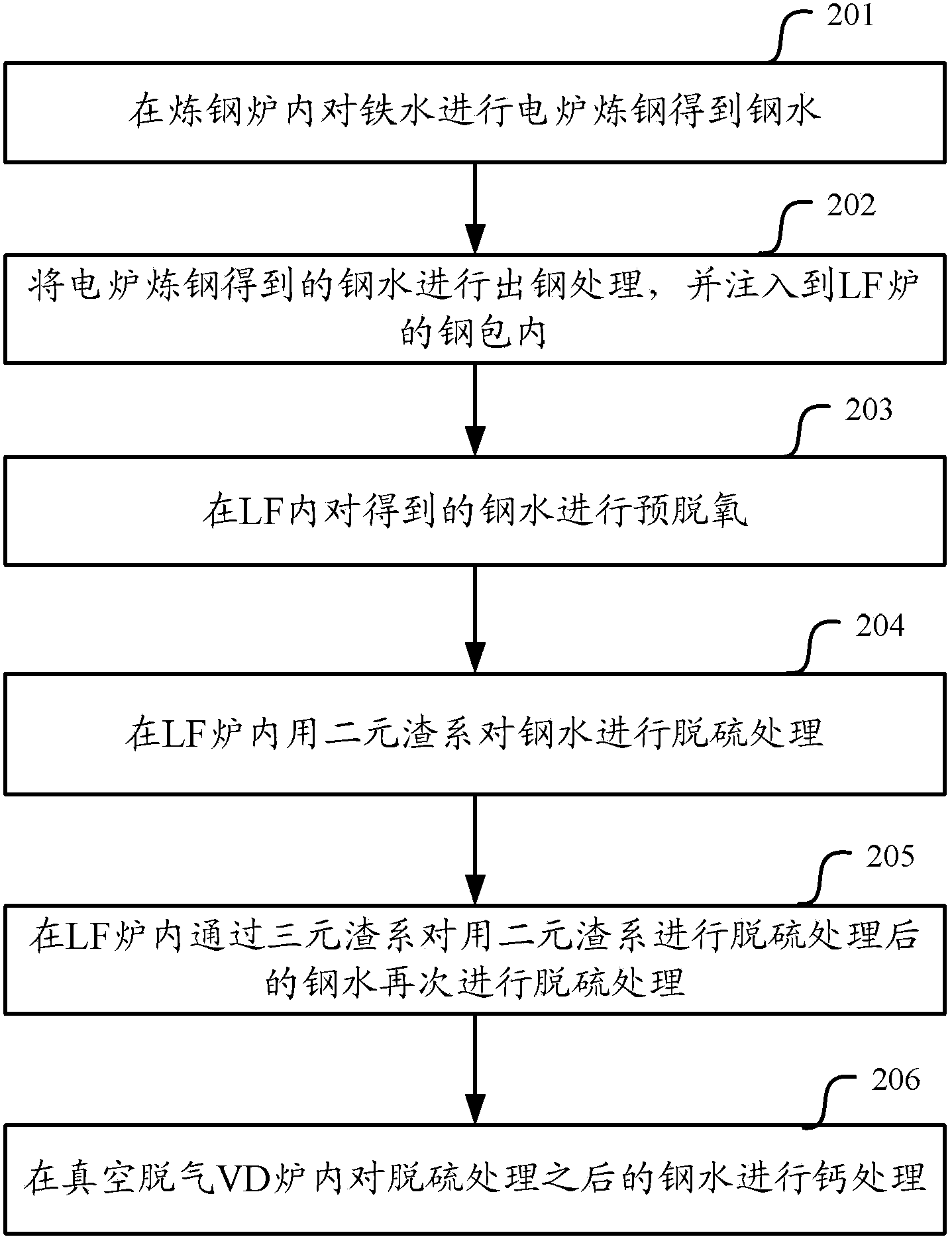

[0024] In the embodiment of the present invention, molten iron is subjected to electric furnace steelmaking in a steelmaking furnace to obtain molten steel; in the ladle refining furnace LF, the molten steel is desulfurized through a slag system. Since the sulfur content in the steel can be reduced in the existing steelmaking equipment without the need to build additional equipment for pretreatment of molten iron, the process of desulfurizing the steel is simplified and the difficulty of implementation is reduced.

[0025] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

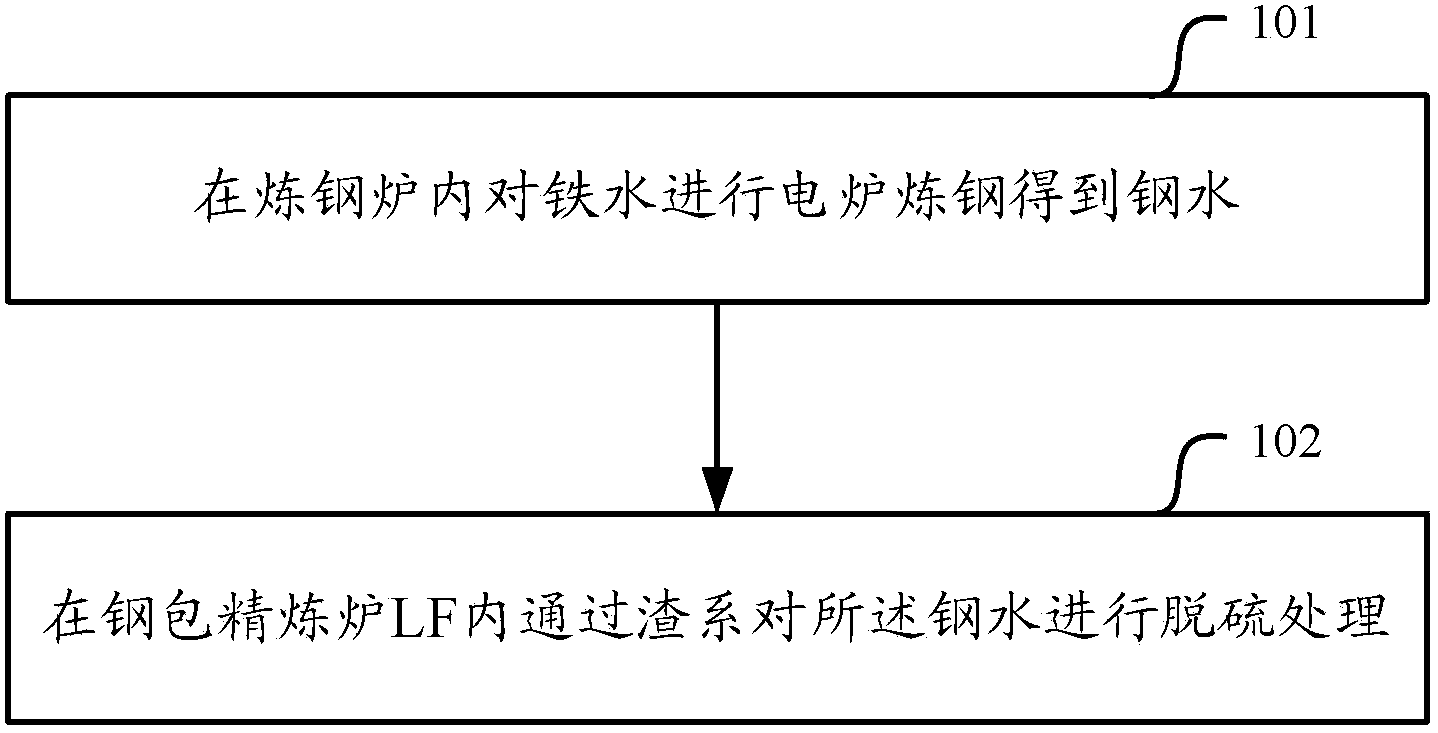

[0026] Such as figure 1 As shown, the embodiment of the present invention carries out the method for desulfurizing steel comprising the following steps:

[0027] Step 101, performing electric furnace steelmaking on molten iron in a steelmaking furnace to obtain molten steel;

[0028] Step 102, desulfurize the molten steel thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com