Deepwater bagged sand construction device and deepwater bagged sand construction technology

A construction device and bagged sand technology, applied in infrastructure engineering, construction, etc., can solve problems such as distortion, complicated water flow, and bulky volume, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

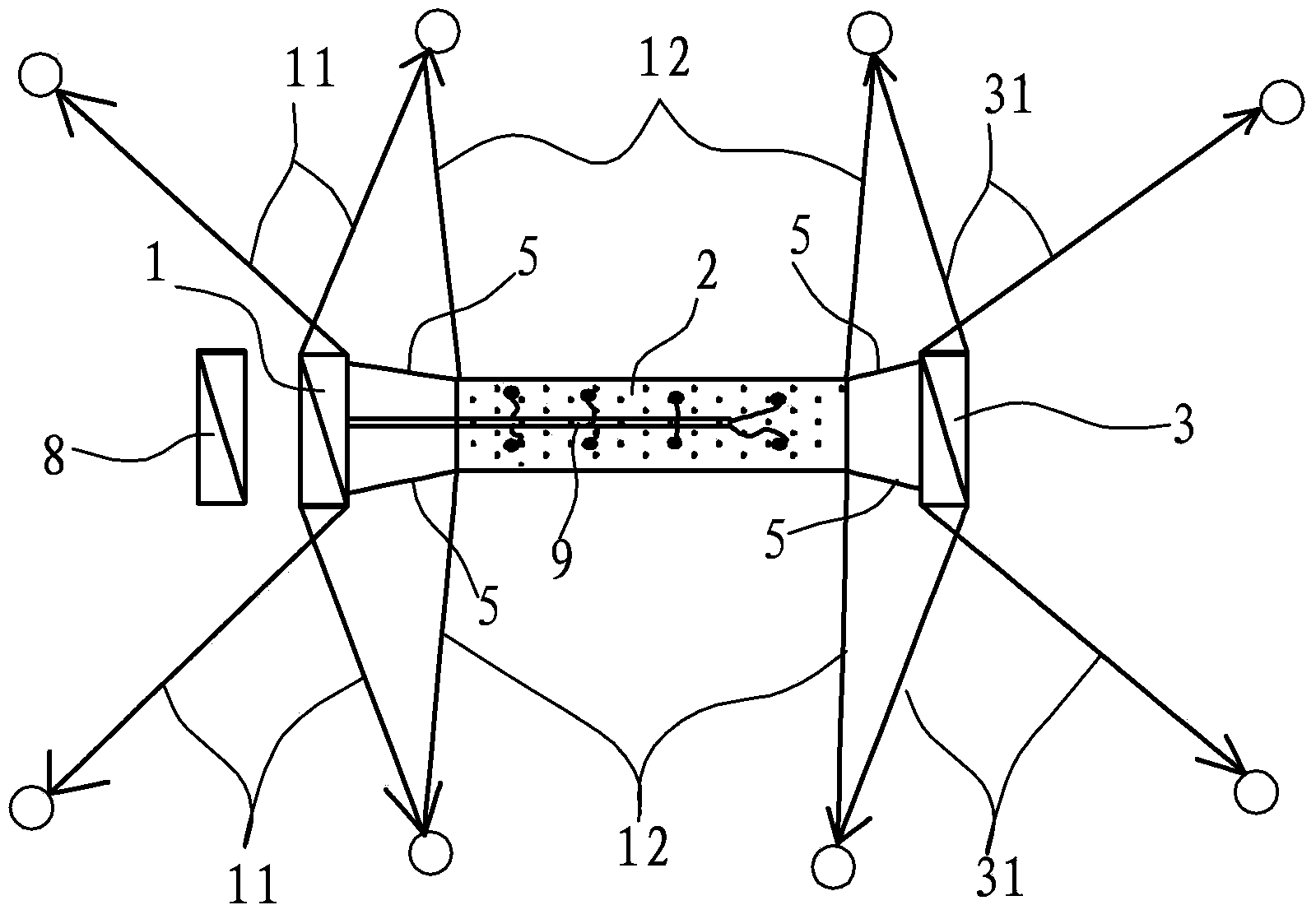

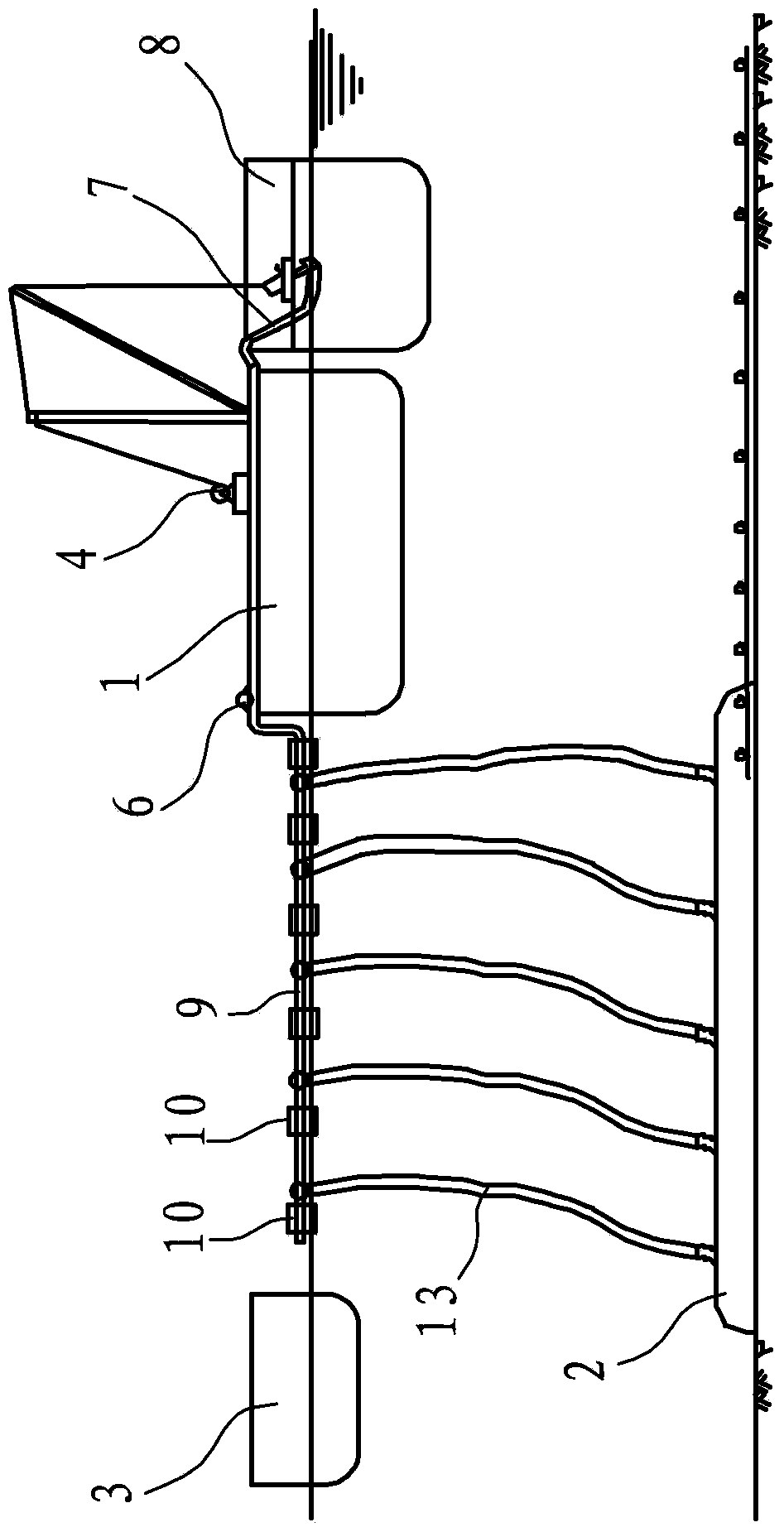

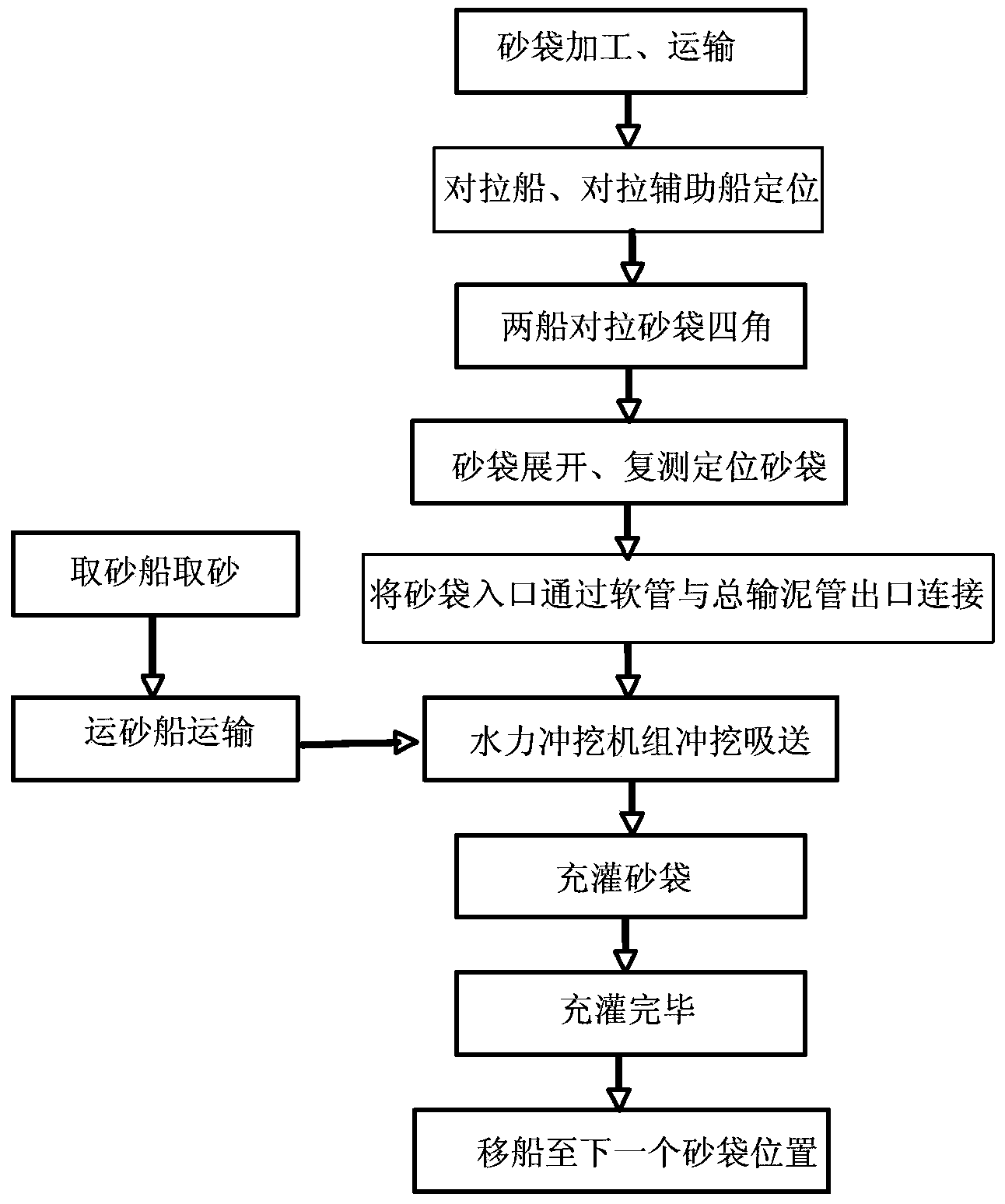

[0018] like figure 1 , figure 2 The shown deep-water bagged sand construction device includes a pair-pull ship 1 arranged on one side of the sand bag 2, a pair-pull auxiliary ship 3 arranged on the other side of the sand bag 2 and paired with the pair-pull ship 1, and the pair-pull ship 1 It is fixed by two figure-of-eight opposite pull anchor cables 11 at the front and rear, and the auxiliary pull ship 3 is also fixed by two figure eight opposite pull auxiliary anchor cables 31 at the front and rear. Two winches 4 are arranged on the pull vessel 1, and Two winches 4 are also arranged on the pulling auxiliary ship 3, and the four corners of the sand bag 2 are respectively connected with four stay ropes 5 by slip knots, and the other ends of the two stay ropes on the same side as the opposite pull boat 1 are respectively fixed on the opposite...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap