Top microwave drying equipment and drying method

A technology for microwave drying and tops, applied in the field of textile dyeing and finishing, can solve the problems of microwave drying and over-drying, and achieve the effect of automatic matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

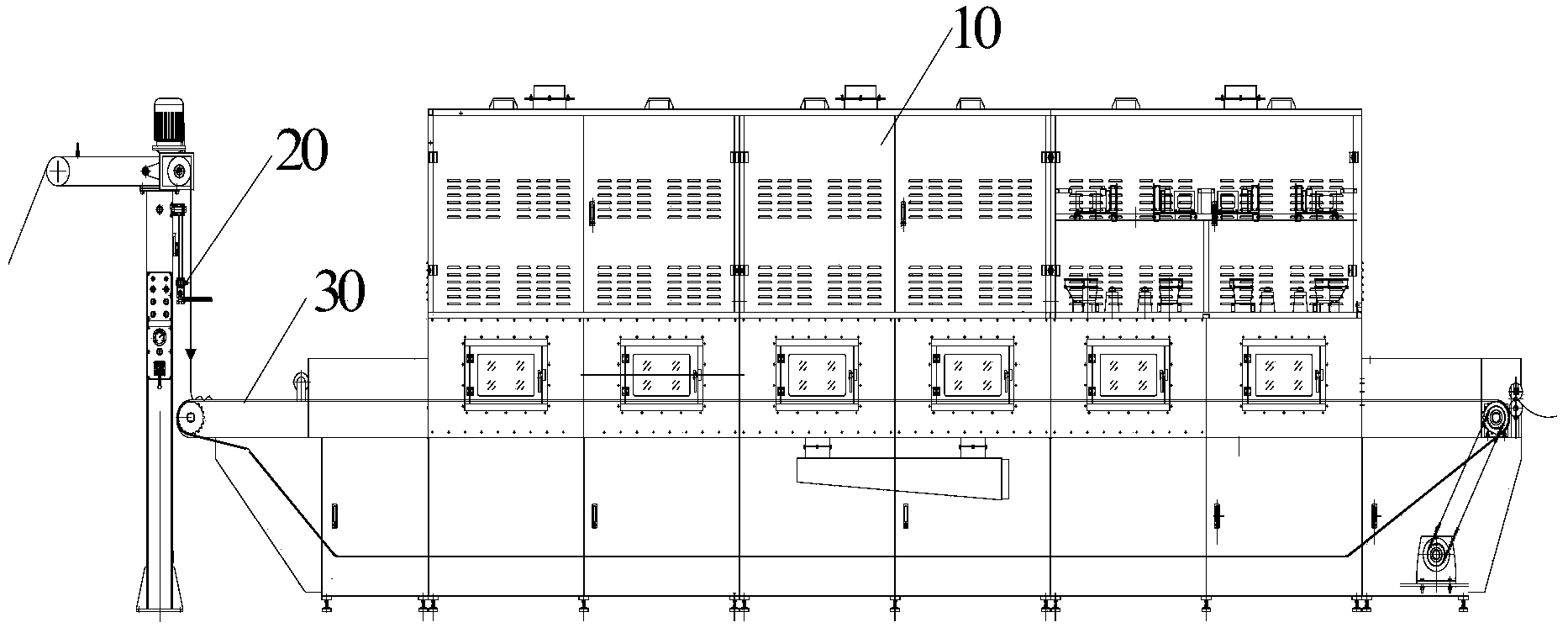

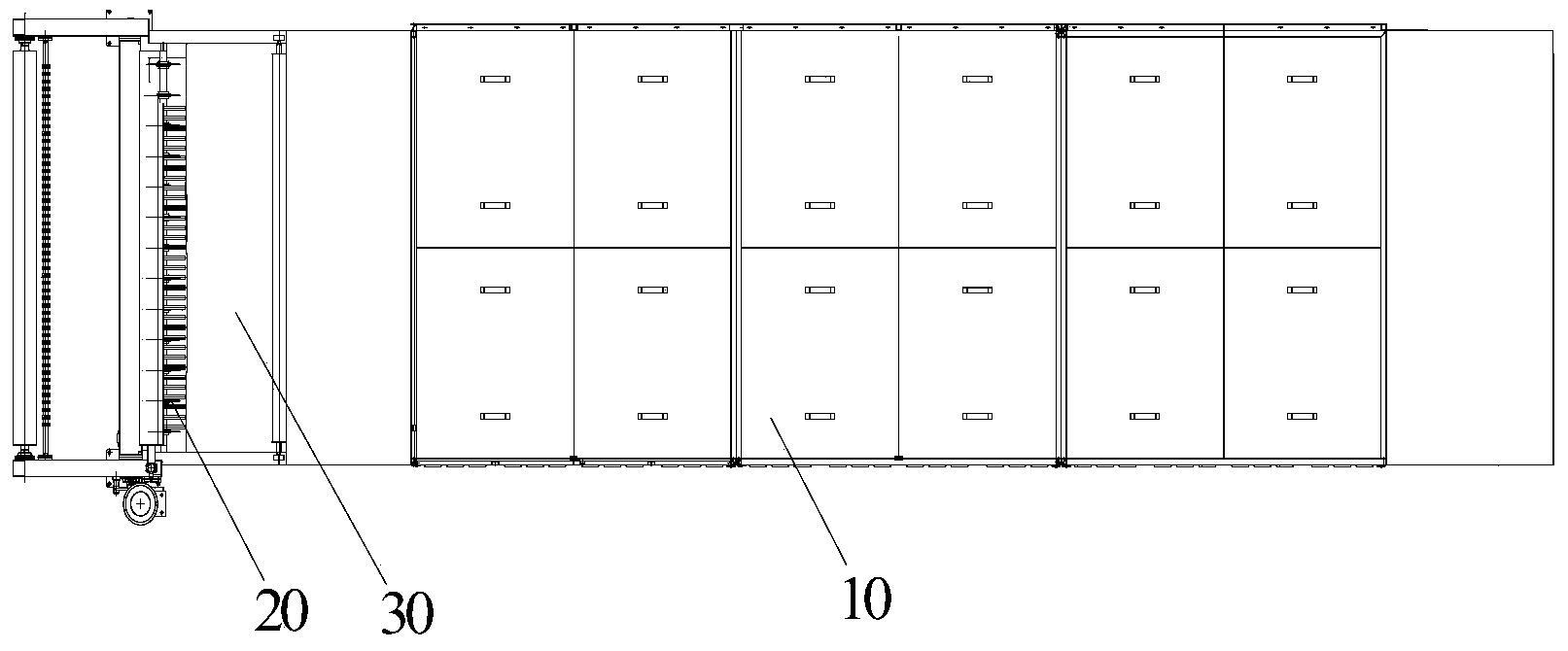

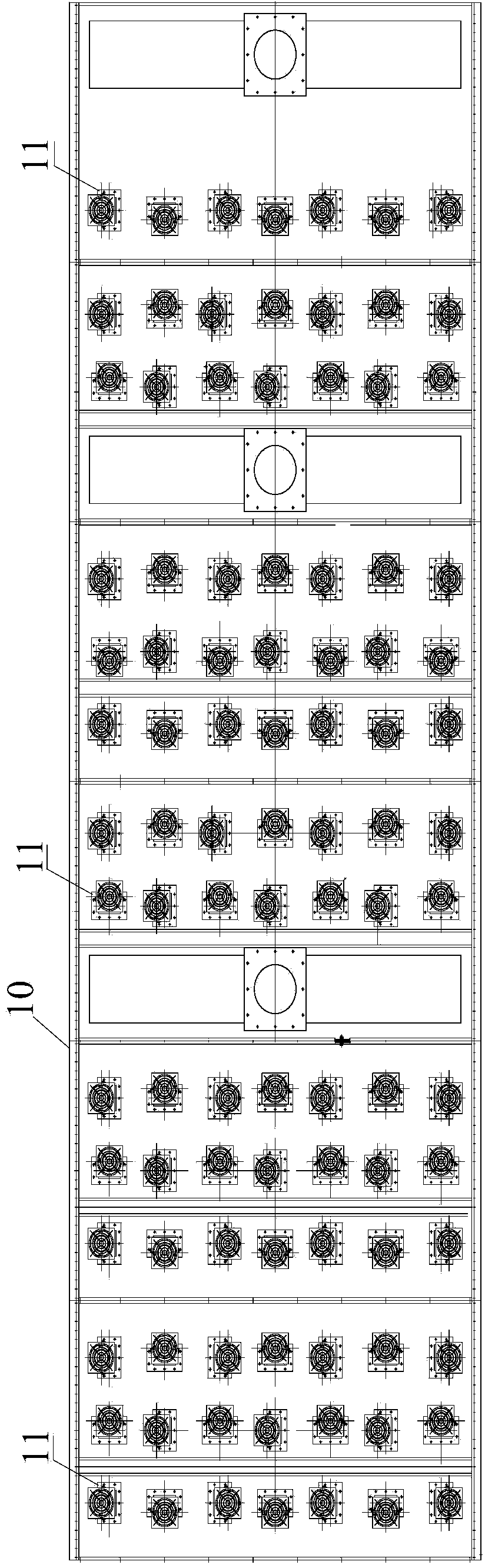

[0023] see figure 1 and figure 2 According to the wool top microwave drying equipment of the present invention, comprising a microwave drying section 10, a microwave heating element 11 is arranged in the microwave drying section 10; a wool top quantity detection device 20 detects the quantity of wool tops to be dried inputted; a controller , control the microwave heating element 11 according to the detection result of the sliver number detection device 20 . The number of wool tops is monitored by using the number detection device of wool tops, and then the heating power of the microwave heating element and the number of switches are adjusted by the controller to achieve real-time adjustment of the working state of the energy output device and real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com