Array substrate and manufacturing method thereof and 3D (three-dimensional) display device

A technology of an array substrate and a manufacturing method, which is applied in the field of 3D display, and can solve problems such as difficulty in alignment and lamination of a grating substrate and a display screen, inability to improve the brightness of a display device, and low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

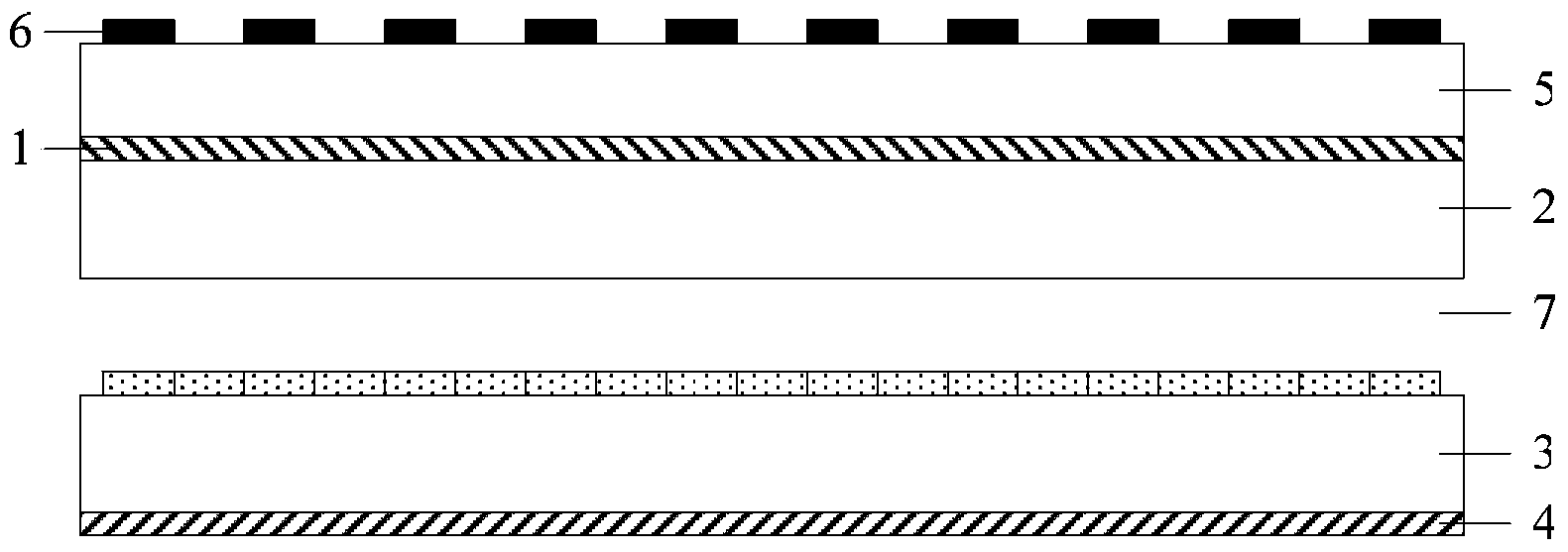

[0050] The array substrate provided by this embodiment is as Figure 4As shown, it includes: a base substrate 100 (a glass substrate or a transparent substrate of quartz material) and a pixel array layer 200 located above the base substrate 100, and also includes: a number of baffles located below the base substrate 100 with predetermined distances The grating layer formed by the light stripes.

[0051] In this embodiment, the light-shielding strip includes: a light-shielding layer 410 and a light-reflecting layer 420 , and the light-shielding layer 410 is located between the base substrate 100 and the light-reflecting layer 420 . To achieve a better 3D display viewing angle, the width and spacing of the light-shielding strips have been set in advance. In order not to affect the 3D display viewing angle, the projection of the light-reflecting layer 420 on the base substrate 100 is projected by the light-shielded layer 410 on the base substrate 100. projection overlay on .

...

Embodiment 2

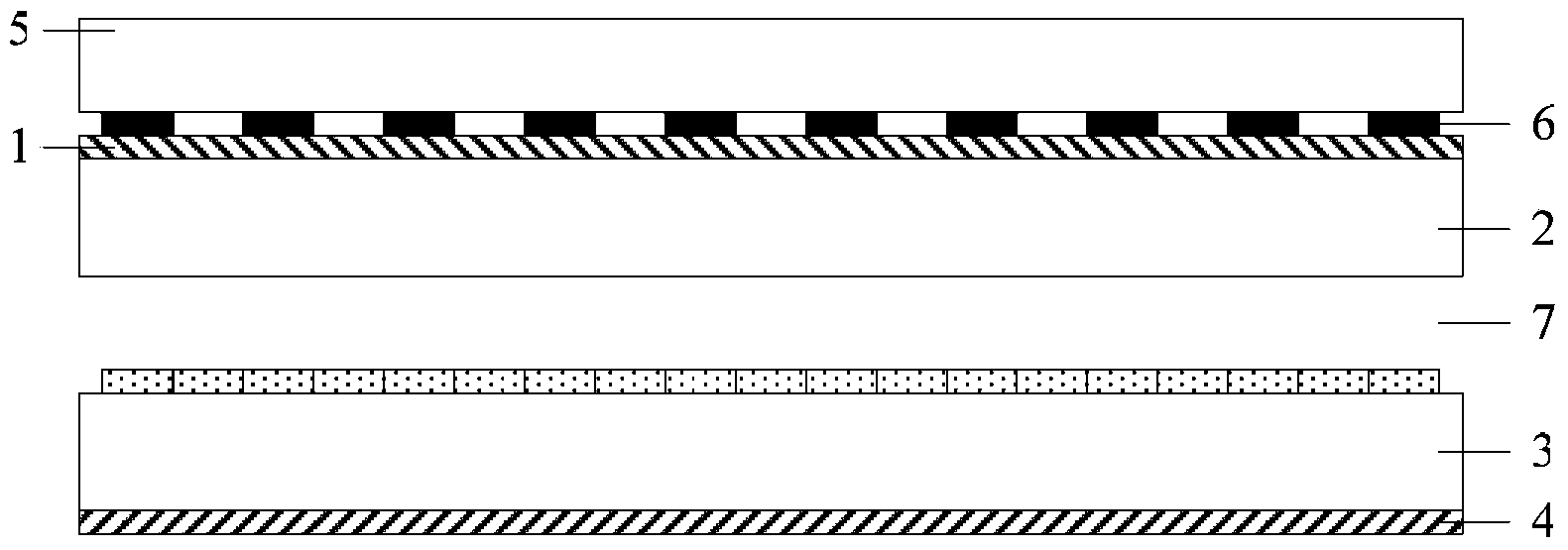

[0062] For a liquid crystal display device, a lower polarizer is required under the base substrate 100 . Therefore, on the basis of Embodiment 1, the array substrate of this embodiment further includes a polarizer formed on the side of the light blocking strip away from the pixel array layer. Such as Figure 5 As shown, the polarizer 300 is formed under the reflective layer 420 . During fabrication, the polarizer 300 is directly formed under the reflective layer 420 on the basis of the fabrication process in Embodiment 1. It is only necessary to ensure that the reflective layer 420 is formed before manufacturing the polarizer 300 .

[0063] Of course, if Figure 6 As shown, the polarizer 300 can also be formed between the light-shielding layer 410 of the light-shielding strip and the base substrate 100, that is, the light-shielding layer 410 is directly formed on the lower surface of the polarizer 300, and the light-reflecting layer 420 is formed on the lower surface of the ...

Embodiment 3

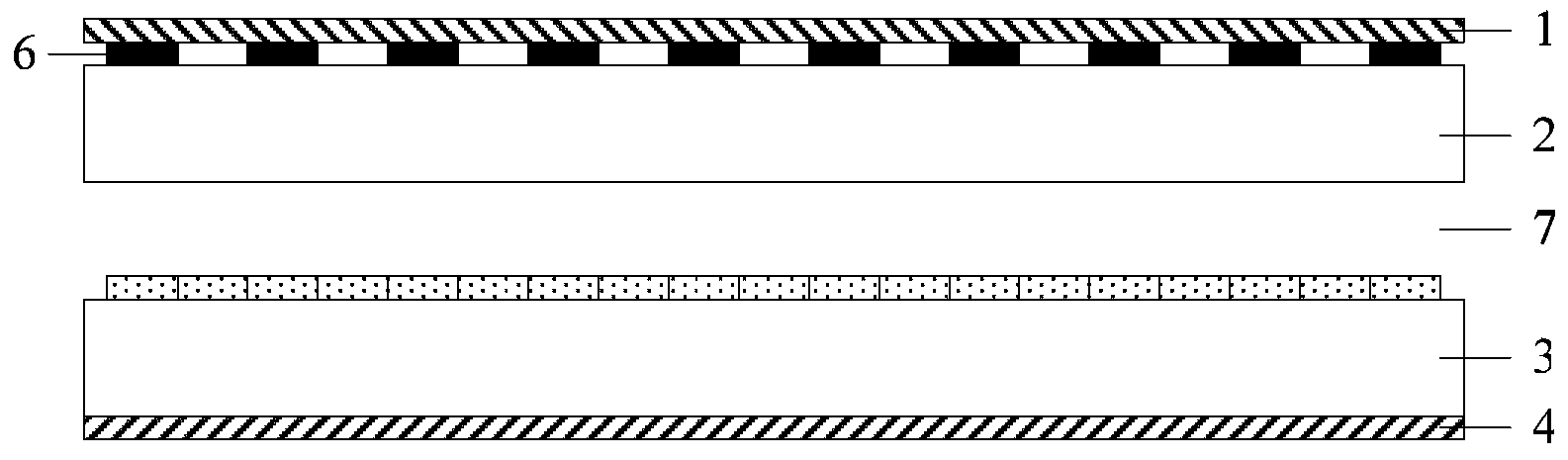

[0074] The array substrate of this embodiment is such as Figure 7 As shown, it includes: a base substrate 100 (a glass substrate or a transparent substrate of quartz material) and a pixel array layer 200 located above the base substrate 100, and also includes: a number of baffles located below the base substrate 100 with predetermined distances The grating layer formed by the light strip 400'.

[0075] In this embodiment, the light blocking strip 400' is made of reflective material. Preferably, the light blocking strip 400 ′ is directly formed on the lower surface of the base substrate 100 , so that the grating substrate is not needed, and the transmittance of light is increased. When directly formed, the light blocking strip 400 ′ is formed on the lower surface of the base substrate 100 by a patterning process (usually including processes such as photoresist coating, exposure, development, etching, and photoresist stripping). , improving the alignment accuracy of the sub-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com