A Calculation Method for Automatic Arranging Quantity of Stamping Parts in Parts Factory

A technology of automatic arrangement and calculation method, applied in the direction of calculation, electrical digital data processing, special data processing application, etc., can solve problems such as difficult adjustment and low efficiency, achieve job optimization management assistance, improve scientificity and executable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

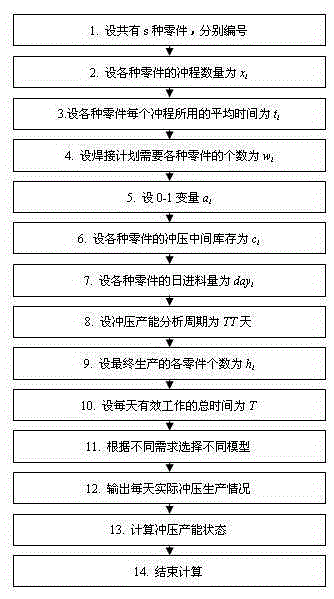

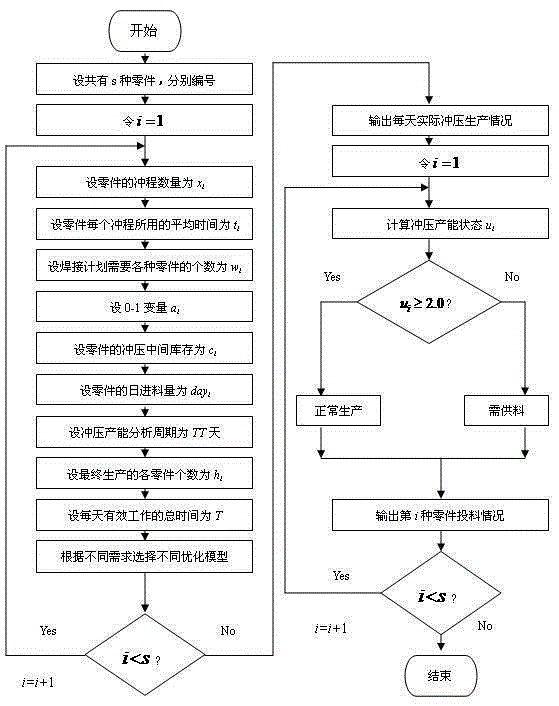

Method used

Image

Examples

Embodiment 1

[0031] (1) There are 6 kinds of parts, the first three are small parts and can be processed by large or small punching machines, the last three are large parts and can only be processed by large punching machines, respectively numbered i=1, 2,... ..., 6, where the number of large and small stamping machines is sufficient;

[0032] (2) Set the number of strokes of 6 parts x 1、 x 2 、x 3 、x 4 、x 5、 x 6 3, 4, 4, 5, 2, 3 respectively;

[0033] (3) Set the average time t of each stroke of the 6 parts 1、 t 2 , t 3 , t 4 , t 5、 t 6 8, 5.5, 7, 6, 6, 9 seconds respectively;

[0034] (4) Suppose that the welding plan requires the quantity w of 6 kinds of parts 1、 w 2 、w 3 、w 4 、w 5、 w 6 0, 1000, 0, 900, 300, 0 respectively;

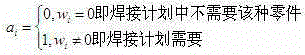

[0035] (5) Set 0-1 variable a 1、 a 2 、a 3 、a 4 、a 5、 a 6 The sequence is 0, 1, 0, 1, 1, 0;

[0036]

[0037] (6) Set the stamping intermediate inventory of 6 parts as c 1、 c 2 、c 3 、c 4 、c 5、 c 6 100, 200, 100, 300, 0, 0 respective...

Embodiment 2

[0049] (1) There are 6 kinds of parts, the first three are small parts and can be processed by large or small punching machines, the last three are large parts and can only be processed by large punching machines, respectively numbered i=1, 2,... ..., 6, sufficient quantity of factory size stamping machines;

[0050] (2) Set the number of strokes of 6 parts x 1、 x 2 、x 3 、x 4 、x 5、 x 6 3, 4, 4, 5, 2, 3 respectively;

[0051] (3) Set the average time t of each stroke of the 6 parts 1、 t 2 , t3 , t 4 , t 5、 t 6 8, 5.5, 7, 6, 6, 9 seconds respectively;

[0052] (4) Suppose that the welding plan requires the quantity w of 6 kinds of parts 1、 w 2 、w 3 、w 4 、w 5、 w 6 0, 1000, 0, 900, 300, 0 respectively;

[0053] (5) Set 0-1 variable a 1、 a 2 、a 3 、a 4 、a 5、 a 6 The sequence is 0, 1, 0, 1, 1, 0;

[0054]

[0055] (6) Set the stamping intermediate inventory of 6 parts as c 1、 c 2 、c 3 、c 4 、c 5、 c 6 100, 200, 100, 300, 0, 0 respectively;

[0056] (7...

Embodiment 3

[0067] (1) There are 6 kinds of parts, the first three are small parts and can be processed by large or small punching machines, the latter three are large parts and can only be processed by large punching machines, respectively numbered i=1, 2,... ..., 6. The small punching machine is insufficient, and a large punching machine is used instead;

[0068] (2) Set the number of strokes of 6 parts x 1、 x 2 、x 3 、x 4 、x 5、 x 6 3, 4, 4, 5, 2, 3 respectively;

[0069] (3) Set the average time t of each stroke of the 6 parts 1、 t 2 , t 3 , t 4 , t 5、 t 6 8, 5.5, 7, 6, 6, 9 seconds respectively;

[0070] (4) Suppose that the welding plan requires the quantity w of 6 kinds of parts 1、 w 2 、w 3 、w 4 、w 5、 w 6 0, 1000, 0, 900, 300, 0 respectively;

[0071] (5) Set 0-1 variable a 1、 a 2 、a 3 、a 4 、a 5、 a 6 The sequence is 0, 1, 0, 1, 1, 0;

[0072]

[0073] (6) Set the stamping intermediate inventory of 6 parts as c 1、 c 2 、c 3 、c 4 、c 5、 c 6 100, 200, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com