Technological analysis-based ERP production planning management software

A technology for process analysis and production planning, applied in computing, data processing applications, instruments, etc., can solve the problems of inaccurate feedback data and time delays, lack of dynamic feedback mechanisms, and inadequate implementation of plans, saving auxiliary man-hours and realizing Controllability, the effect of increasing value-added benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

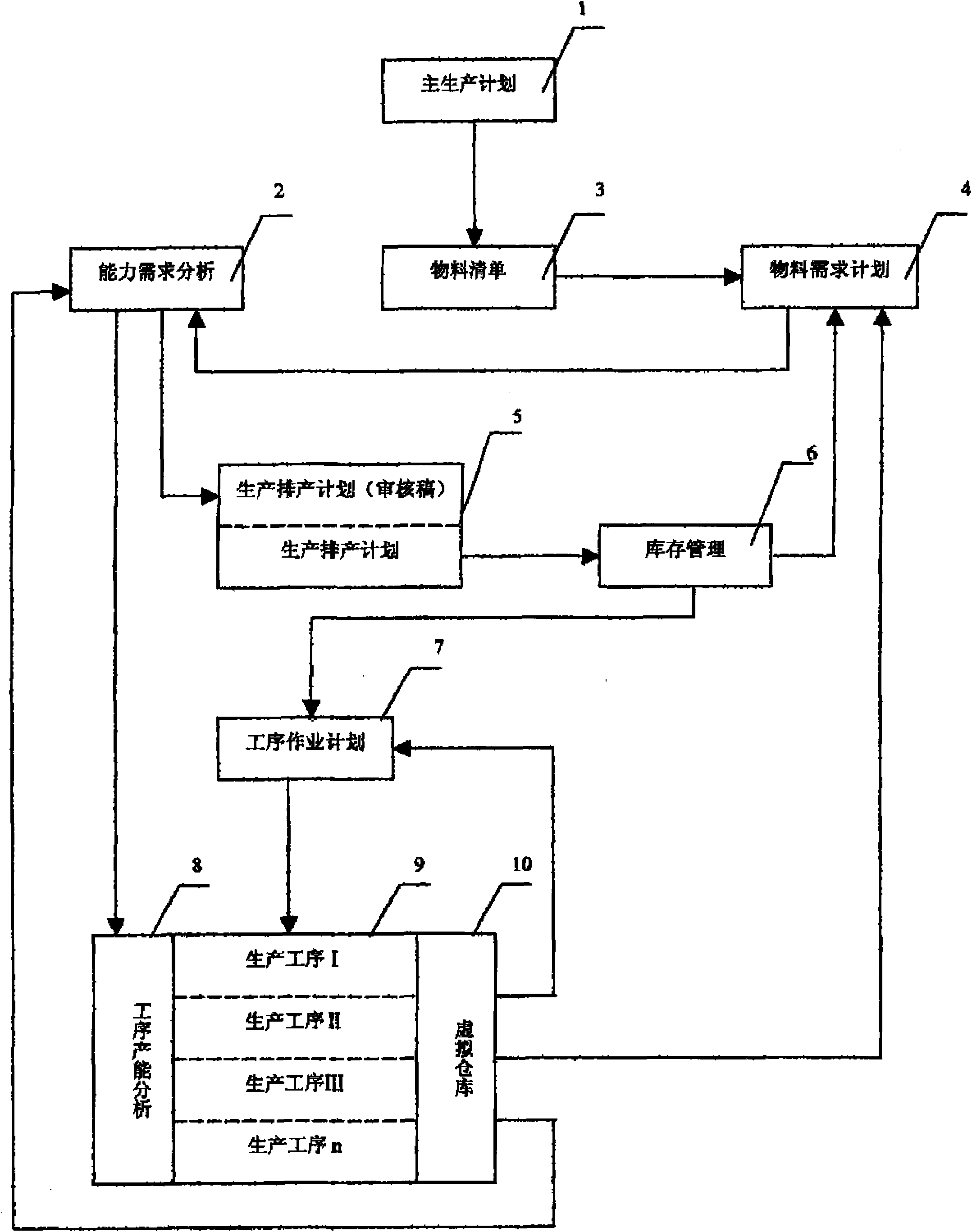

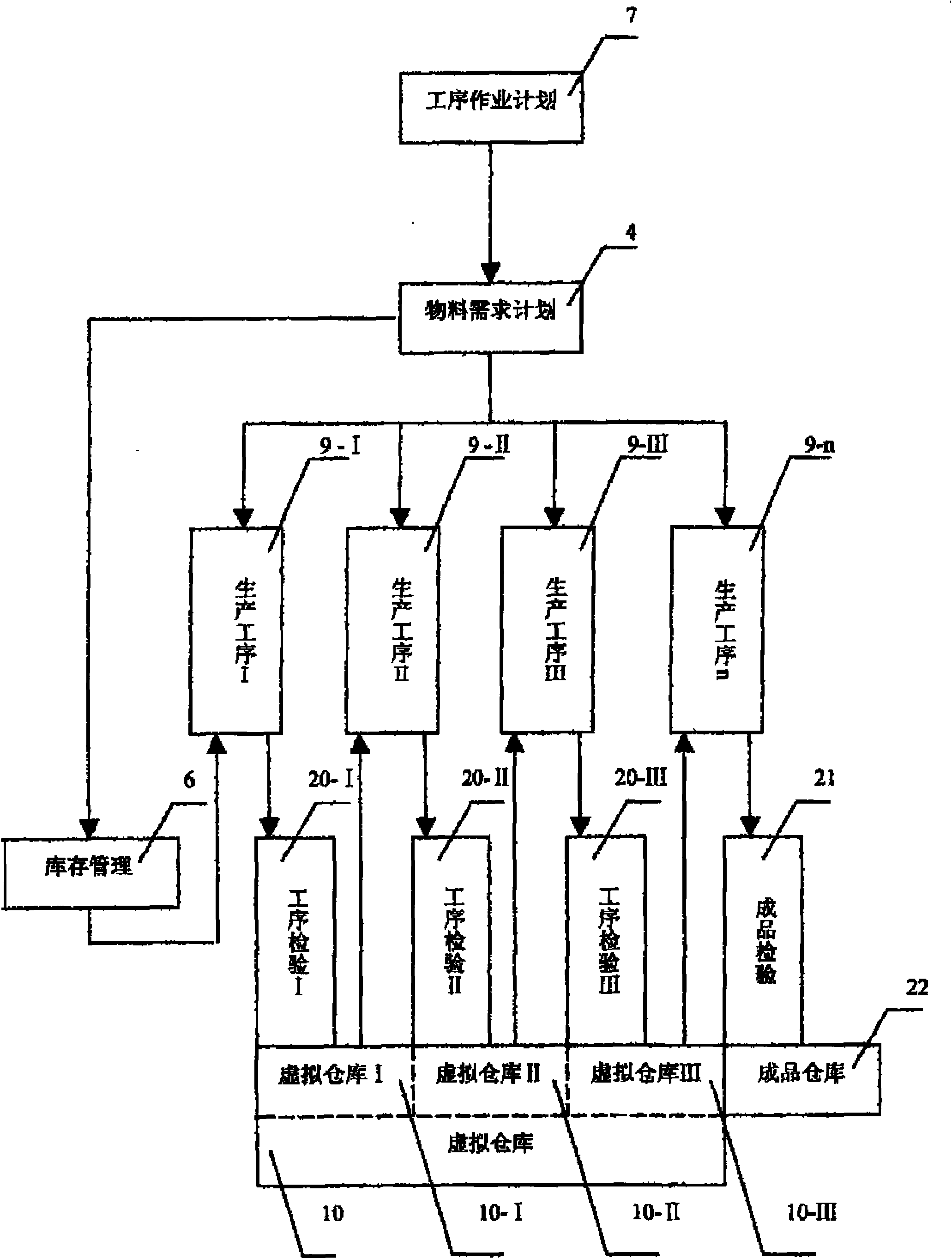

[0013] exist figure 1 Among them, the operation of the master production plan (1) on the bill of materials (3), inventory management (6), and virtual warehouse (10) generates the material requirement plan (4), and the capacity requirement plan (2) generates the material requirement plan (4) according to the material requirement plan (4) Process capacity analysis (8) calculates and generates production scheduling plan (review draft) (5), generates production scheduling plan after review and confirmation (5) generates process operation plan after verifying the corresponding material demand through inventory management (6) ( 7), the execution of each production process (9) is fed back to the capacity demand plan (2), the material demand plan (4), and the process operation plan (7) through the virtual warehouse (10).

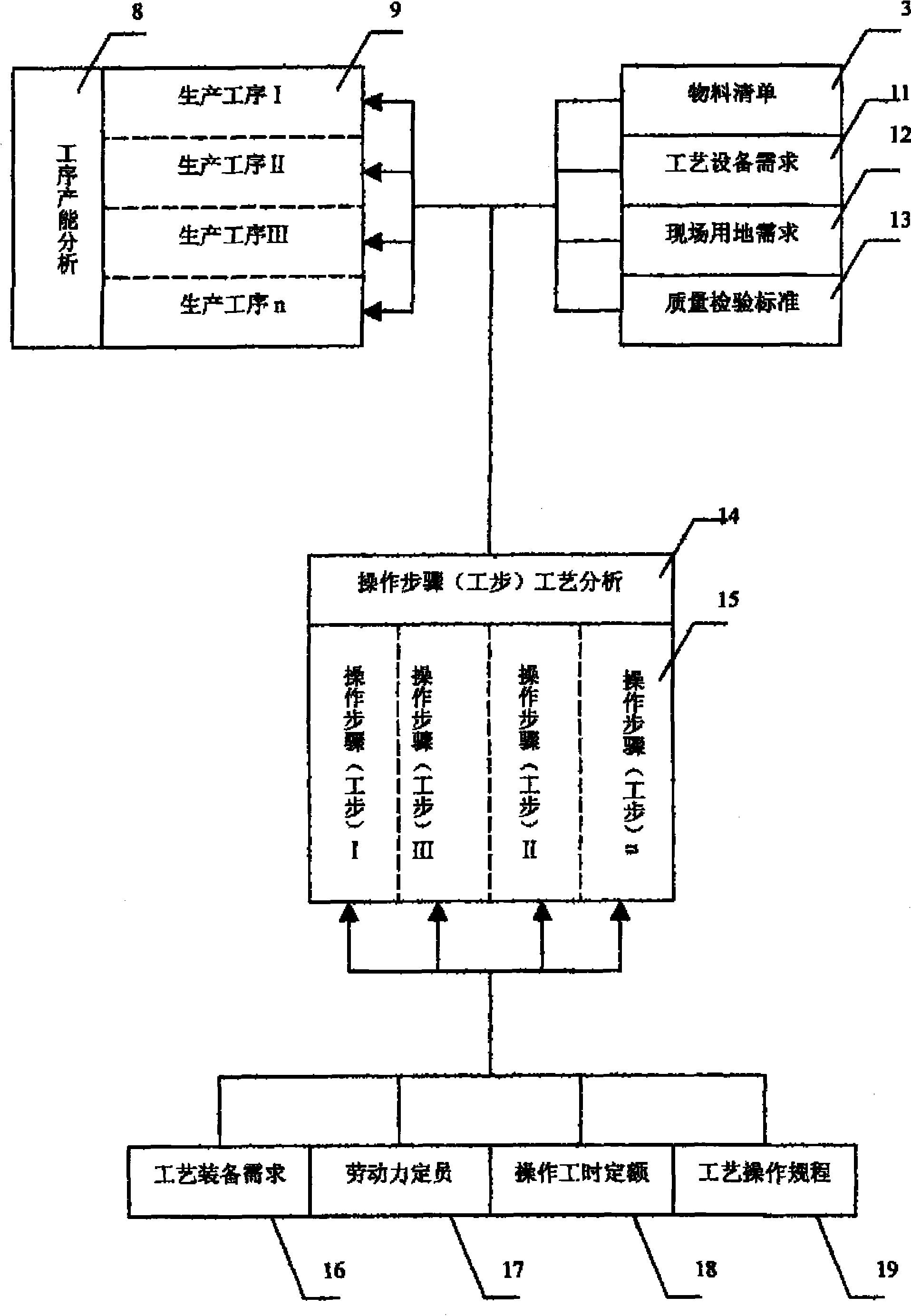

[0014] exist figure 2 In the shown embodiment, the process capacity analysis (8) is to carry out the bill of materials (3), process equipment requirements (11), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com