Agonist utilizing compression tights and production method for same

A manufacturing method and technology of tights, applied in the field of sportswear, can solve problems such as supporting prime mover angle considerations, and achieve the effects of preventing muscle strain, slowing down vasoconstriction, and increasing oxygen supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

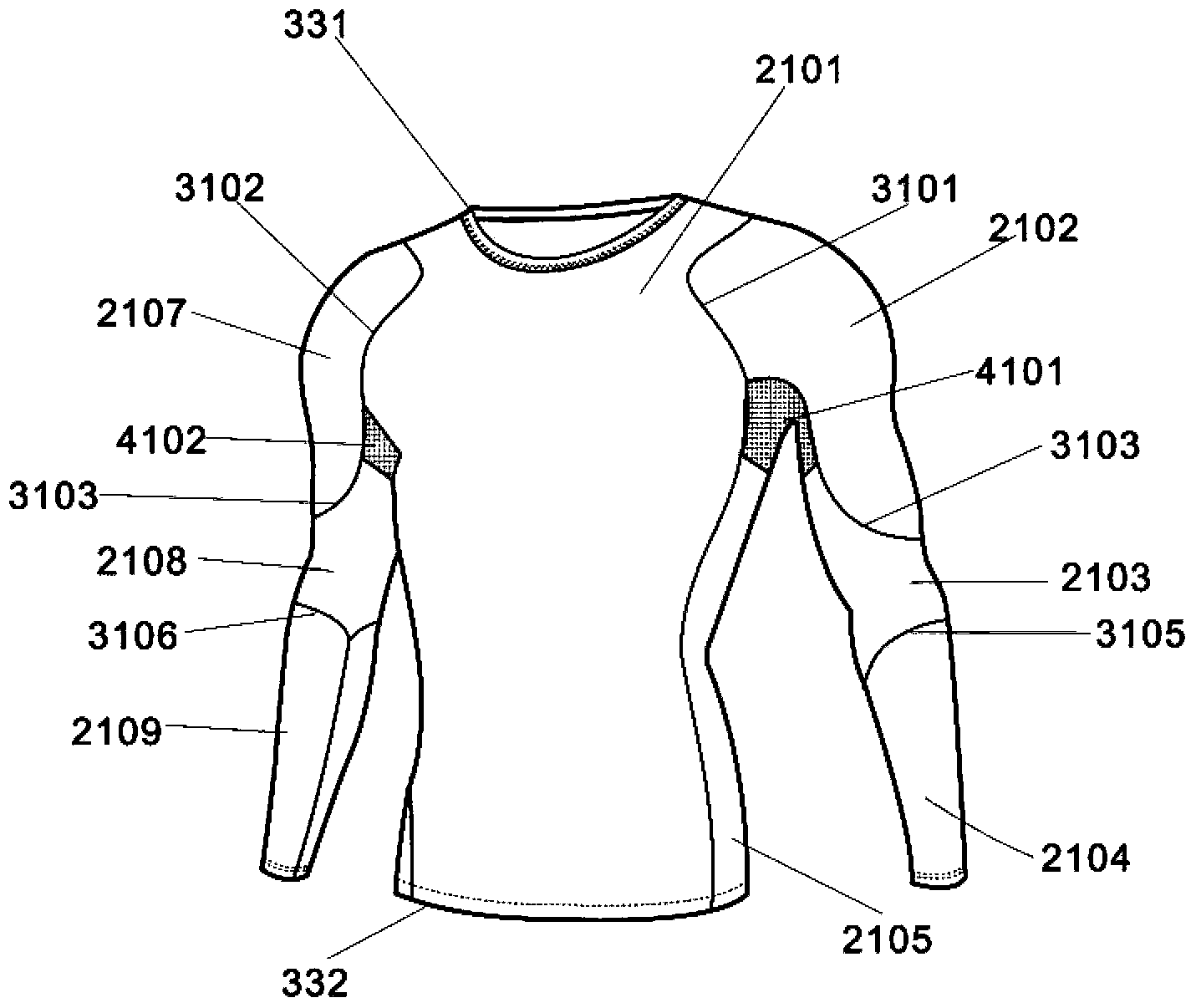

[0056] Front abdomen patchwork 2401, left thigh front patchwork 2402, left thigh side patchwork 2403, left knee patchwork 2404, left calf patchwork 2405, left hip patchwork 2406, left thigh backside patchwork 2407, Left foot bare patch 2408, right thigh front patch 2409, right thigh patch 2410, right knee patch 2411, right calf patch 2412, right hip patch 2413, right thigh patch 2414, right foot bare The stitching between the patchwork 2415, the back waist breathable mesh cloth 4401 and the crotch bottom breathable mesh cloth 4402 is stitched with the splicing seam 300, specifically: the front abdomen patchwork is spliced to the left and right thigh front patchwork 2402 through the splicing seam 3401 , 2409, the left and right thigh front patchwork 2402, 2409 are spliced to the left and right knee patchwork 2404, 2411 through the splicing seam 3402, 3403, and the left and right knee patchwork 2404, 2411 are spliced to the left side through the splicing seam 3404, 3405 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com