Multi-layer baking solidification dispensing machine achieving automatic feeding and discharging

An automatic loading and unloading and dispensing machine technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems that cannot meet the needs of mass production, the number of liquid crystal display modules is not large, and the baking and curing function is single. , to achieve the effect of saving length and space, improving production efficiency and product quality, and high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but the following descriptions are only preferred embodiments of the present invention and do not limit the protection scope of the present invention.

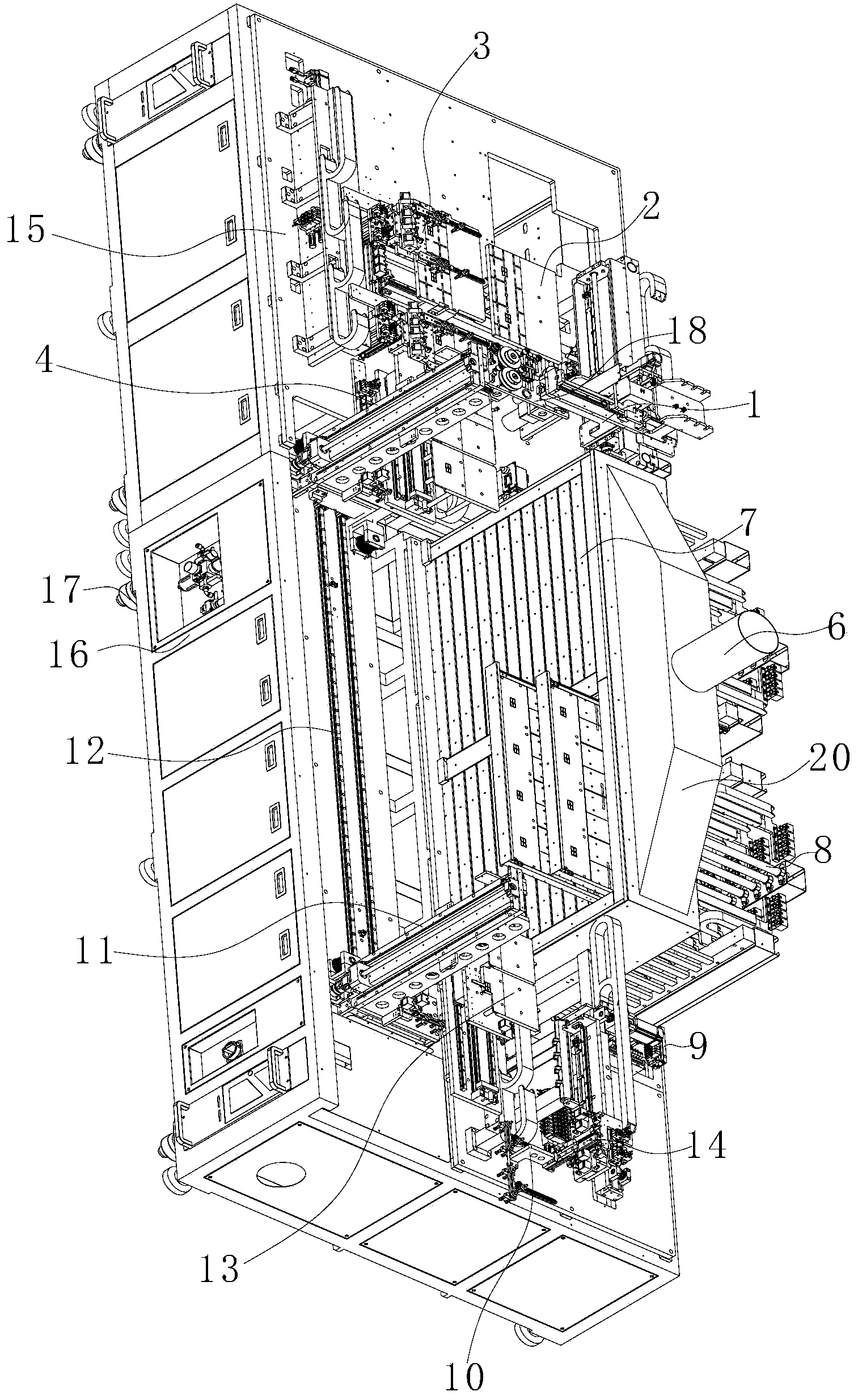

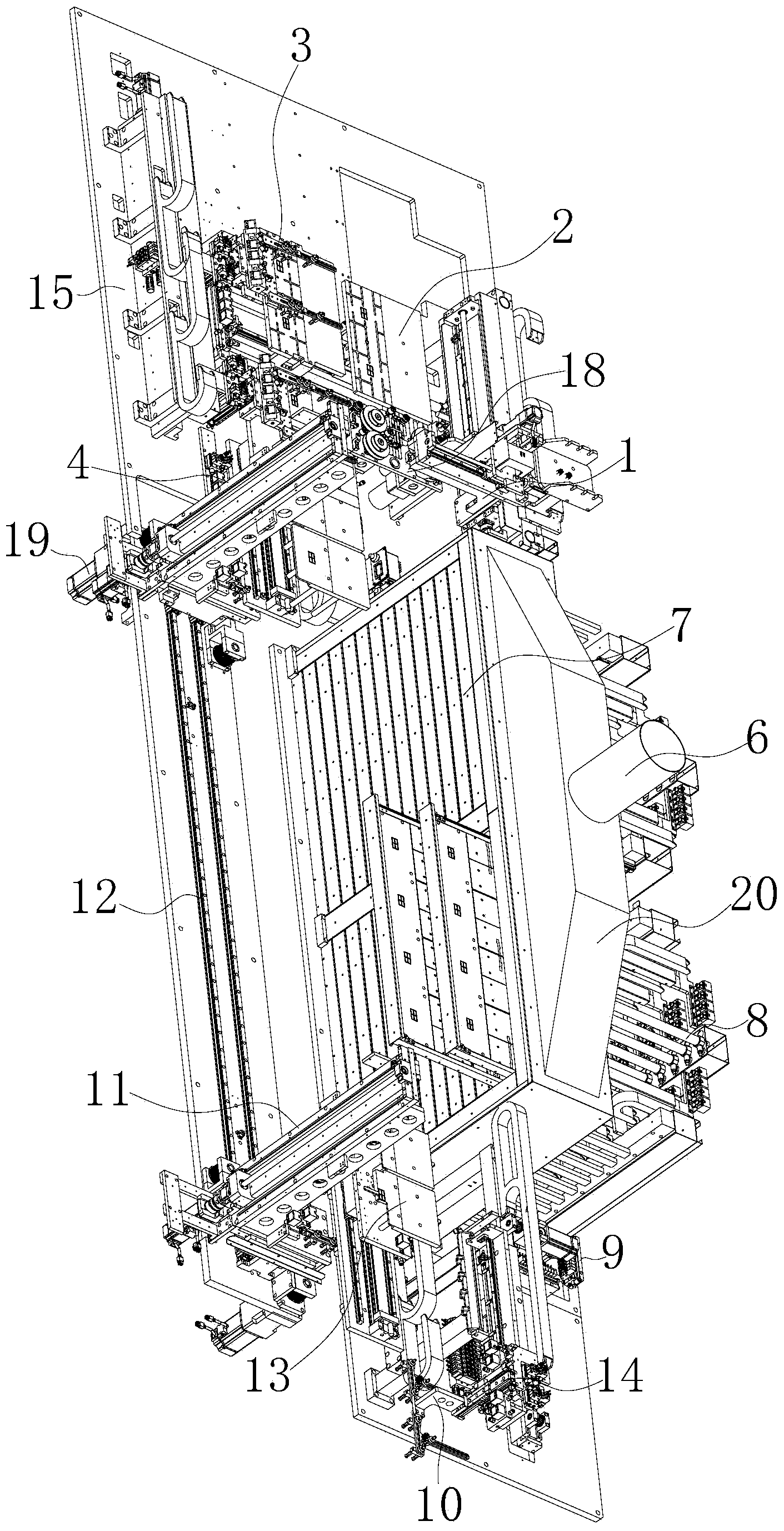

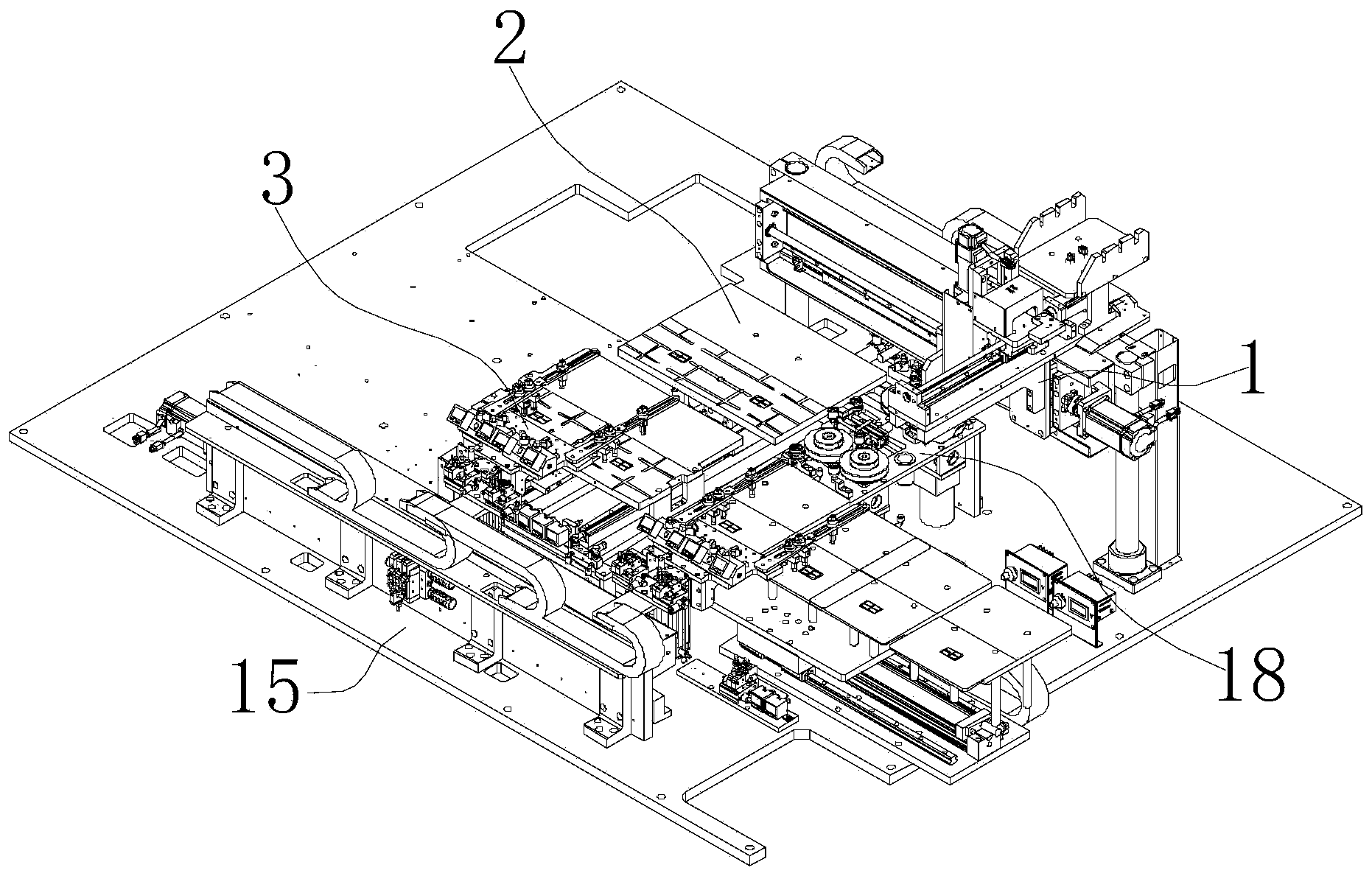

[0028] Automatic loading and unloading multilayer baking curing glue dispenser, such as Figure 1-2 As shown, it includes a reclaiming module 4, a baking and curing module, and a blanking module 11. The reclaiming module 4, the bake curing module and the blanking module 11 are installed on the bottom plate 15 respectively. The reclaiming module 4 and the unloading module 11 are installed on the slide rail 12 beside the baking curing module. The baking and curing module includes a curing furnace body 20 and a number of baking and curing conveying plates 7 movably installed in the curing furnace body 20 layer by layer. The baking and curing conveying plates 7 are connected to a first driving device. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com