Rocking pneumatic impact machine

A beater and swing-type technology, which is applied in the field of grading and dehydration supporting equipment in the coal washing and preparation industry, can solve the problems of not being able to adapt to the harsh environment of coal slime water, the structure of the mechanically driven beater, and the effect of blocking particulate matter removal, etc., and achieve the overall structure Simple and practical, meet the needs of harsh working conditions, and strengthen the effect of hitting and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

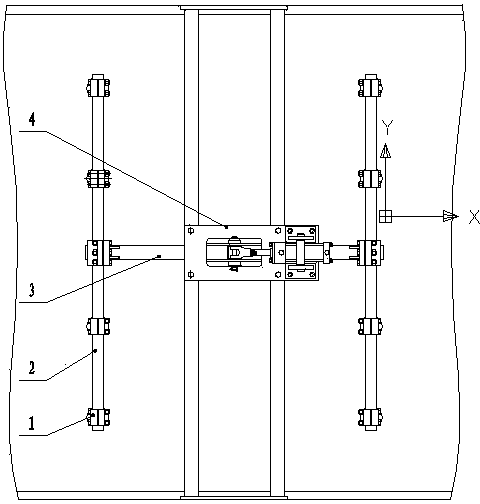

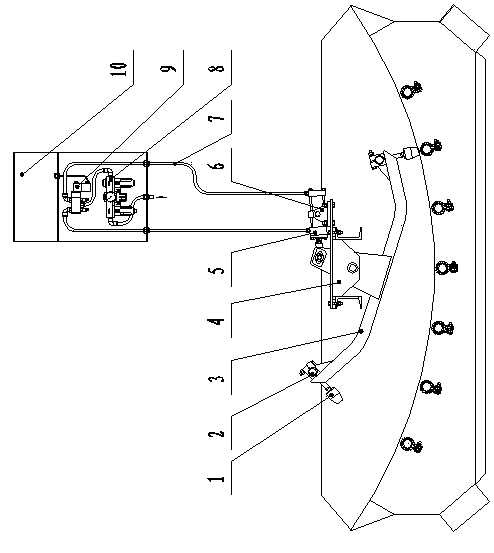

[0018] The invention discloses a swing type pneumatic striking device, which is composed of a striking head assembly 1, a striking rod 2, a rocker arm 3, a base 4, a cylinder 5 and an electric control box 10. The design idea of the present invention is: provide the rocker arm of the balance structure, use the intelligent instrument to control the cylinder, and the cylinder controls the rocker arm to realize the purpose of the invention.

[0019] See the specific structure figure 1 , install the intelligent instrument in the electric control box 10, the intelligent instrument is the intelligent digital timing controller OMRON (Omron) H5CX. The intelligent digital timing controller is connected with the electromagnetic reversing valve 9, and the electromagnetic reversing valve is a two-position five-way electromagnetic reversing valve 4V310-10-AC220V. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com