Glass processing platform and method for processing glass

A technology for processing platforms and glass, which is applied in the direction of workbenches, manufacturing tools, workpiece clamping devices, etc. It can solve problems such as inability to establish a vacuum in the stage area, irregular warping, and affecting equipment production efficiency and product quality stability. Achieve the effect of improving the success rate of adsorption and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

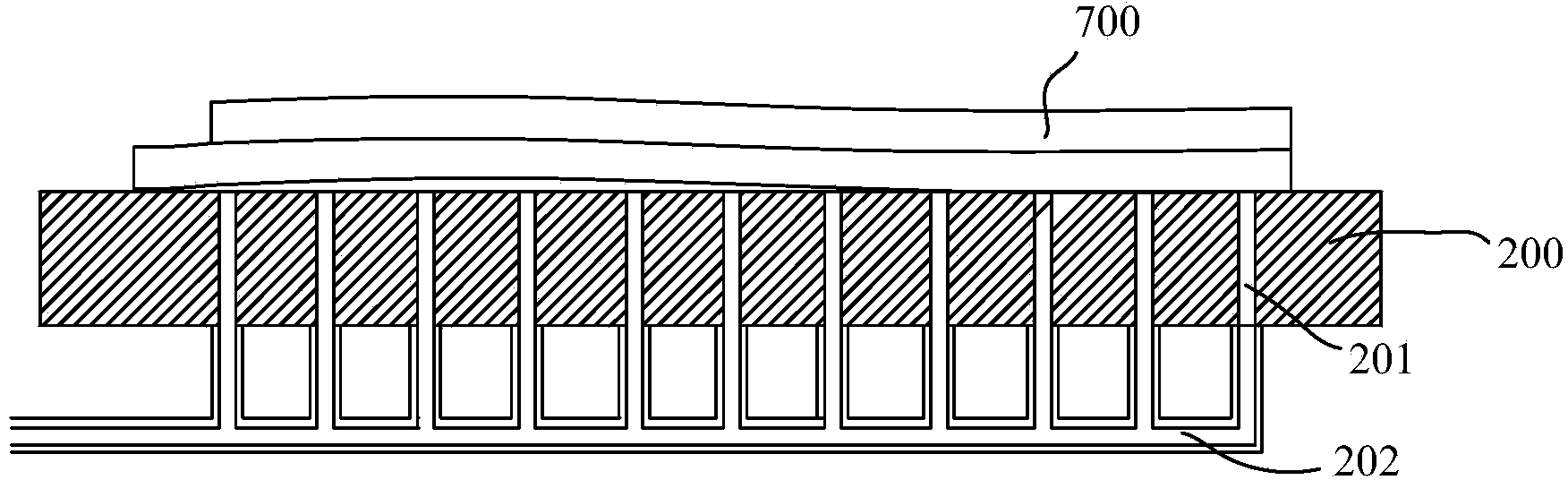

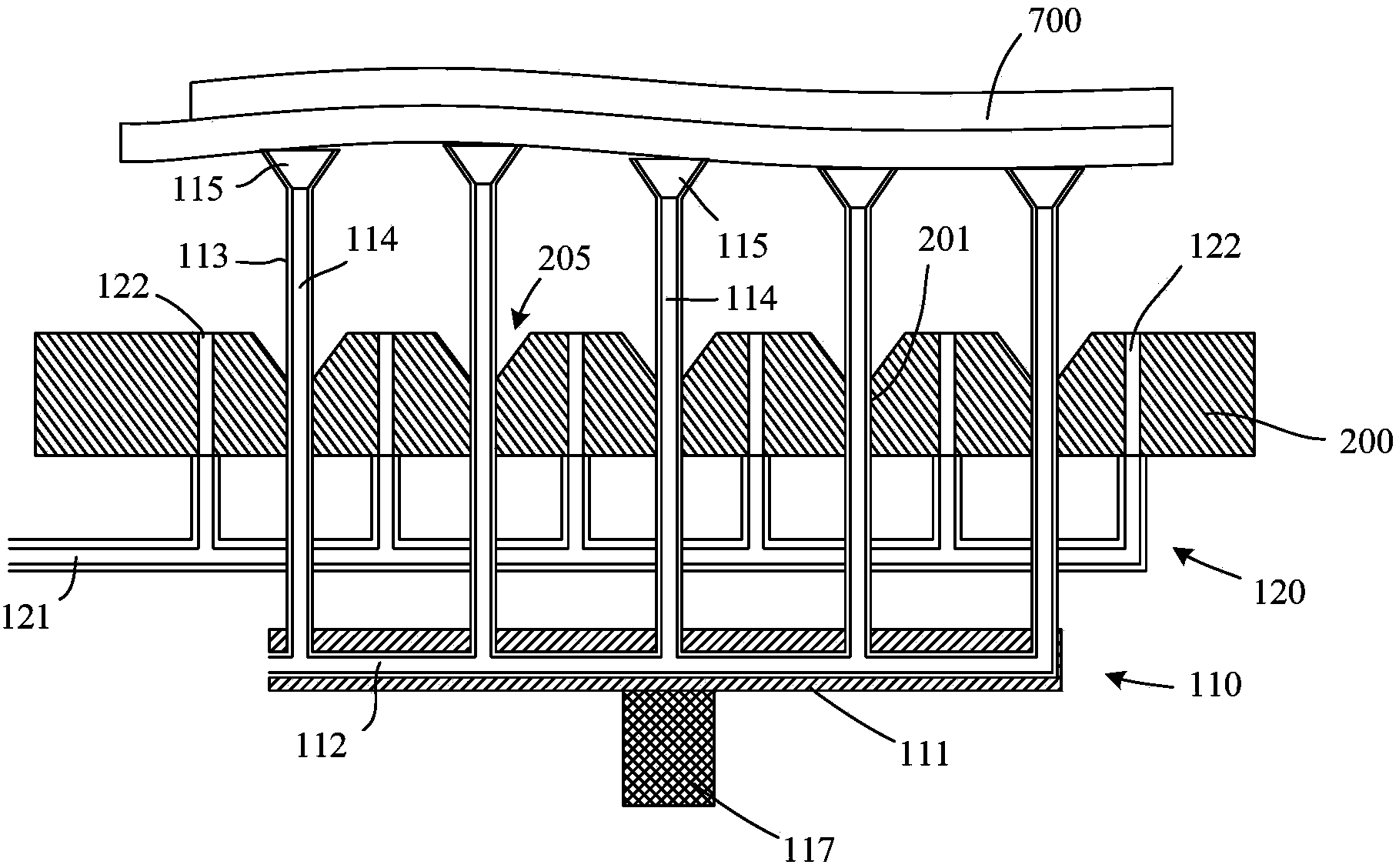

[0034] Such as image 3 Shown is a glass processing platform provided by this embodiment, which includes: a stage 200, a first vacuum adsorption device 110, and a lifting device 117; the stage 200 is used to directly carry the glass 700, and there are multiple a first through hole 201; the first vacuum adsorption device 110 includes a base 111, a plurality of support rods 113 with one end fixed on the base 111, a vacuum suction cup 115 arranged at the other end of the support rod, and the vacuum suction cups. 115 connected to the first vacuum line 114; the lifting device 117 is used to form a height difference between the suction surface of the vacuum chuck 115 and the carrying surface of the stage 200, and after the vacuum chuck 115 absorbs the glass 700 Eliminate the height difference so that the adsorbed surface of the glass is at the same level as the bearing surface of the carrier 200; the support rod 113 is arranged in the first through hole 201 and runs through the carr...

Embodiment 2

[0042] Such as Figure 5 As shown, the difference from Embodiment 1 is that the lifting device 117 of this embodiment is arranged on the carrier platform 200, and the formation and elimination of the height difference is to lower and lift the carrier platform 200 by the lifting device 117 to realise.

[0043] According to Embodiment 1 and Embodiment 2, the present invention can provide a glass processing method at the same time. Compared with the existing glass processing method, the difference is that the step S of glass adsorption on the processing platform is improved, specifically including the following step:

[0044] S1. Form a height difference between the carrying surface of the stage 200 and the adsorption surface of the first vacuum adsorption device 110 and absorb the glass 700; according to Embodiment 1, the height difference can be formed by lifting the first vacuum adsorption device 110, according to the implementation It can be known from Example 2 that the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com