Automatic conveying and packaging tube base flexible feeding and discharging mechanism

An automatic transmission and tube seat technology, which is applied in the direction of conveyor objects, auxiliary devices, transportation and packaging, etc., can solve the problems such as the difficulty of adjusting the stroke of the suction nozzle, so as to improve the success rate of adsorption, reduce the difficulty of stroke adjustment, and achieve reliable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

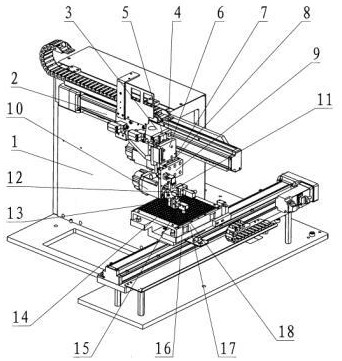

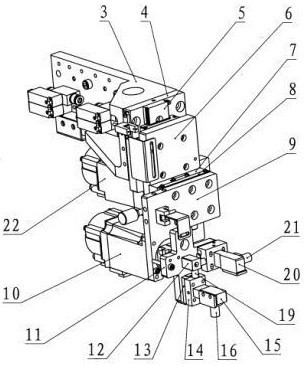

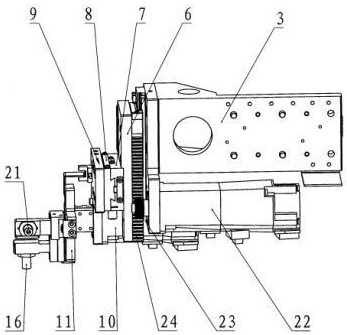

[0014] A tube seat flexible loading and unloading mechanism for automatic transfer packaging, including a support vertical plate 1, a mobile module 2 that moves along the horizontal front and rear direction is arranged on the top of the support vertical plate 1, and a module slide is provided on the mobile module 2. Block 3, on the front elevation of the module slider 3, a vertically moving guide rail installation plate 4 is fixedly arranged, on the front elevation of the up and down moving guide rail installation plate 4, an up and down moving guide rail 5 is arranged, and an up and down moving guide rail On 5, be provided with up and down moving slide block 6, on up and down moving slide block 6, be provided with rotating servo motor installation vertical plate 9, on rotating servo motor installation vertical plate 9, be fixedly installed with rotating servo motor 10, in rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com