Follow-up device of horizontal tail of airplane

A horizontal tail follow-up, aircraft technology, applied in aircraft parts, aircraft control, aircraft stability and other directions, can solve the problems of many movements, complex structure, large space occupation, etc., to achieve the effect of light weight, simple structure and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the drawings:

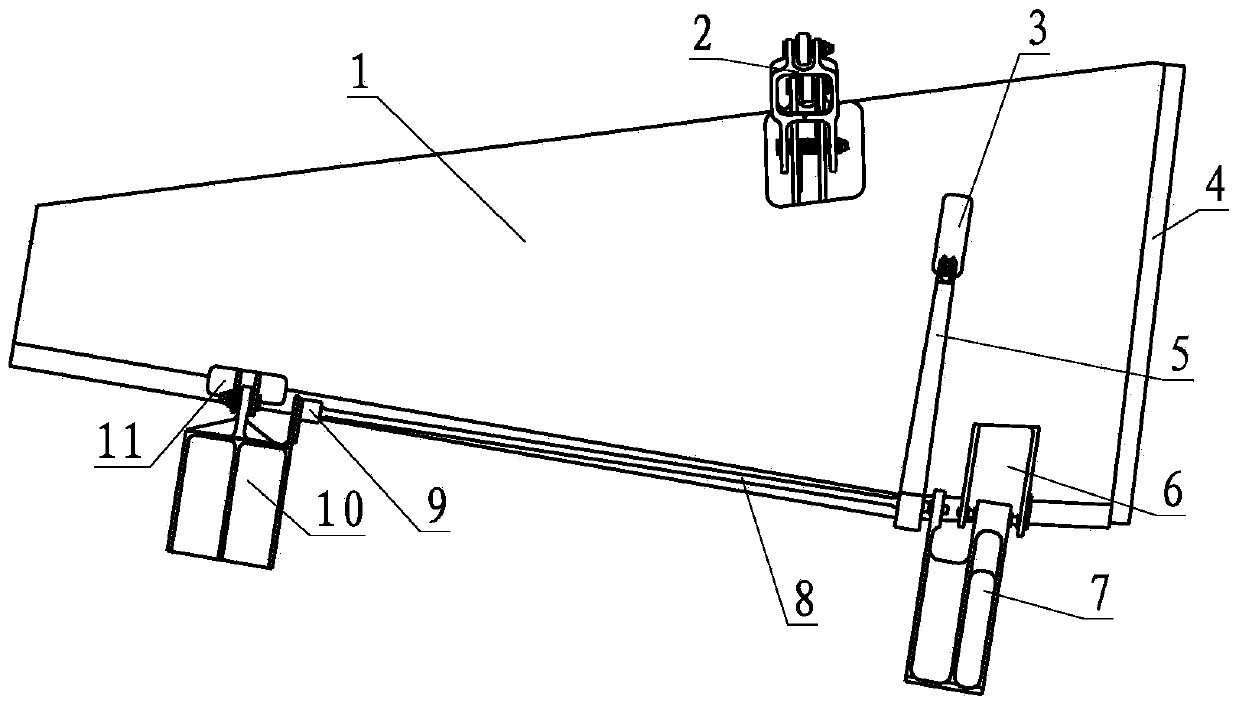

[0041] Reference figure 1 An aircraft flat tail follower, including a sealing plate 1, a roller trigger device 2, a torque arm support 3, a limit block 4, a torsion arm 5, a hinge 6, a hinge support 7, a torsion bar 8, and a torsion bar mounting support Seat 9, hinge support 10 and hinge 11.

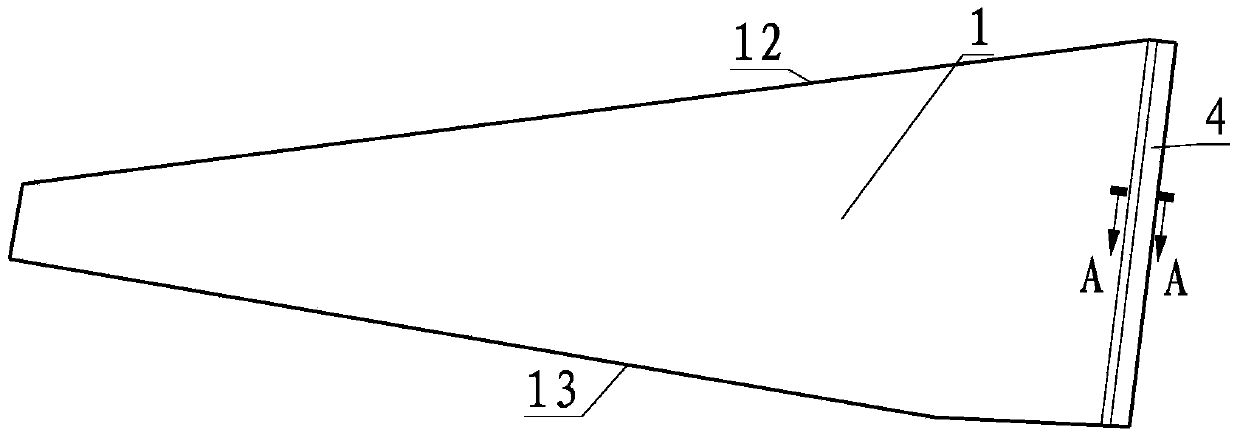

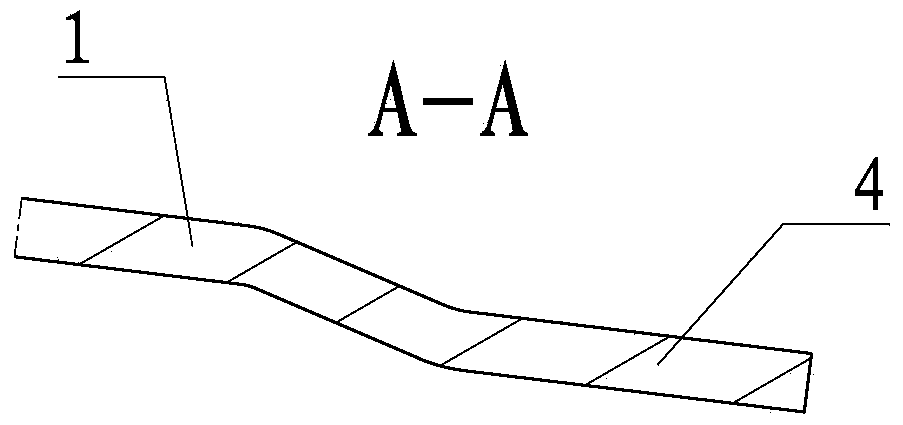

[0042] Reference 2, image 3 , The sealing board 1 is a flat structure, with a sinking structure at one end of the sealing board 1. The size and shape of the sealing board are determined according to the location of the sealing, and the sinking structure at one end of the sealing board is used as a limit block , The depth and length of the subsidence are compatible with the surrounding body; reference Figure 4 , The roller trigger device 2 includes a guide wheel 14, a guide wheel support 15, a driving wheel 16, a driving wheel support 17 and a spring 18. reference Figure 5 , The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com