Electromechanical actuator lubrication system for ram air turbine

A technology of actuators and gas turbines, which is used in auxiliary power equipment, aircraft transmissions, aircraft power transmission, etc., and can solve problems such as leakage, pressure increase, and fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

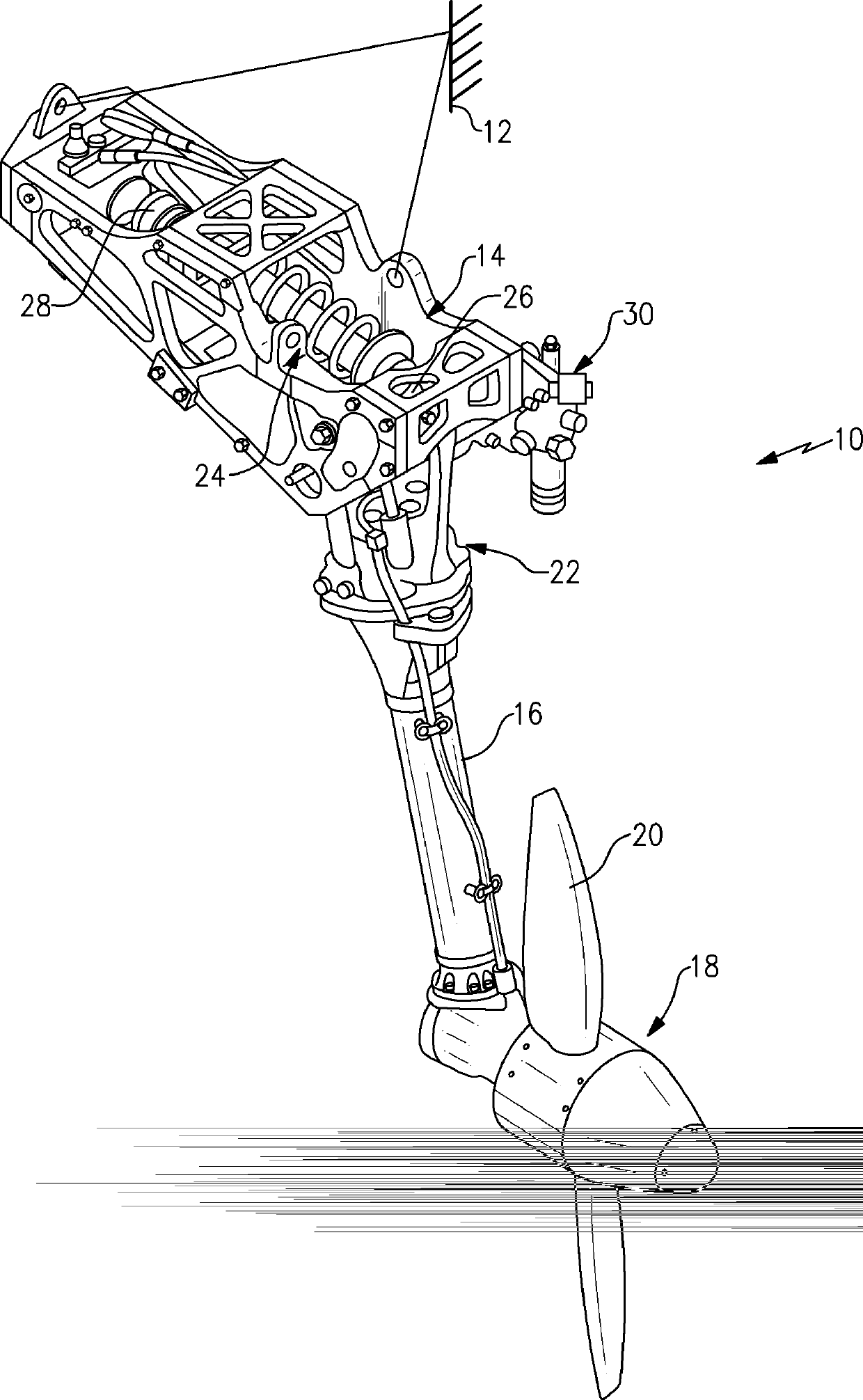

[0012] figure 1 RAT system 10 is shown secured to aircraft structure 12 by housing 14 . The housing 14 pivotably supports a strut 16 having a turbine 18 at one end. The turbine 18 includes blades 20 that impart rotational drive to, for example, a generator 22 and a hydraulic pump 30 . The actuator 24 is secured to the strut 16 at a first end 26 and to the housing at a second end 28 . Actuator 24 is shown in its deployed position.

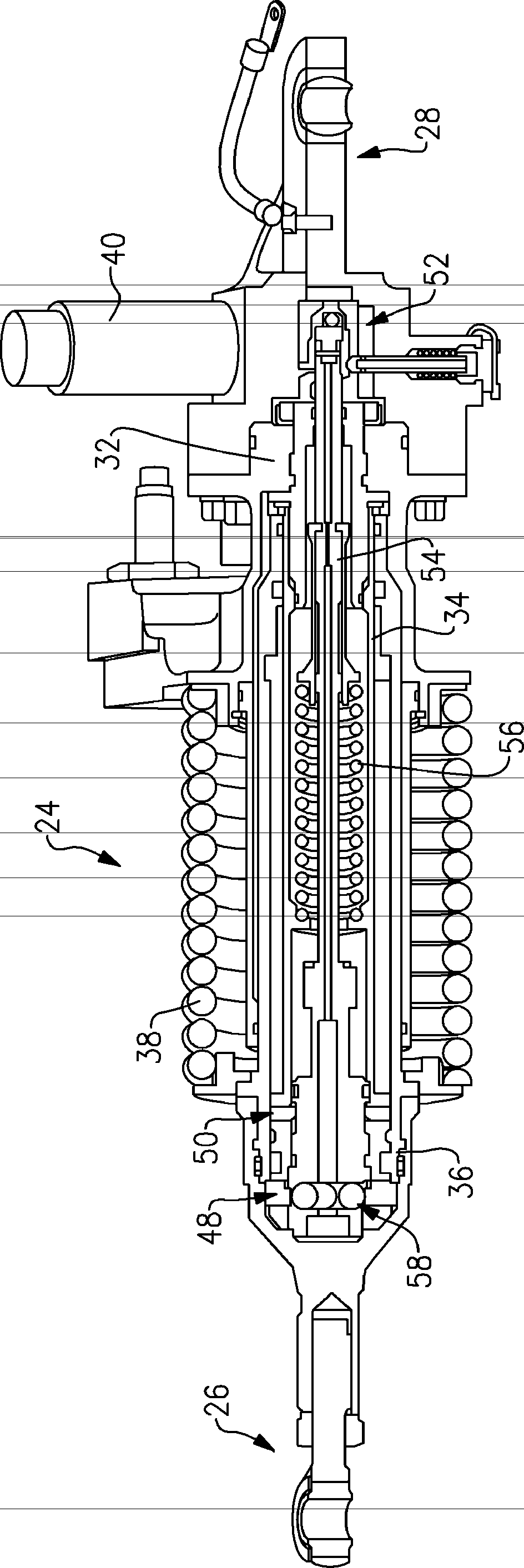

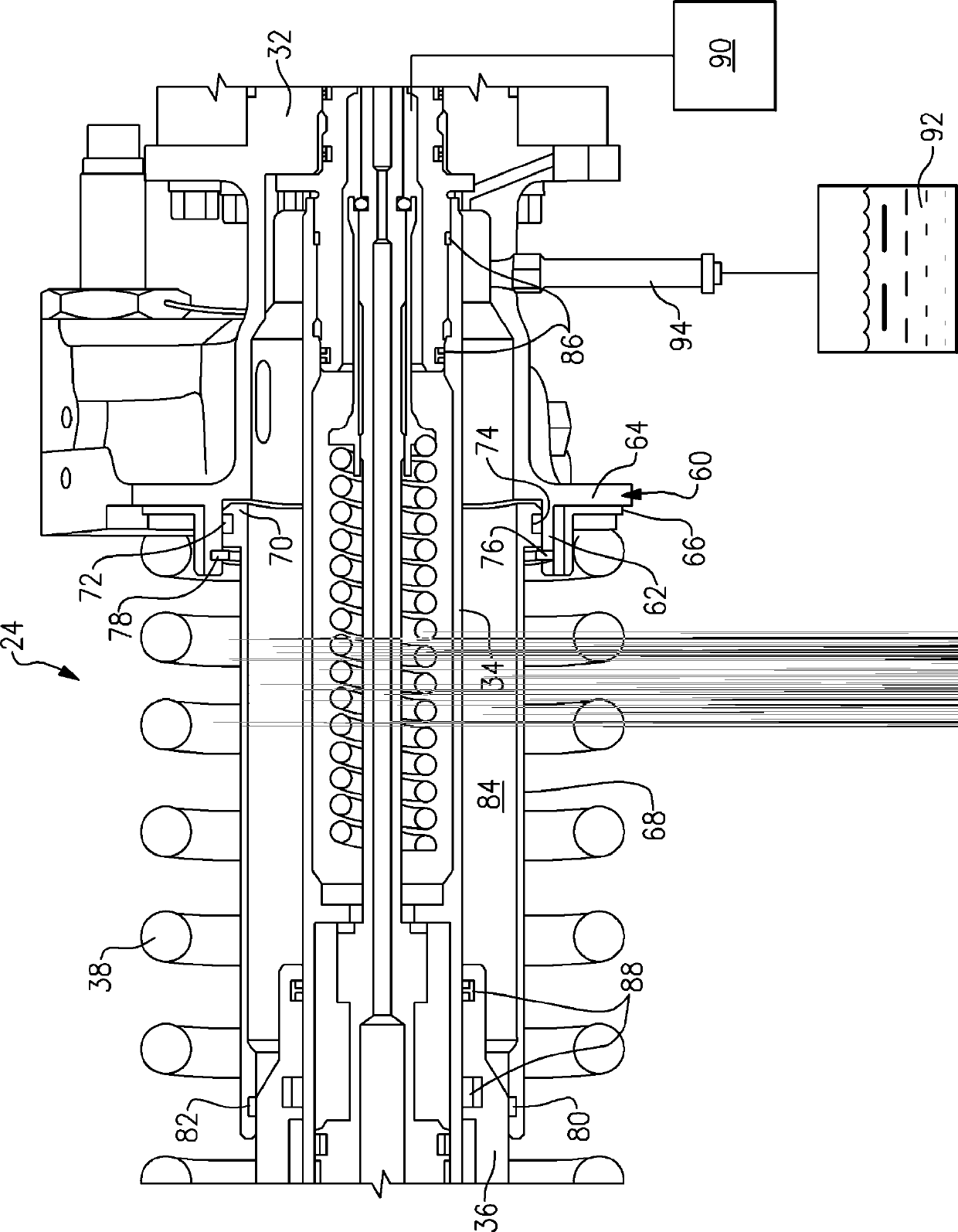

[0013] refer to figure 2 and image 3 , the actuator 24 comprises a housing 32 having a piston rod 34 and a cylinder 36 not attached to the housing 32, the piston rod 34 and the cylinder 36 being telescopically arranged relative to each other. Deployment spring 38 is arranged between housing 32 and cylinder 36, under compression, actuator 24 is in its retracted position, as figure 2 shown. A piston rod 34 is fixed to the housing 32 and a cylinder 36 is arranged to slide on the piston rod 34 .

[0014] The piston rod 34 supports an upper lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com