Engine cooling system and cooling method

A technology of engine cooling and oil cooler, which is applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems affecting engine emissions, low engine efficiency, energy waste, etc., to improve charging efficiency, increase output power, The effect of increasing the intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Its embodiment is described in detail below in conjunction with accompanying drawing.

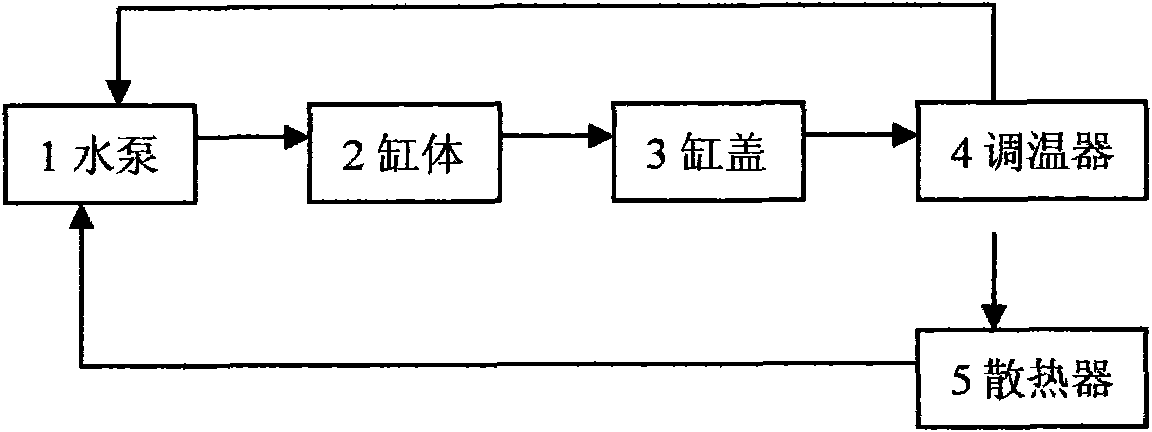

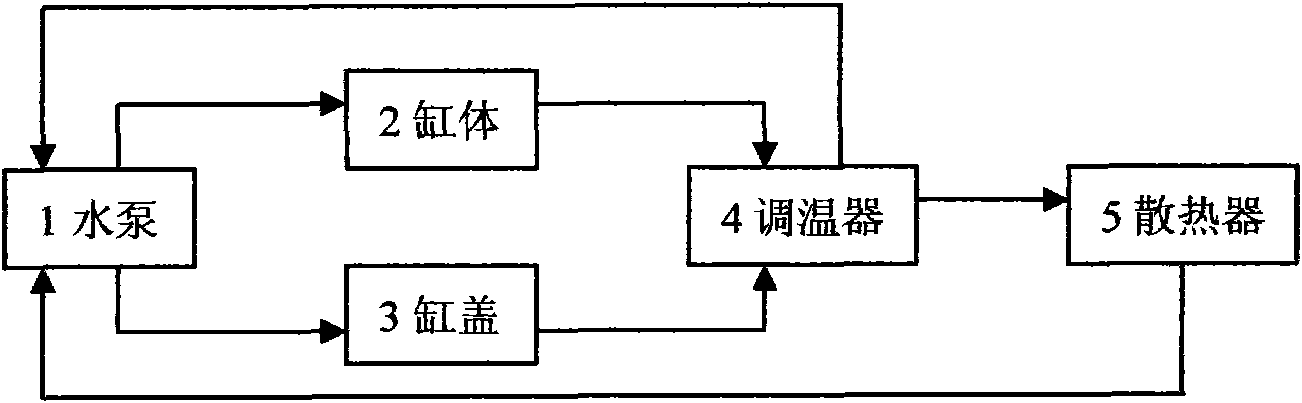

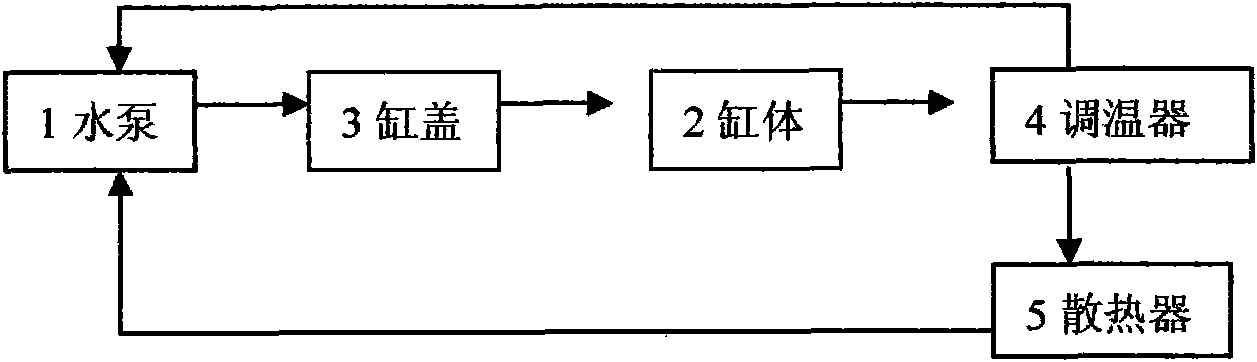

[0016] Figure 4 A visual representation of the water connection of the engine cooling system according to the embodiment of the present invention. When the engine starts, the water pump 1 starts to work, and the coolant is pressurized by the water pump 1 to start circulating. It first flows into the oil cooler 7, and then enters the cylinder head water jacket to cool the key areas of the cylinder head 3. The sheet circulation hole enters the water jacket of the cylinder body to cool the cylinder body 2 and then to the EGR (exhaust gas recirculation) cooler 8. When the temperature is normal, the paraffin in the thermostat 4 is solid, and the two-way water inlet of the radiator 5 In the state where the main valve is closed and the auxiliary valve is open, the main valve of the thermostat 4 is in a closed state, and the coolant from the radiator 5 of the water tank cannot enter the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com