Fishing net weight weaving machine

A weaving machine and net pendant technology, which is applied in the field of weaving machines, can solve problems such as unstable quality and low efficiency, and achieve the effects of stable finished product quality, improved production efficiency, and less chance of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below according to the drawings and embodiments.

[0026] The fishing net pendant knitting machine provided by the invention comprises a feeding device, a core adding device, a core wrapping device and a winding device.

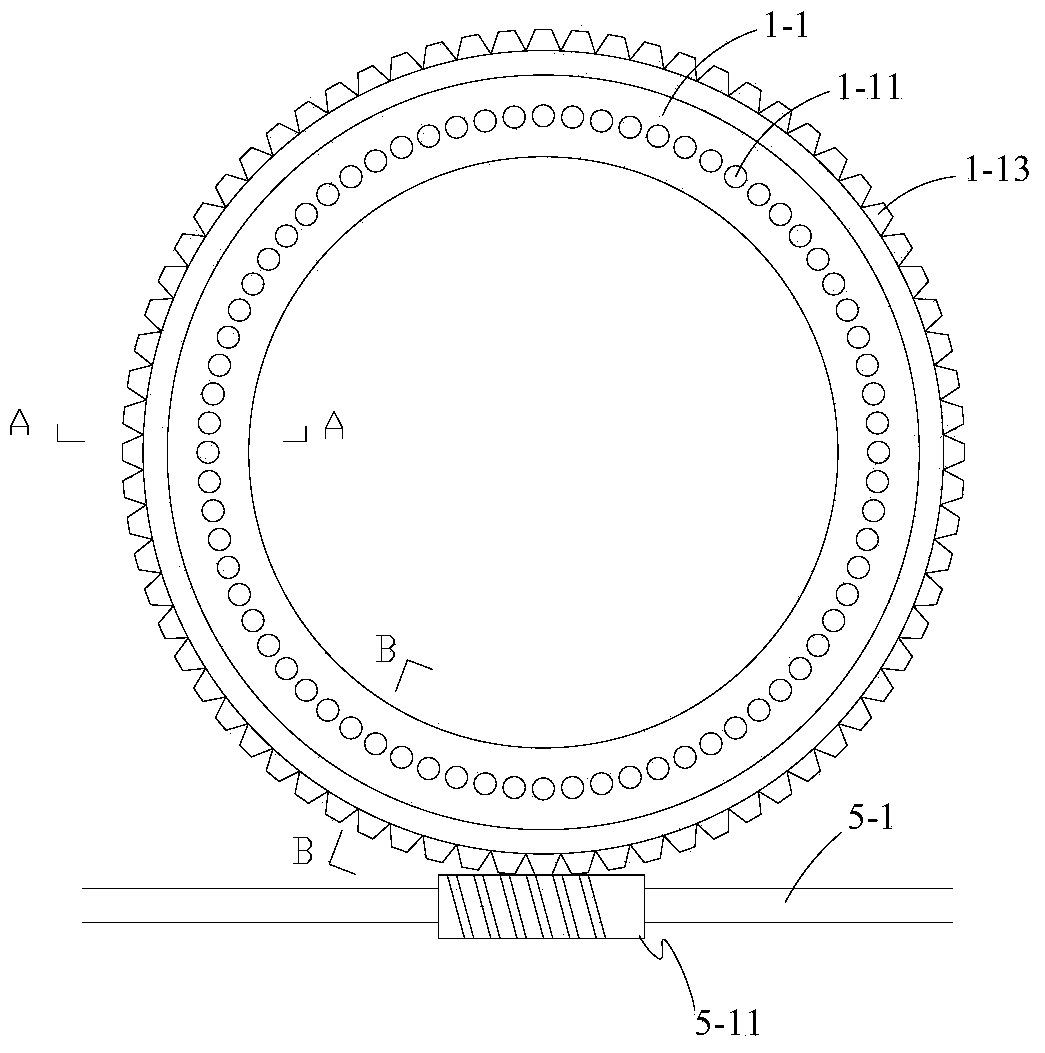

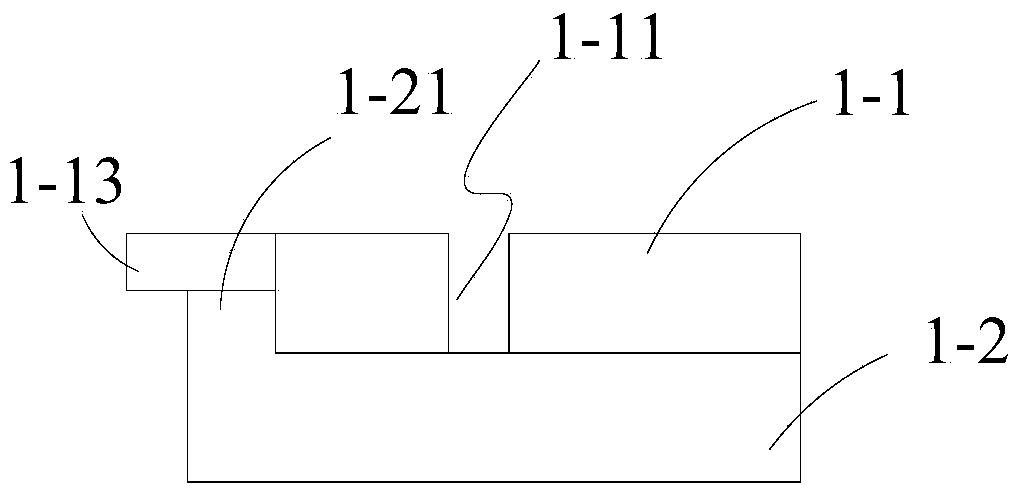

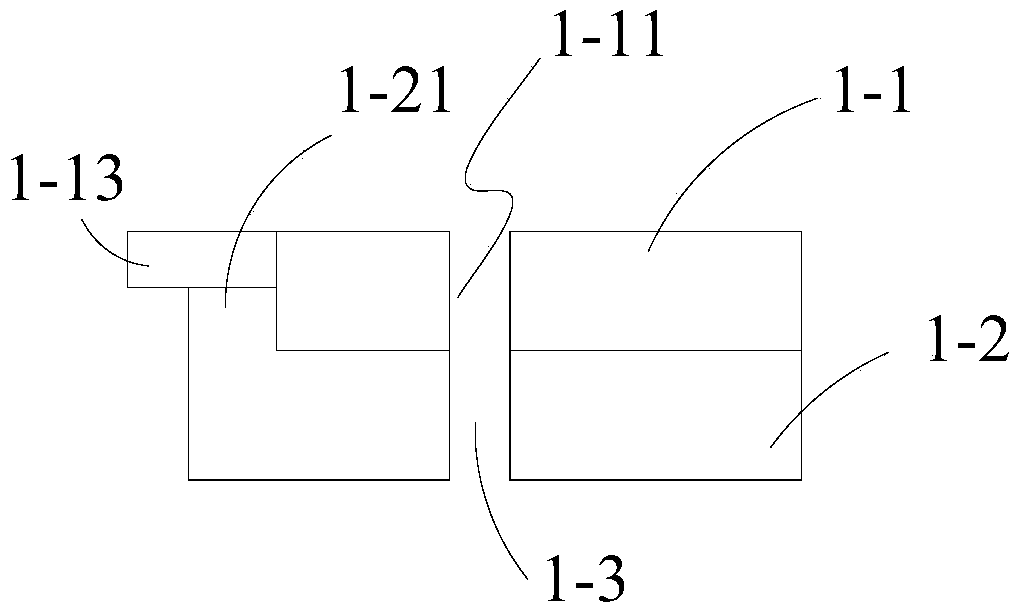

[0027] figure 1 It is a top view schematic diagram of the blanking device of this embodiment, figure 2 for figure 1 A-A sectional schematic diagram, image 3 for figure 1 B-B section schematic diagram, refer to figure 1 , figure 2 , image 3 , the blanking device includes a blanking tray 1-1, a blanking base 1-2, and a blanking port 1-3, wherein the blanking tray 1-1 is arranged on the blanking base 1-2, and the blanking tray 1-1 It can rotate around its center, and there is a circle of vertical passages 1-11 that can accommodate the iron core along the periphery of the blanking tray 1-1. The blanking port 1-3 is set at the edge of the blanking base 1-2, and The through channel 1-11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com