Diesel engine SCR (selective catalytic reduction) system control method based on urealysis efficiency

An SCR system and urea decomposition technology, applied in the field of diesel engine SCR system control based on urea decomposition efficiency, can solve the problems of leakage of ammonia gas injection, difficulty in determining the injection volume of urea aqueous solution, secondary pollution, etc., to reduce leakage and realize The effect of NOx high-efficiency conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

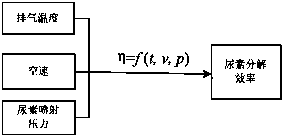

[0021] Embodiment 1: Determine the urea decomposition efficiency by parameters such as diesel engine exhaust temperature, space velocity, and urea aqueous solution injection pressure

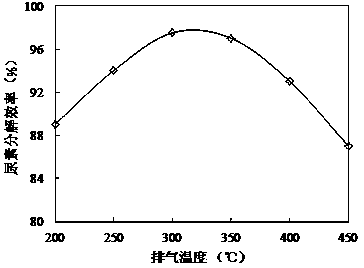

[0022] The present invention takes a diesel engine with a displacement of 7 liters as an example, uses simulation software to simulate and calculate the internal reaction of the SCR system of the diesel engine, and obtains the change of urea decomposition efficiency with the exhaust temperature under the condition that other influencing factors remain unchanged relationship, such as figure 1 shown.

[0023] Depend on figure 1 It can be seen that the urea decomposition efficiency increases first and then decreases with the exhaust temperature, and when the exhaust temperature is 350 °C, the corresponding urea decomposition efficiency can reach 97.5%.

[0024] Similarly, we can also obtain the relationship between the urea decomposition efficiency and the space velocity and the injection pre...

Embodiment 2

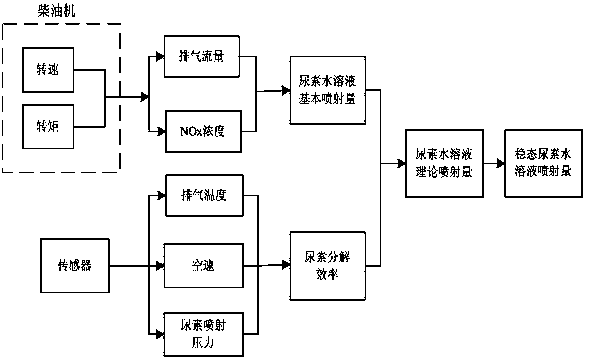

[0025] Example 2: Steady state control method for diesel engine SCR system based on urea decomposition efficiency

[0026] Based on the previous diesel engine SCR system control method, the present invention considers the influence of urea decomposition efficiency on the required urea aqueous solution injection quantity, so as to optimize the control method. Such as image 3 As shown, the specific implementation process of the method is as follows:

[0027] (1): When the diesel engine speed is 700rpm, 1100rpm, 1500rpm, 1900rpm, 2300rpm, and the load percentage is 20%, 40%, 60%, 80% and 100% respectively, the exhaust flow and exhaust gas flow rate of the diesel engine are obtained Static MAP plot of NO concentration. When the diesel engine speed is 1200rpm and the load percentage is 50%, according to the static MAP diagram of the diesel engine, the exhaust flow rate of the diesel engine under this working condition is 120g / s, and the concentration of NO in the exhaust gas i...

Embodiment 3

[0031] Embodiment 3: Correction of injection amount of aqueous urea solution under transient working conditions

[0032] The control methods in the above embodiments are typical steady-state control methods. However, when the engine is in a transient state, this method is difficult to accurately provide the actual required injection amount of urea solution for the engine.

[0033] Therefore, on the basis of the original control method, according to the NO x The change law of the conversion rate with the exhaust gas temperature and space velocity, etc., and the transient correction of the steady-state injection volume of the urea aqueous solution is carried out to obtain the actual urea aqueous solution injection volume required by the engine under each transient working condition, as shown in Figure 4 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap