Cylinder sleeve cooling structure of engine

A technology of engine cylinder and cooling structure, which is applied to engine components, machines/engines, cylinders, etc., can solve the problems of piston ablation, high cylinder liner temperature, and difficult control of cooling water flow state, so as to reduce the failure of parts and components. risk, improve the effect of local high temperature, improve the uniformity of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

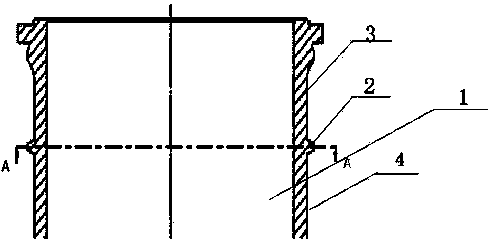

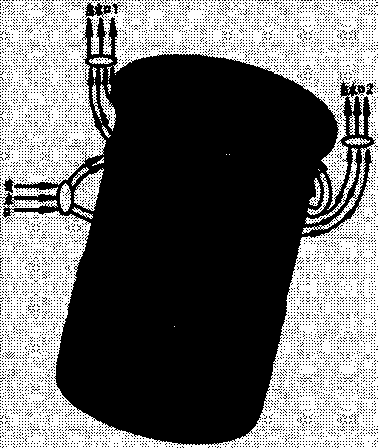

[0012] Such as figure 1 , figure 2 Shown, a kind of cooling structure of engine cylinder liner, it comprises cylinder liner 1 and the water flow guiding rib 2 that is arranged on cylinder liner 1, it is characterized in that cylinder liner 1 is an annular water chamber outside, and water flow guiding rib 2 guides said annular The water cavity is divided into the upper part 3 of the annular water cavity and the lower part 4 of the annular water cavity. The water flow guide rib 2 is a partially raised rib plate structure, and a gap is designed to guide the flow of cooling water at a position away from the water inlet and return ports.

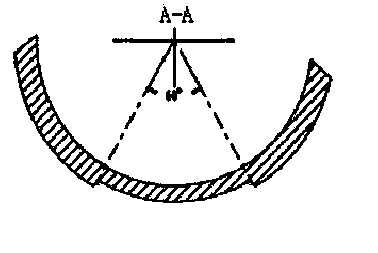

[0013] The water flow guiding rib 2 is designed with a notch with a central angle of 60 degrees at a position away from the water inlet and return ports.

[0014] The structure of the water flow guide rib 2 is spiral.

[0015] The structure of the water flow guide rib 2 is a multi-layer structure.

[0016] The working principle is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com