Low-noise fan for directional cooling

A low-noise, fan technology, applied in the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., can solve the problems of high fan noise and low cooling efficiency, and reduce rotational noise. , The effect of suppressing airflow vortex and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described

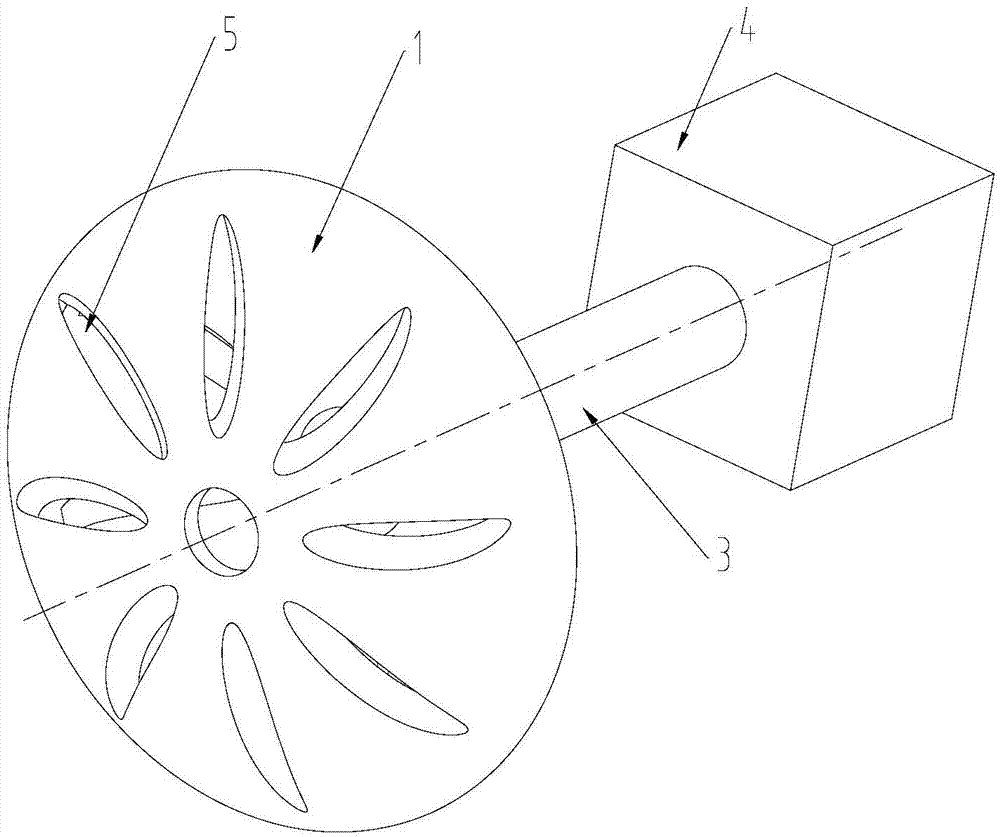

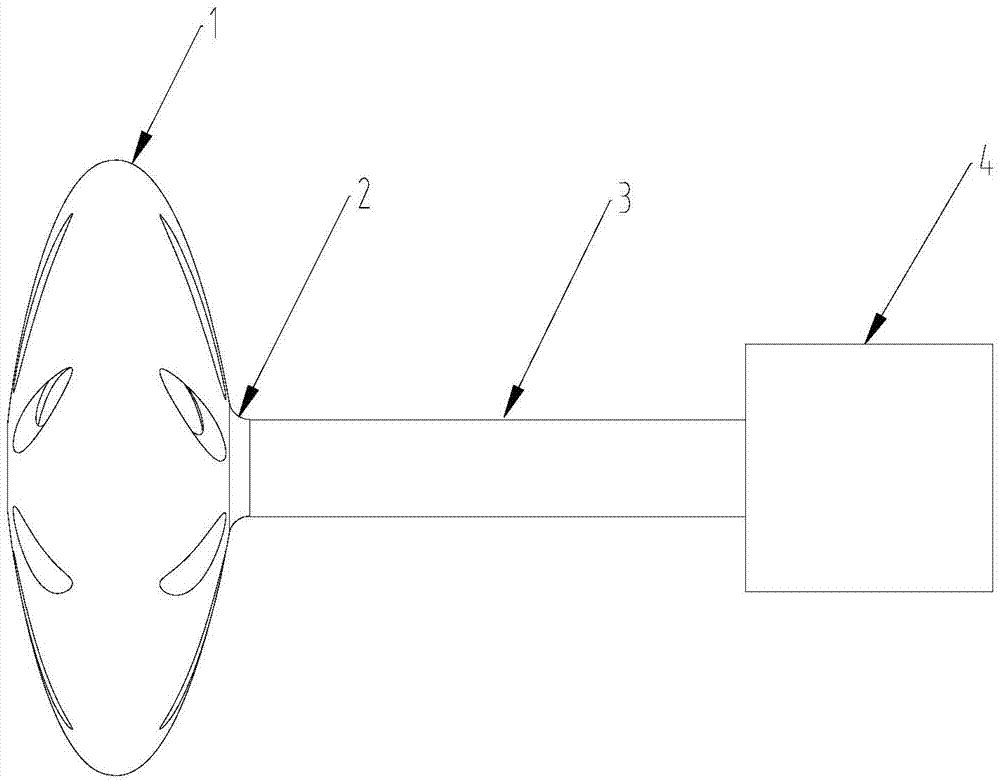

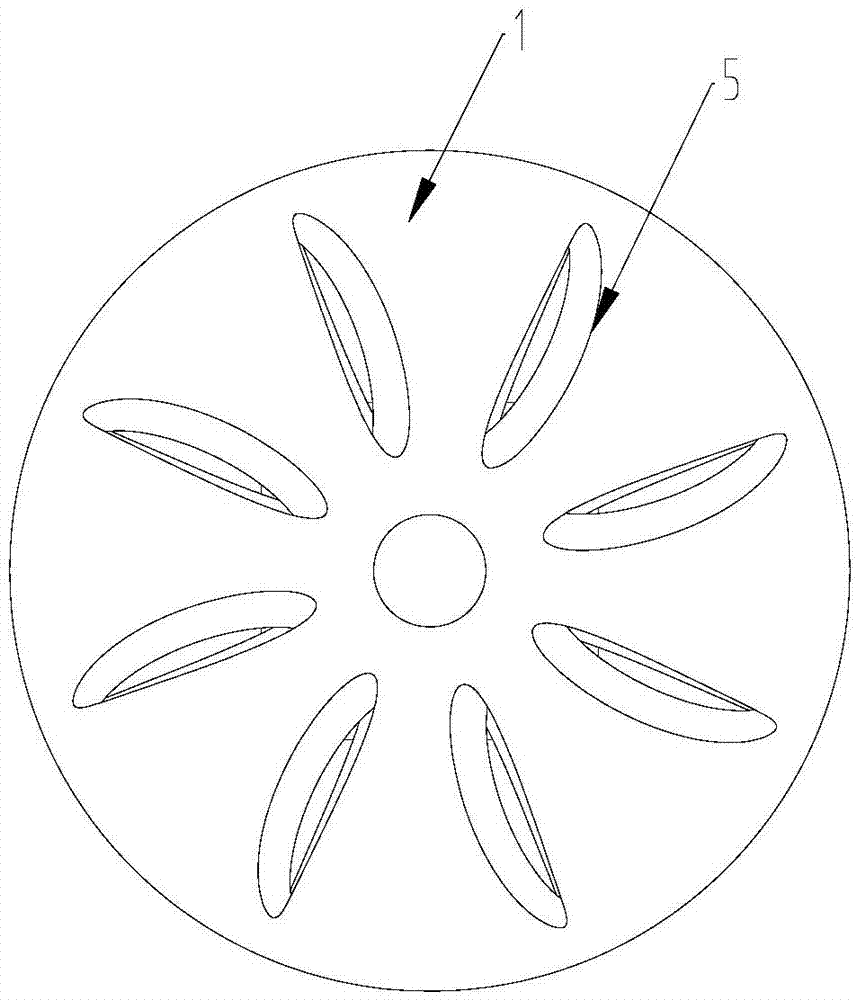

[0020] see Figure 1 to Figure 4 , a low-noise fan for directional cooling in the present invention, comprising a fan frame 1 adopting an integral spindle-shaped chamber structure, and a number of air-introduction slots 5 are uniformly opened along the center of the fan frame 1 in the circumferential direction to replace traditional fan blades, And the slotting direction of each air-introducing slot 5 matches the rotation direction of the low-noise fan; the outlet end of each air-introducing slot 5 communicates with the fan frame chamber 6 provided in the center of the fan frame 1; One side is provided with a transmission bearing and a linkage rod for connecting the motor to realize electric drive by connecting the motor, and the center position of the other side is connected to the ventilation pipe 3, and the ventilation pipe 3 is the air-inducing channel 7, and the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com