A closed cold pool system

A cold pool and closed cooling technology, applied in cooling/ventilation/heating transformation, modification of standard racks/cabinets, electrical components, etc., can solve problems such as transmission equipment closure, reduce maintenance costs, improve local cooling efficiency, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

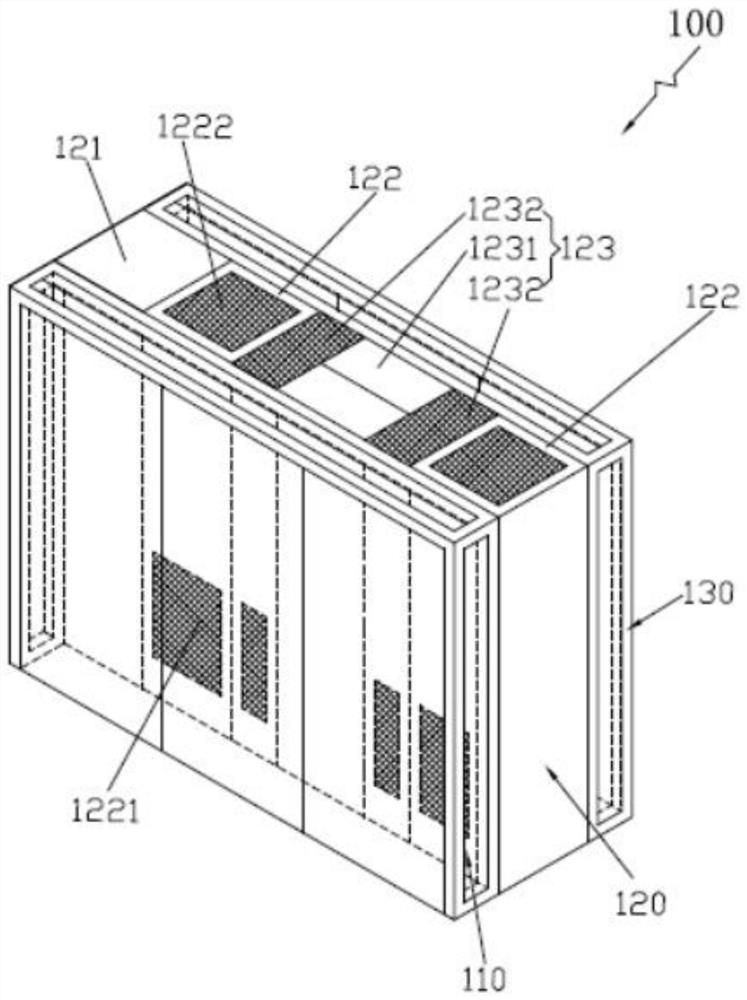

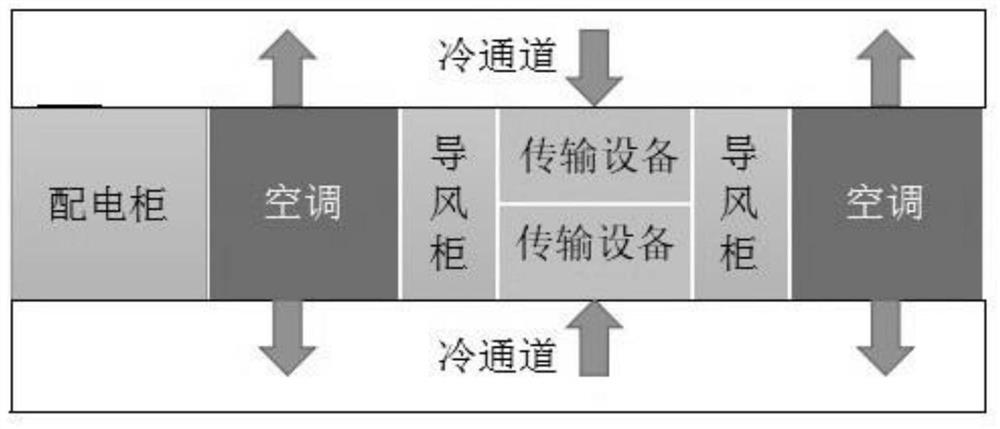

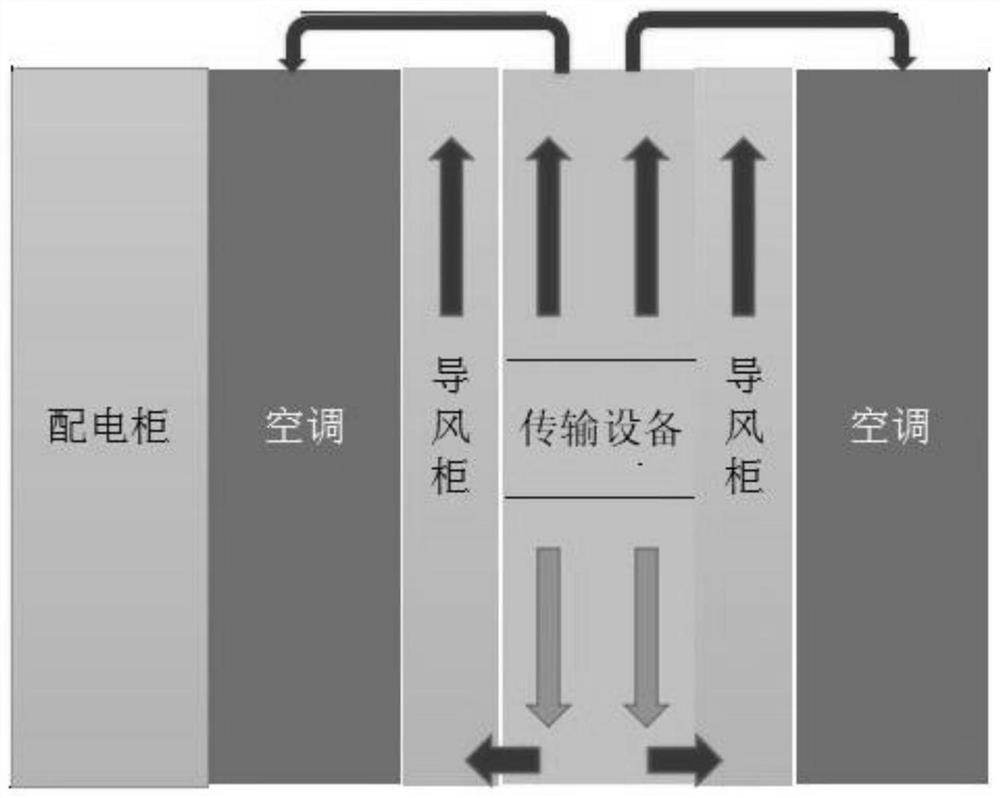

[0016] like figure 1 As shown, this embodiment provides an enclosed cold pool system 100 , and the enclosed cold pool system 100 includes a first enclosure assembly 110 , a cabinet assembly 120 and a second enclosure assembly 130 . The first enclosure assembly 110 is disposed on the front side of the cabinet assembly 120 , so that the front side of the cabinet assembly 120 forms a first closed cold aisle. The second closed assembly 130 is disposed on the rear side of the cabinet assembly, so that the rear side of the cabinet assembly 120 forms a second closed cold aisle. The cabinet assembly 120 includes power distribution cabinets 121, inter-row air conditioners 122, and main equipment units 123 arranged side by side. The room air conditioner 122 includes a front air supply port 1221, a rear air supply port (not shown) and a top air return port 1222. The front air supply port 1221 is connected to the first closed cold aisle, and the rear air supply port is connected to the se...

Embodiment 2

[0023] like Image 6 As shown, the second embodiment of the present invention provides a closed cold pool system. The difference between the closed cold pool system and the closed cold pool system 100 in the first embodiment is that the cabinet assembly includes a power distribution cabinet and a main cabinet group, and the main cabinet The lease includes two main equipment units and three inter-column air conditioners. A main equipment unit is set between two and two inter-column air conditioners, and the power distribution cabinet is located at either end of the main cabinet group. The airflow direction during normal operation is basically the same as the airflow direction of the closed cold pool system 100 in the first embodiment.

[0024]It can be seen that according to the configuration requirements of the actual equipment room, the closed cold pool can be used to seal multiple main equipment units. At this time, the cabinet components include the main cabinet group and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com