A car rear seat cushion clamping structure

A technology for rear seats and automobiles, which is applied in the direction of connecting members, shrinking connections, mechanical equipment, etc., can solve problems such as inability to solve buckle damage, and achieve the effects of small occupied space, reduced damage rate, and improved assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

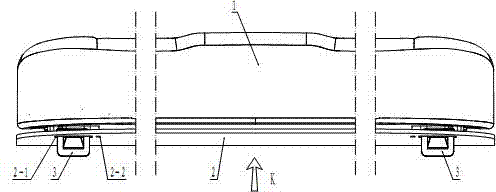

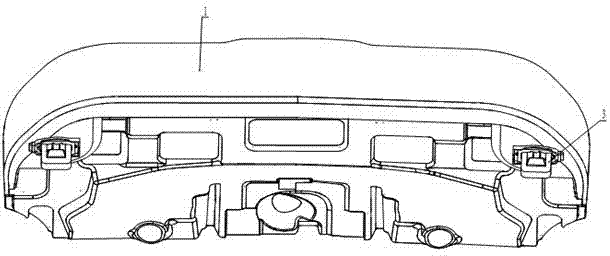

[0022] see figure 1 , figure 2 , image 3 , the present invention includes a snap 3 and a snap hole 2-1, the snap 3 is arranged symmetrically on the left and right, and they are snapped into the snap hole 2-1 opened by the body floor 2, and the snap 3 is formed by the snap body 3-1 is composed of a buckle pressing piece 3-2. The buckle body 3-1 is fixed on the bottom surface of the rear seat cushion 1 of the automobile by means of mounting bolts 3-3. It is connected with the buckle pressing piece 3-2. Fitting.

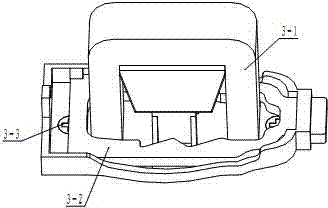

[0023] see Figure 4 , Figure 5 , Image 6 , the buckle body 3-1 of the present invention is provided with a snap ring 3-1-1, a spring piece 3-1-2, an oblique push block 3-1-3, a bridge plate 3-1-4, and an elastic base 3-1- 5 and the positioning card 3-1-6, the snap ring 3-1-1 is an inverted "U"-shaped structure, which is fixed on the elastic base 3-1-5, the elastic piece 3-1-2, oblique The push block 3-1-3 and the bridging plate 3-1-4 include two symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com