Automotive Clutch Bearings

A clutch and bearing technology, which is applied in the field of clutch bearings for vehicles, can solve the problems of loss of sealing lip interference, shortening of bearing life, torque loss, etc., and achieve the effects of avoiding impact, shallow contact position, and ensuring life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

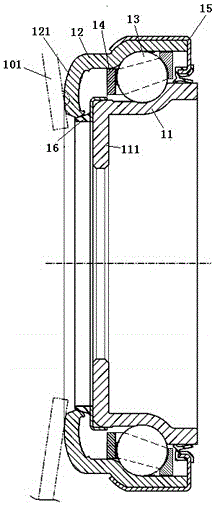

[0027] see figure 1 , shows the vehicle clutch bearing of the present invention.

[0028] The vehicle clutch bearing includes an inner ring 11 , an outer ring 12 , a plurality of balls 13 rotatably provided between the inner and outer rings, and a cage 14 rotatably holding the balls 13 .

[0029] A first sealing unit 15 is provided between the inner ring 11 and the rear ends of the outer ring 12 , and a second sealing unit 16 is provided between the inner ring 11 and the front ends of the outer ring 12 .

[0030] A radially inwardly extending inner ring ridge 111 is formed on one side of the inner ring 11 , and a radially inwardly extending outer ring ridge 121 is formed on one side of the outer ring 12 . The axial outer side of the outer ring ridge 121 is resisted by the diaphragm spring 101 , and the second sealing unit 16 is disposed between the inner ring ridge 111 and the outer ring ridge 121 .

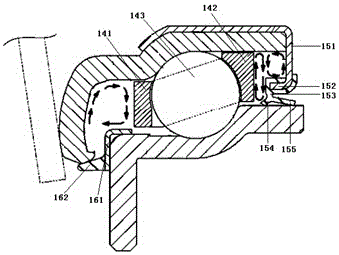

[0031] see figure 2 , the cage 14 includes a front retainer 141 and a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com