Anti-gear-skipping gear reversing machine

A reverse gear and anti-jump technology, applied in the direction of instruments, controlled components, mechanical control devices, etc., can solve the problems of inconvenient operation, prone to skipping, poor reliability, etc., to achieve the effect of easy operation and avoid skipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

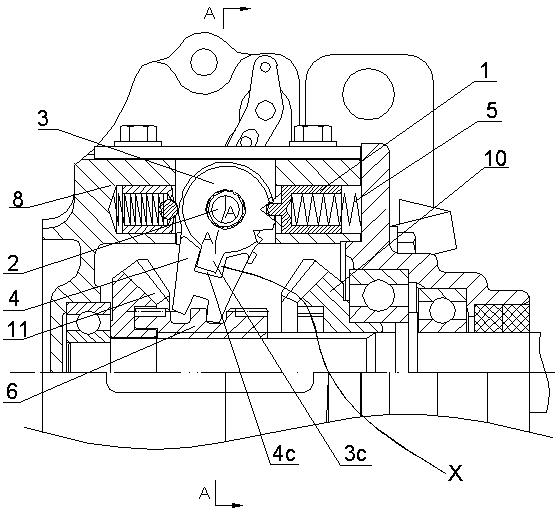

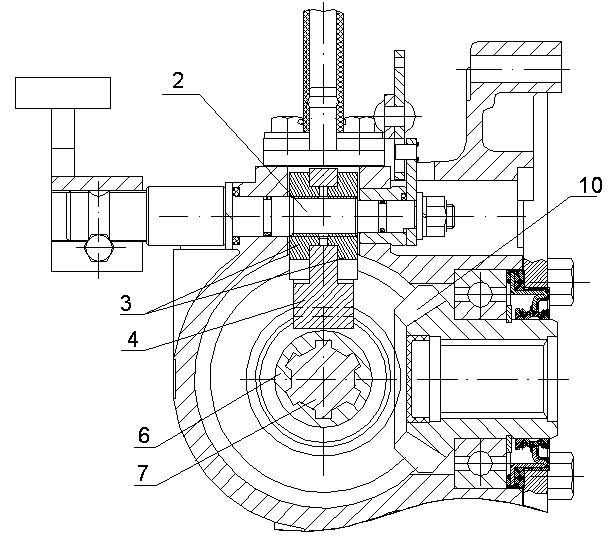

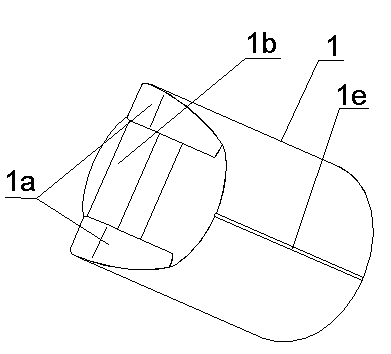

[0018] like figure 1 , figure 2 Shown, a kind of anti-jump gear reverse gear, contains reverse gear housing 8, shift shaft 2, shift fork 4, input gear 9, forward gear 10, reverse gear 11, two-way combination gear 6 and output shaft 7. One end of the shift fork 4 matches the circumferential annular boss or the circumferential annular groove on the two-way combined gear 6. The two-way combined gear 6 can be axially moved on the output shaft 7 through the key, and the shift fork 4 can drive The two-way combined gear 6 moves axially on the spline shaft section of the output shaft 7 . The forward gear 10 and the reverse gear 11 are vacantly sleeved on the output shaft 7 and located on both sides of the two-way combination gear 6. The input gear 9 meshes with the forward gear 10 and the reverse gear 11 at the same time. When the two-way combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com