A special lamp structure for water jet loom

A water-jet loom and special lamp technology, which is applied in the field of lamps and lanterns, can solve the problems of inconvenient disassembly and maintenance, complex internal structure, troublesome installation and disassembly, etc., and achieve the effect of good lighting effect, simple structure and convenient components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

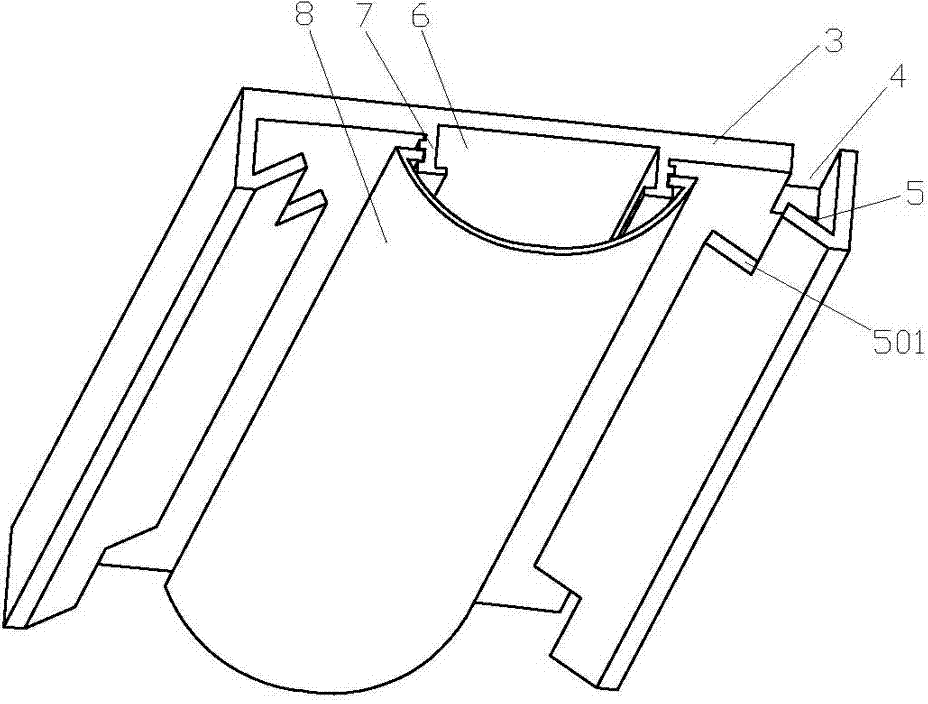

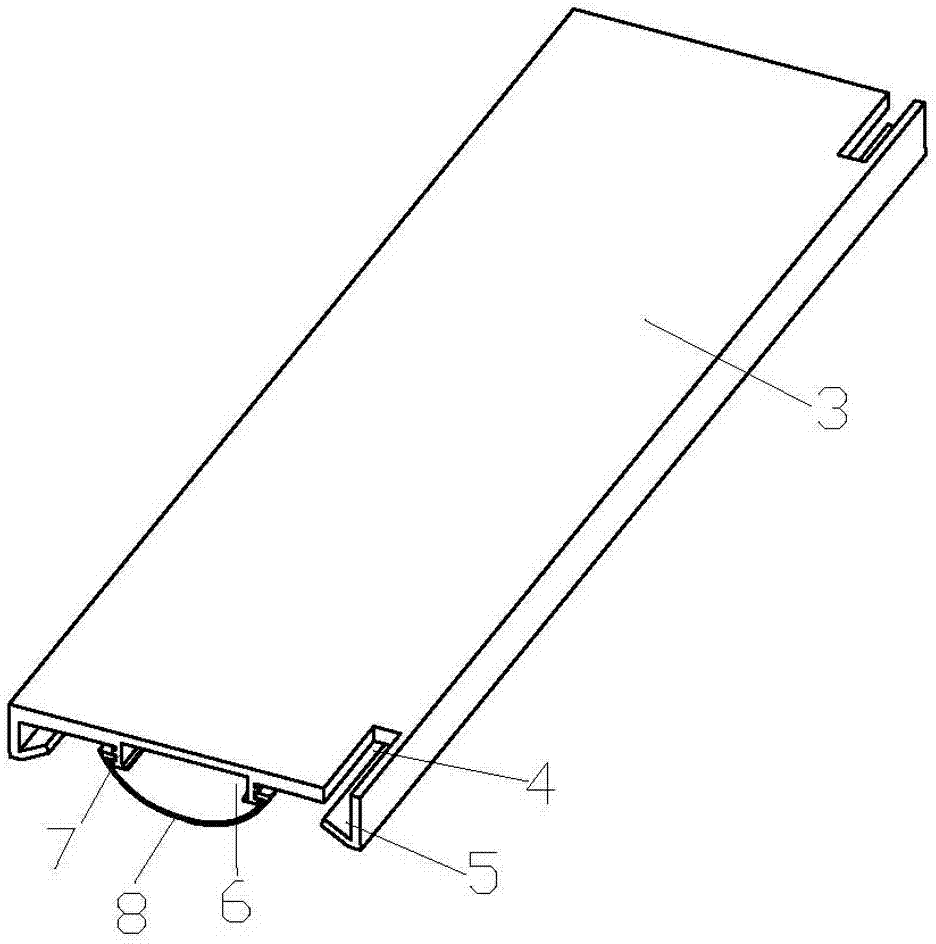

[0021] Such as figure 1 , 2 As shown, a special lamp structure for a water jet loom includes a lamp cover and a lamp body located inside the lamp cover. Side plates 7 are arranged on both sides of the insertion slot 6 , and light uniform plates 8 are arranged along the outer walls of the two side plates 7 . The lamp body is installed on the base plate 3 arranged in the lamp cover, and the two ends of the base plate 3 are provided with wire traction grooves 4 near the sides, which can only be opened on one side, and the wires can be placed on one side. Due to its structure Smaller has less impact on the balance of the overall structure, so it can be designed in this way, of course, it can also be opened on both sides to make the structure more balanced. The side of the substrate 3 along the length direction is also provided with a wire guide cavity 5, the wire guide cavity 5 is formed by extending and folding the side of the substrate 3, preferably both sides are provided w...

Embodiment 2

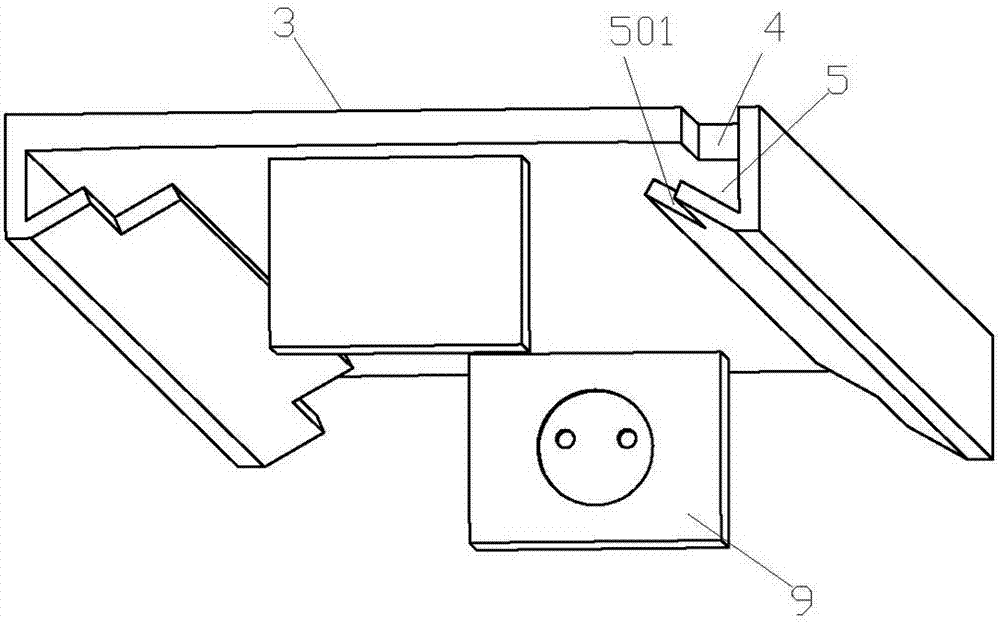

[0024] Such as image 3 As shown, a special lamp structure for a water jet loom includes a lamp housing and a lamp body located inside the lamp housing. The lamp body is installed on the base plate 3 arranged in the lamp housing. The two ends of the base plate 3 are provided with wire drawing grooves 4 near the sides, and the base plate 3 is also provided with a wire guide cavity 5 along the side of the length direction. The wire guide cavity 5 is formed by extending and folding the side of the substrate 3 . The substrate is provided with reinforcing notches 501 at both ends of the wire guide cavity 5 . The wire guiding groove 4 is covered by the wire guiding cavity 5 and the reinforcing notch 501 and the wire pulling groove 4 do not overlap on the orthographic projection of the substrate 3 . The substrate 3 is an iron plate. The surface of the substrate 3 is coated with an aluminum film.

[0025] A ballast should also be installed on the base plate 3, the ballast is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com