A Secondary Cooling Water Branch System Equipped with Width Cutting Branch

A branch and water technology, applied in the field of metallurgical continuous casting equipment and control, can solve the problem of uneven cooling of the corner of the billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

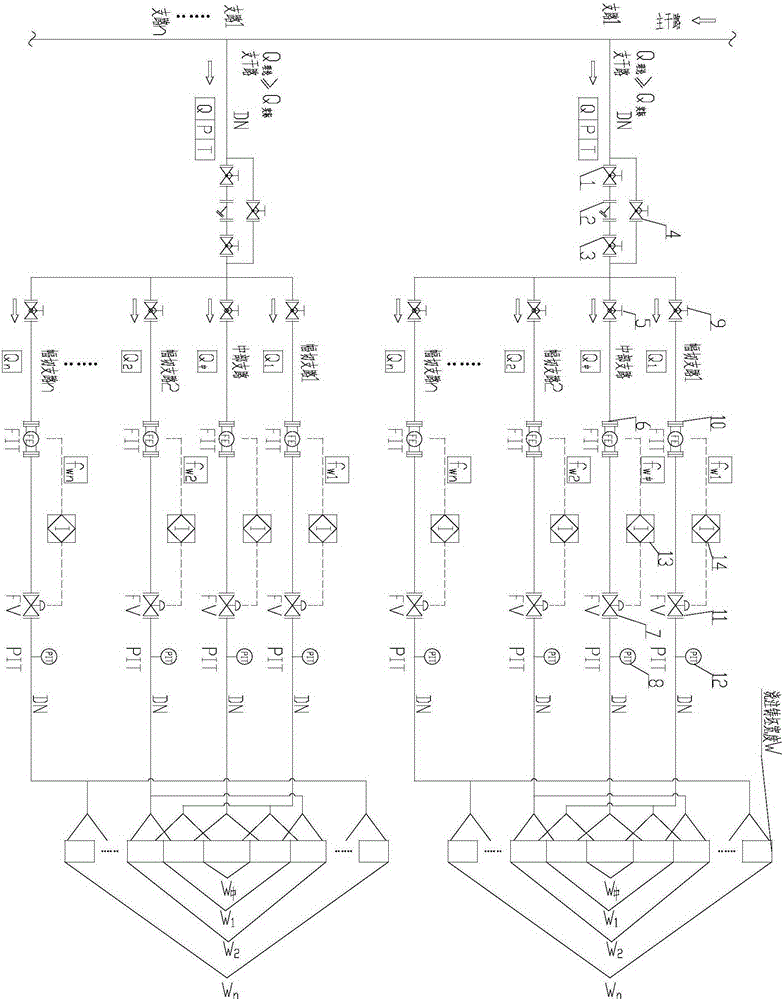

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] A secondary cooling water branch system equipped with a cutting branch, including at least one branch, each branch has the same configuration, each branch contains a branch trunk, and a middle branch is connected in parallel downstream of the branch trunk Road and at least one cutting branch; the configuration of each cutting branch is the same;

[0015] The branch road is equipped with a first manual ball valve 1, a Y-row filter 2 is arranged downstream of the first manual ball valve 1, a second manual ball valve 3 is arranged downstream of the Y-row filter 2, and the upstream of the first manual ball valve 1 and the second A bypass is set downstream of the manual valve 3, and a third manual ball valve 4 is arranged on the bypass;

[0016] The middle branch is equipped with a fourth manual ball valve 5, a first electromagnetic flowmeter 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com