Spinneret

A technology of spinneret and spinneret, which is applied in the field of spinning, can solve the problems of uneven fiber cooling strength, fiber moisture absorption, increase in fiber strength and elongation unevenness, and affect the tensile properties of primary fibers, etc., to achieve fiber moisture absorption. Uniformity, reduced strength and elongation unevenness, and uniform cooling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

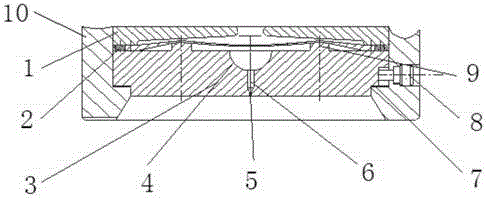

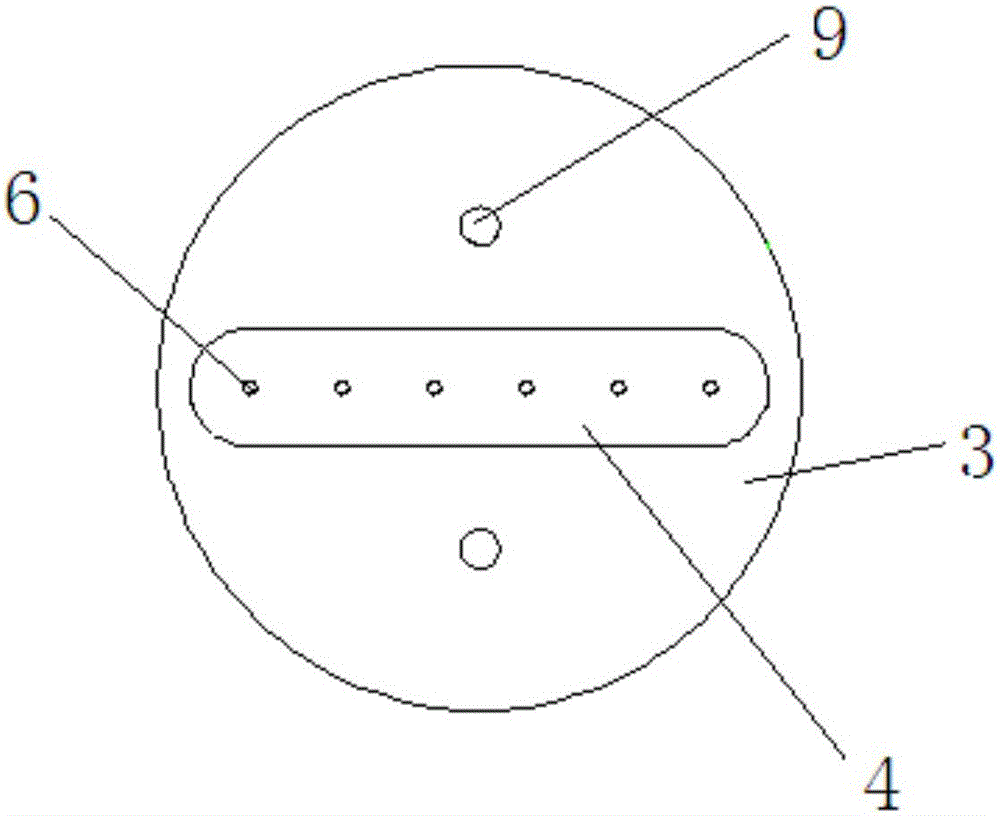

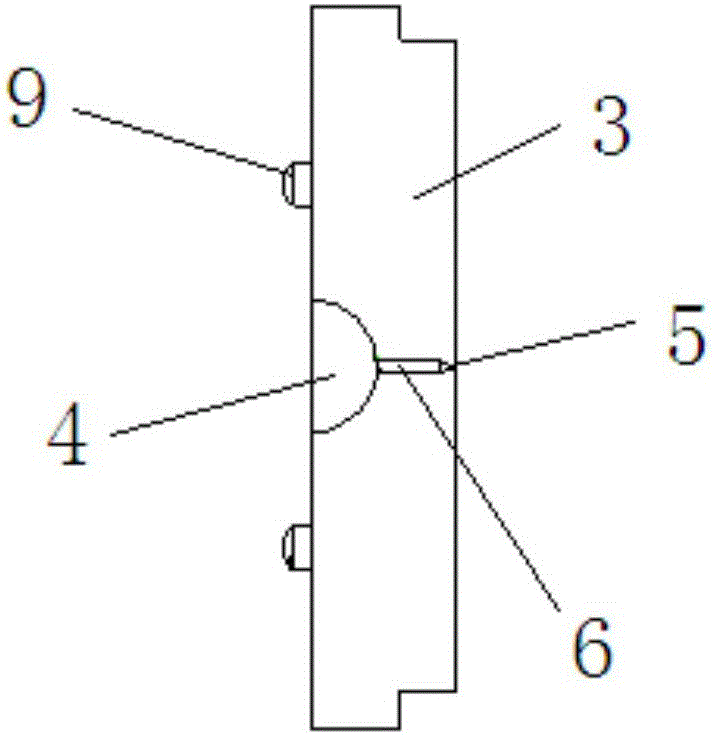

[0018] see Figure 1-3 , a spinneret provided by the embodiment of the present invention is fixed on the component body 10; the spinneret includes: a plate body 3, a flow dividing device, a filtering device and a flow guiding device.

[0019] The plate body 3 is fixedly connected with the assembly body 10 .

[0020] The distribution device is connected with the plate body 3 .

[0021] The filter device is arranged on the flow distribution device.

[0022] The deflector is arranged in a straight line inside the plate body 3 .

[0023] Wherein, the melt enters the plate body 3 through the filter device, and then sequentially enters the flow guide device for spinning.

[0024] The structure of the split device is introduced in detail.

[0025] The distribution device includes: a distribution column 9 .

[0026] The splitter column 9 is connected with the plate body 3 . The upper end of the splitter column 9 is spherical. The lower end of the splitter column 9 is in interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com