Chilling disc for cooling, orienting and solidifying liquid metal

A liquid metal cooling and directional solidification technology, applied in the field of chilled plate, can solve the problems of large temperature fluctuation, uneven cooling intensity, large temperature fluctuation of the chilled plate, etc., and achieve the effect of uniform cooling intensity and balanced temperature of cooling medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

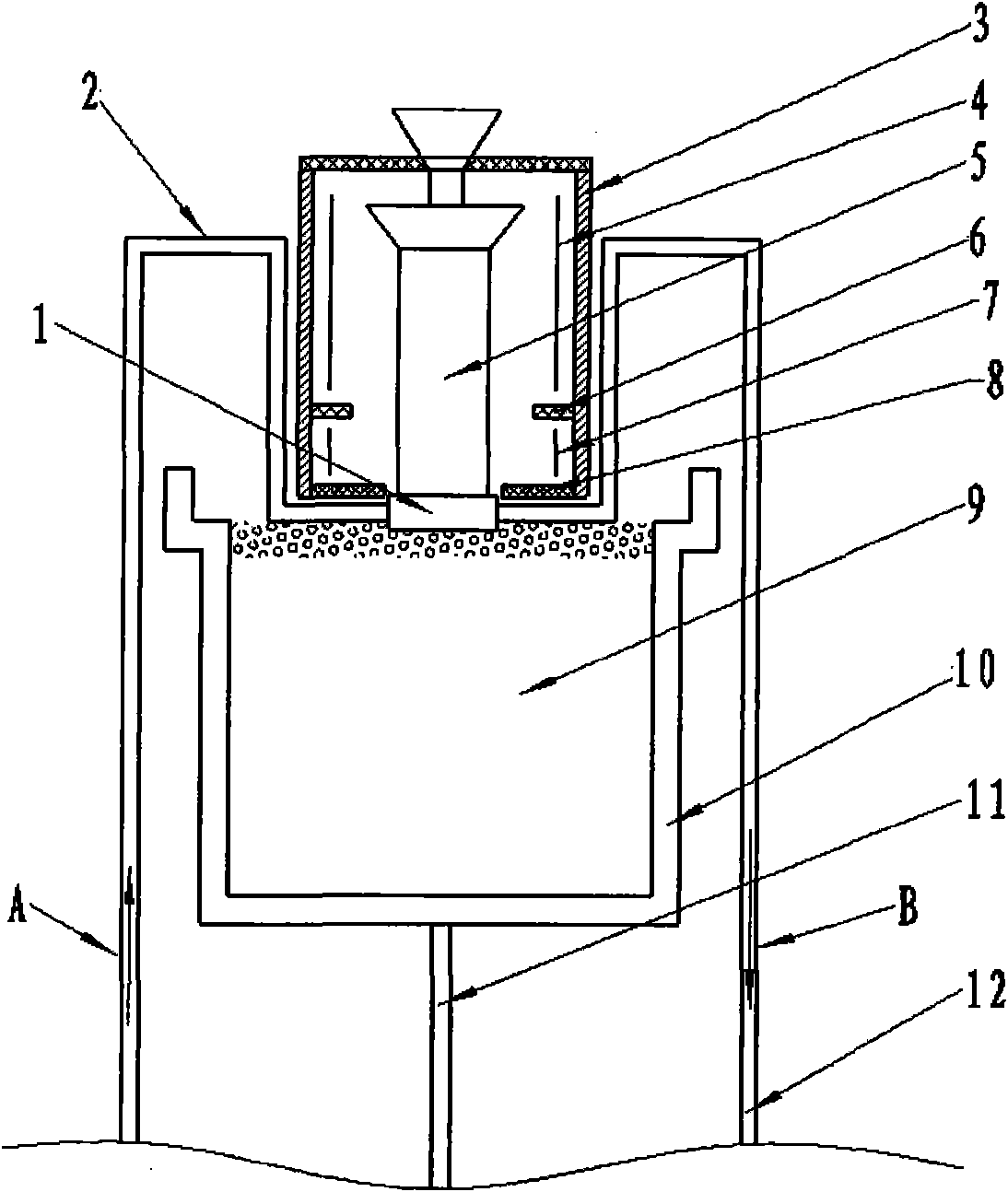

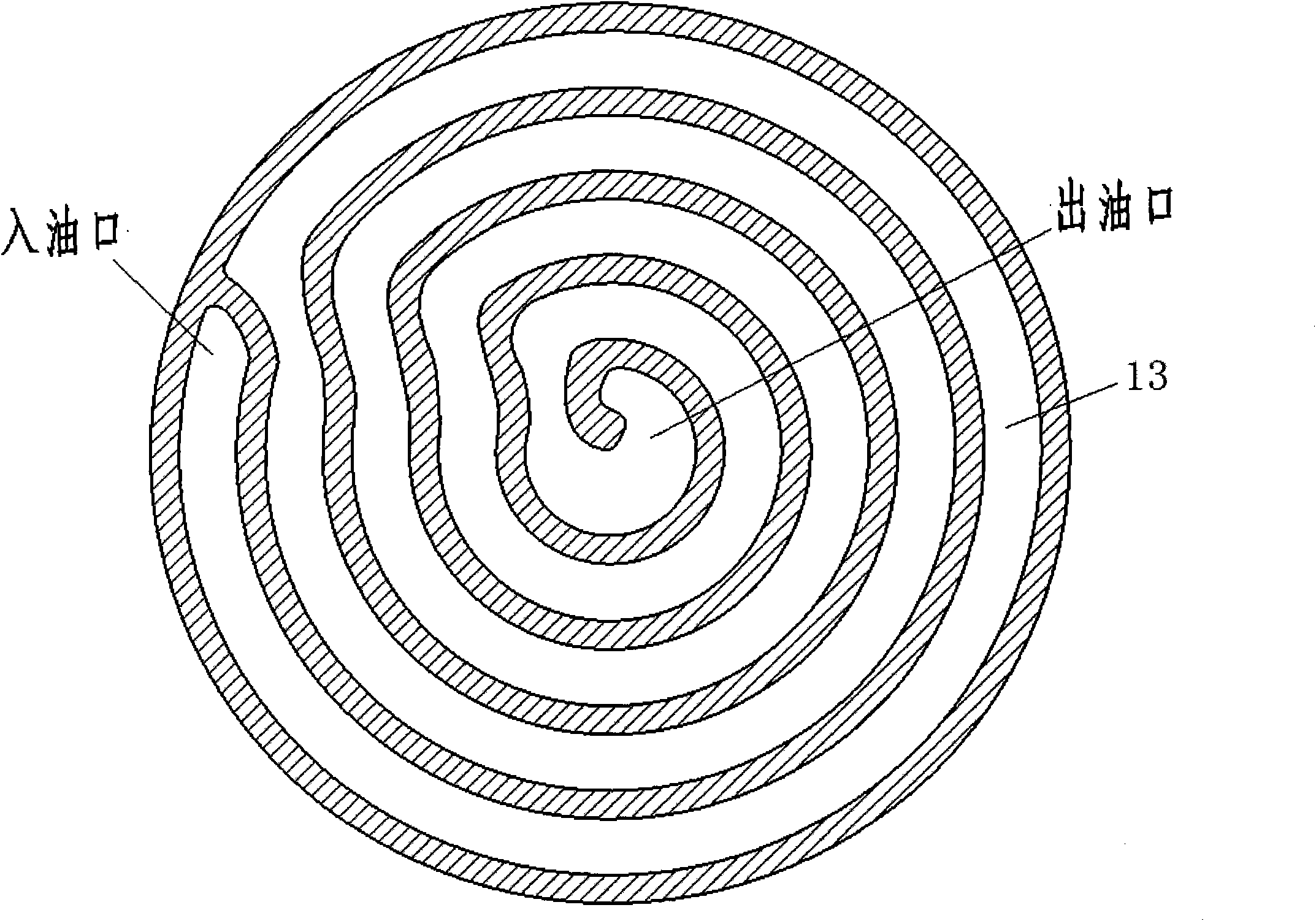

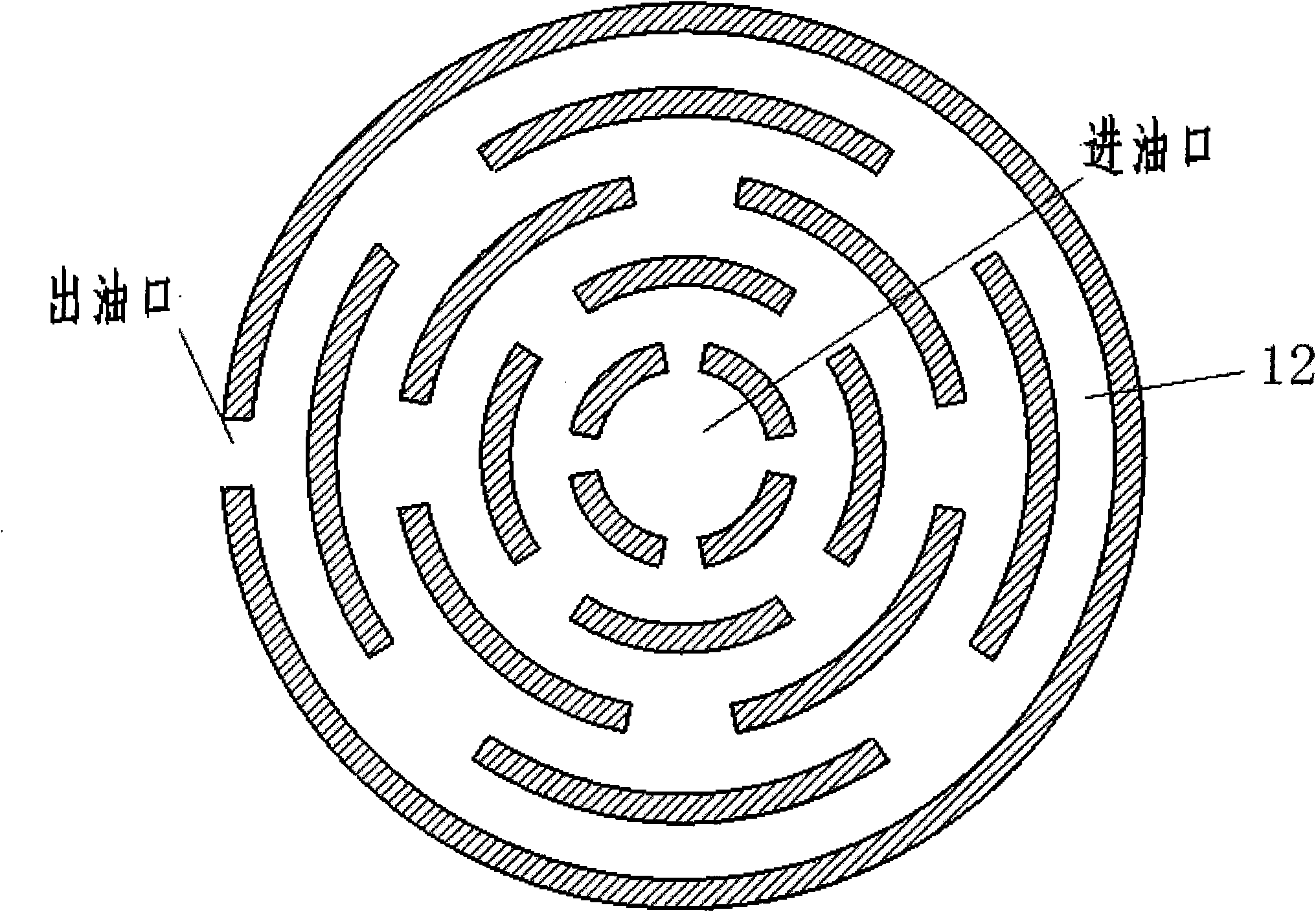

[0015] A chilling plate for cooling and directional solidification of liquid metal, comprising a chilling plate body 1, characterized in that the chilling plate body 1 has an annular channel 13 or a petal-shaped channel 12 for the liquid medium to pass through, the chilling plate body 1 Made of stainless steel or heat-resistant steel.

[0016] The principle of use of the liquid metal cooling directional solidification chiller of the present invention:

[0017] The chilling plate body 1 is fixed on the ceramic casting mold or the casting mold combination 5 with the bottom opening as the bottom of the casting mold to prevent the casting mold from breaking out. The most important thing is that the chilling plate body 1 can be cooled by liquid medium heat transfer oil, and the liquid medium heat transfer oil enters the chilling plate body 1 along the A direction through the inner hollow drawing shaft 2 and flows out along the B direction. In the directional solidification process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com