Energy-saving efficient polysilicon ingot furnace with orientated water cooling and heat dissipation function

A technology of polysilicon ingot casting furnace, water cooling and heat dissipation, applied in polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as difficulty in ensuring thermal uniformity of DS block, increase in heater power, poor seed crystal retention effect, etc. , to achieve the effect of furnace energy saving, reduce the heat loss of the furnace, and achieve the effect of high and uniform cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

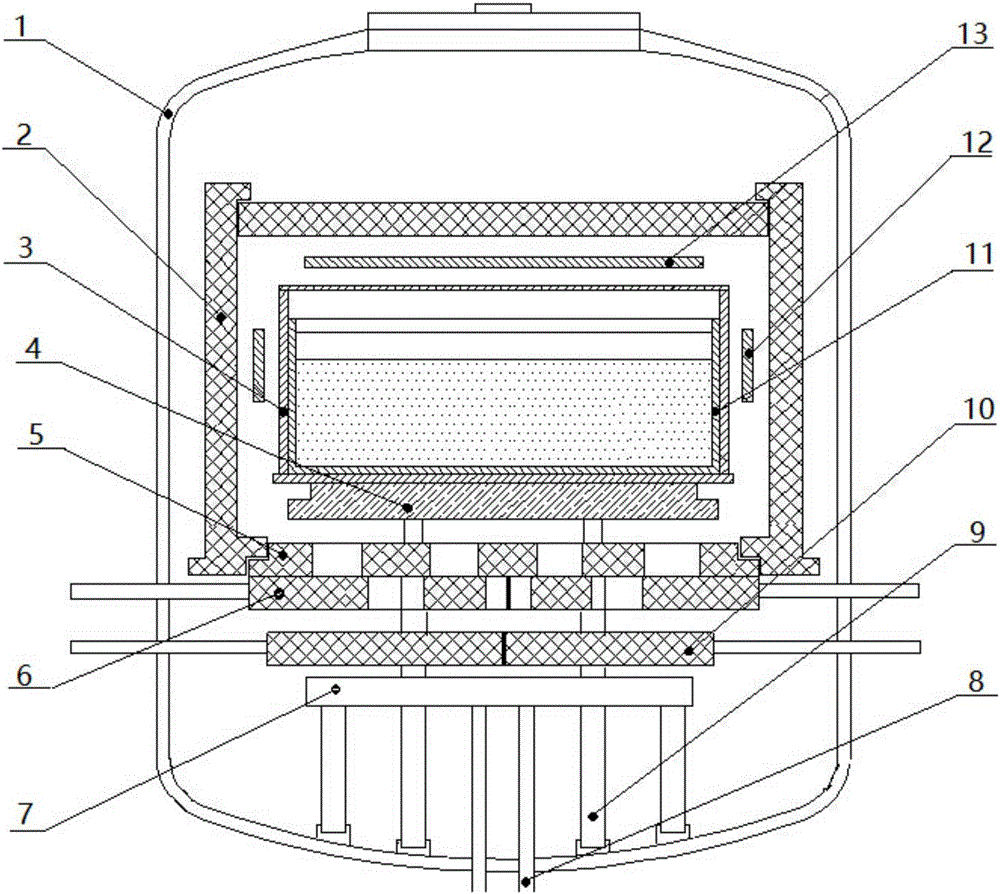

[0022] like figure 1 An energy-saving high-efficiency polysilicon ingot furnace with directional water cooling and heat dissipation is shown, including furnace body 1, heat insulation cage 2, graphite guard plate 3, directional heat dissipation block 4, bottom insulation board 5, heat insulation louvers 6, and water-cooled copper plate 7 , Water-cooled copper tube 8, graphite support column 9, heat insulation sliding door 10, quartz crucible 11, top heater 13, side heater 12.

[0023] The quartz crucible 11 is arranged in the furnace body 1, and a graphite guard plate 3 is installed around the quartz crucible 11; the directional heat dissipation block 4 is installed in the furnace body 1 through a plurality of graphite support columns 9, and is surrounded by a graphite guard plate. The quartz crucible 11 of the plate 3 is installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com