Extrusion molding mold for insulating layer of conducting wire

A wire insulation and insulation layer technology, which is applied in the direction of conductor/cable insulation, household appliances, and other household appliances, can solve the problems of single, unable to extrude two different materials at the same time, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

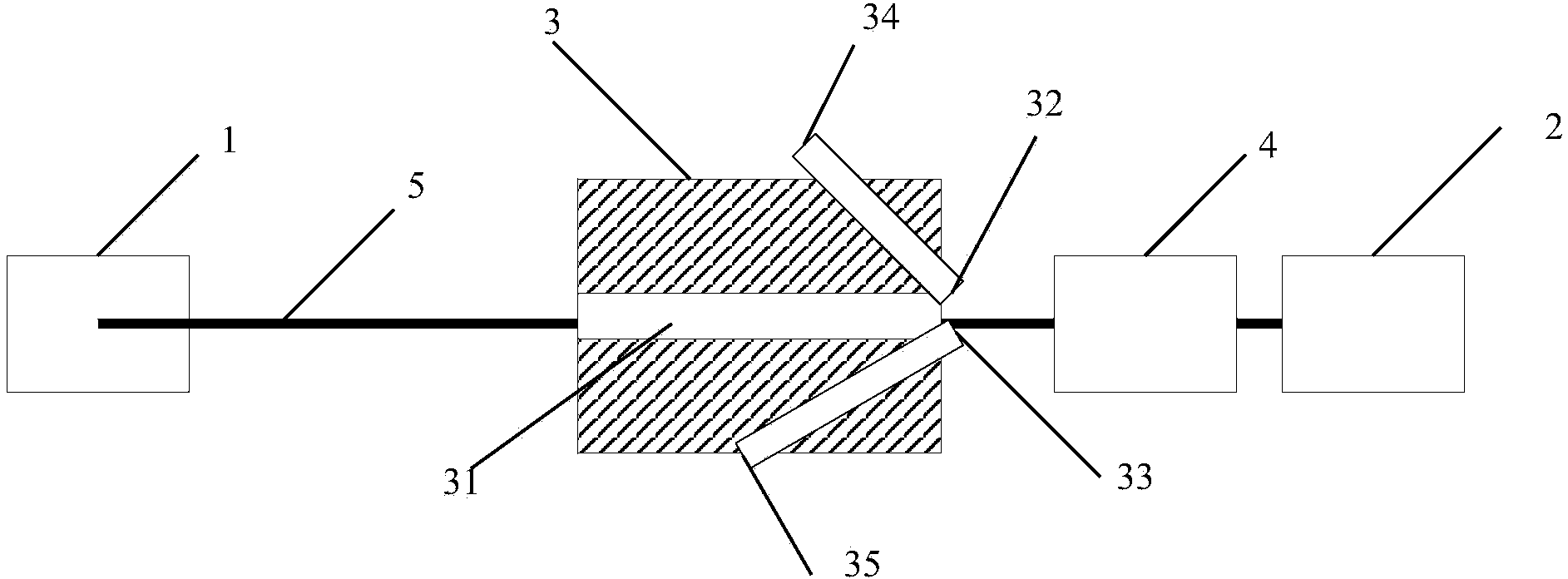

[0017] Such as figure 1 as shown, figure 1 It is a structure diagram of a wire insulation layer extrusion mold in the embodiment of the present invention.

[0018] refer to figure 1 , the embodiment of the present invention provides a wire insulation layer extrusion mold, comprising: a wire releasing part 1, used to release the wire to be extruded; a pulling part 2, used to pull the wire released by the wire releasing part 1; The head 3 of the plastic machine is located between the pay-off part 1 and the traction part 2, and is connected to the processor; the middle of the head 3 of the extruder is provided with a wire channel 31 for the wire 5 to pass through; the extruder The first feed port 34 is also set in the machine head 3, which communicates with the first extrusion port 32 and is used for filling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com