Systems and methods for implementing digital offset lithographic printing techniques

A lithographic offset printing and digital technology, applied in the field of systems and methods for implementing digital lithographic offset printing technology, can solve problems such as damage, high cost, and inability to provide high transfer efficiency costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

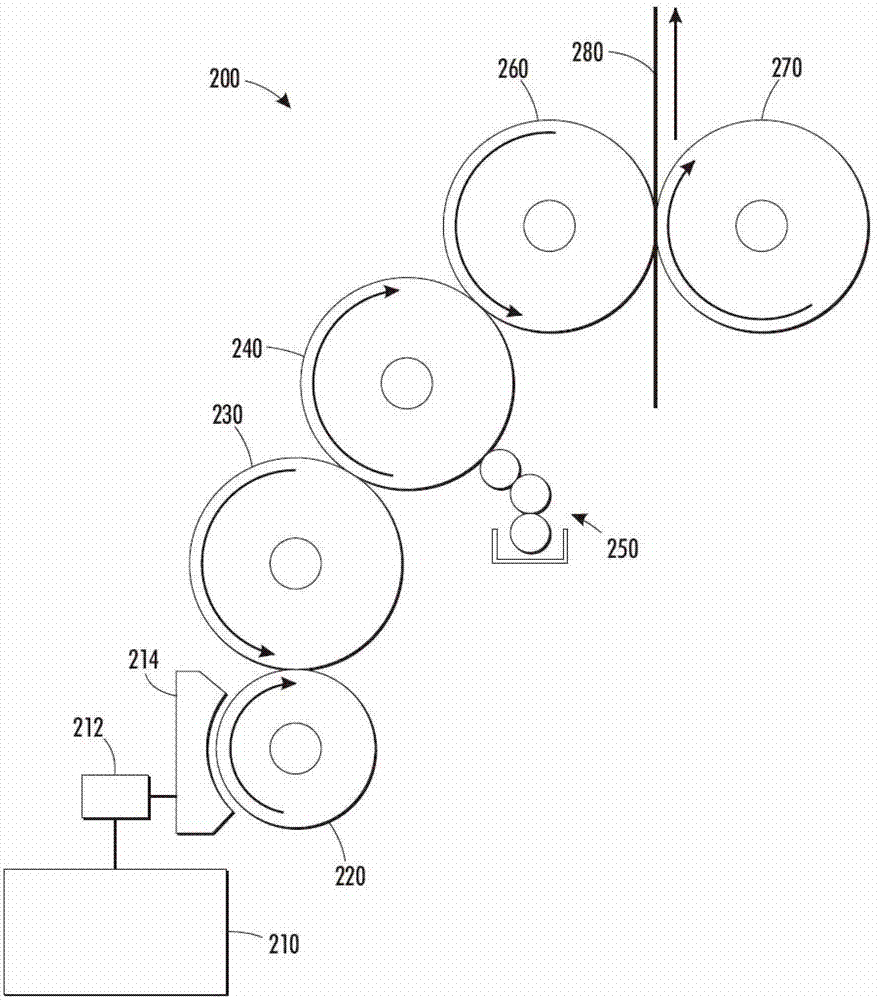

[0030] figure 2 A schematic representation of a conventional lithographic printing system 200 is shown. Such as figure 2 As shown, the inking system may include an ink reservoir 210 , an ink pump 212 and an ink chamber 214 that cooperate to deposit viscous lithographic ink onto an anilox cylinder 220 .

[0031] Anilox ink is well known in the art and refers to a class of inking methods used to provide measured amounts of ink to the ink forming cylinder 230 as well as related inking. In general, the anilox cylinder 220 may be configured as a rigid cylinder, which may have a metal core, for example, and may be coated with a material, such as a ceramic material, that creates printed surface. Anilox cylinder 220 may be partially submerged into an ink fountain such as provided by ink chamber 214 . A thick layer of viscous lithographic liquid may be deposited onto the anilox cylinder 220 . A doctor blade (not shown) may be used to scrape excess ink from the surface of the ani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com