Method for generating resveratrol by converting glucose by using intracellular enzyme of alternaria microorganism

A technology of Alternaria genus and resveratrol, which is applied in the field of converting glucose into resveratrol by intracellular enzymes of Alternaria genus microorganisms, which can solve the problems of long production cycle, large influence on production status, and unstable yield. , to achieve the effects of short production time, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1: Preparation of enzyme solution:

[0049] The Alternaria CCTCC No: M2011348 strain was inoculated into potato juice glucose liquid medium (1000 mL of 20% potato juice, 20 g glucose, natural pH), and cultured at 28°C and 120 rpm for 4 days. Take the culture to collect the mycelium by filtration, and rinse it with distilled water. The obtained mycelium was ground and broken in liquid nitrogen, and the enzyme extract (50mmol / L pH=7 phosphate buffer solution, 0.1g / L magnesium sulfate was added at the ratio of 8 ml crude enzyme extract per 4.0 g of bacteria , 0.2g / L calcium sulfate, 0.6mmol / L DTT). After mixing uniformly, centrifuge at 4°C and 1000 rpm for 10 min, and collect the supernatant. Add solid ammonium sulfate to the supernatant to its saturation concentration of 75%, let it stand overnight at 4°C and centrifuge at 1000rpm for 10 minutes, collect the precipitate and dissolve it with the enzyme extract, put it into a dialysis bag, and dialyze at 4°C until nothi...

Embodiment 2

[0057] Step 1: Preparation of enzyme solution:

[0058] The same as in Example 1.

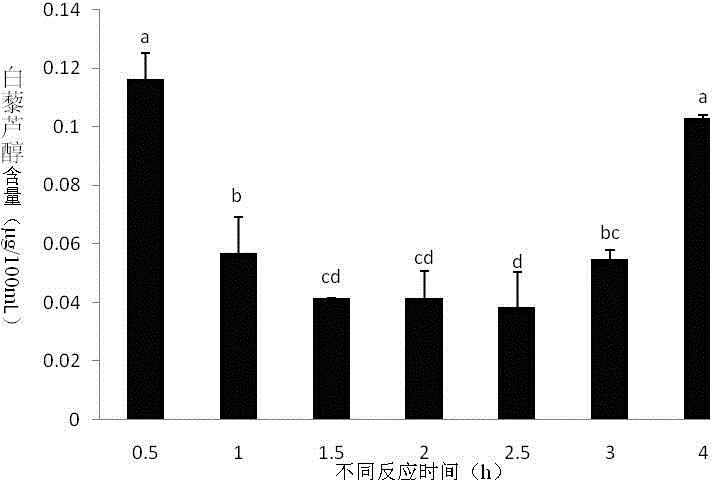

[0059] Step 2: Generate resveratrol:

[0060] Take 100 mL of 50 mmol / L pH 7.0 phosphate buffer solution containing 0.1 g / L magnesium sulfate, 0.2 g / L calcium sulfate and 1 mmol / L glucose, add 5 mL of crude enzyme solution, and place it at 37°C and 120 rpm After reacting for 0.5 to 4 hours, mass spectrometry and high performance liquid chromatography were used to qualitatively and quantitatively analyze the resveratrol production in the reaction solution at different times.

[0061] Mass spectrometry and high performance liquid chromatography were used to qualitatively analyze the yield of resveratrol: the same as in Example 1.

[0062] Experimental results:

[0063] The content of resveratrol at 0.5 h and 4.0 h was much higher than other reaction times, indicating that it only takes 0.5 h to obtain higher resveratrol yield. The reaction efficiency is greatly improved.

Embodiment 3

[0065] Step 1: Preparation of enzyme solution:

[0066] The same as in Example 1.

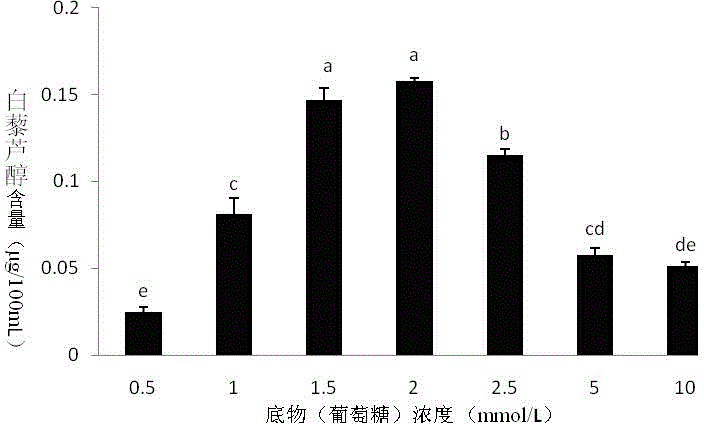

[0067] Step 2: Generate resveratrol:

[0068] Take 100 mL of 50 mmol / L pH 7.0 phosphate buffer solution containing 0.1 g / L magnesium sulfate, 0.2 g / L calcium sulfate and different concentrations of glucose (0.5, 1.0, 1.5, 2.0, 2.5, 5.0, 10.0 mmol / L), Add 5 mL of crude enzyme solution, react for 0.5 h at 37°C and 120 rpm, and then use mass spectrometry and high performance liquid chromatography to qualitatively analyze the resveratrol output in the reaction solution.

[0069] Mass spectrometry and high performance liquid chromatography were used to qualitatively analyze the yield of resveratrol: the same as in Example 1.

[0070] Experimental results:

[0071] When the glucose concentration was 2.0 mmol / L, resveratrol produced the highest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com